Preparation method of lignosulphonate proton exchange membrane material

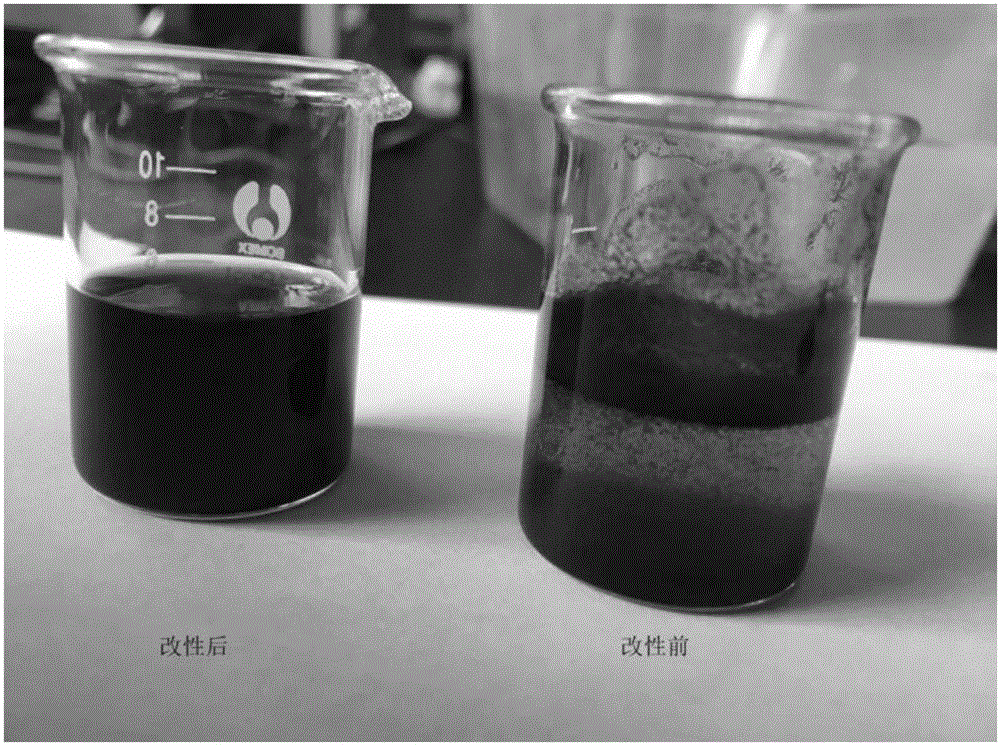

A technology of lignosulfonate and proton exchange membrane, which is applied in fuel cells, electrochemical generators, electrical components, etc., can solve the problems of high cost of proton exchange membranes, few sources of materials, and environmental pollution. Low cost, wide source of raw materials, and the effect of improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Dissolve 8 g of sodium lignosulfonate powder in 40 ml of deionized water at room temperature, stir it thoroughly, filter to remove insoluble solid impurities, and add an aqueous solution of sodium lignosulfonate to a three-necked flask.

[0038] 2) access protection N 2 , at N 2 Add 0.32 g of ammonium persulfate under the atmosphere, stir (rotating speed 120 r / min), and raise the temperature to 80°C.

[0039] 3) Keep the stirring rate constant at 120r / min, use a constant pressure dropping funnel to drop 2g of styrene and 2.4g of grafted comonomer methyl acrylate at the same speed within 20min, and react for 24h after the addition .

[0040] 4) Cool the mixed liquid obtained in step 3) to room temperature, let it stand for 1 hour, and use a rotary evaporator to evaporate water, unreacted styrene, and comonomers to obtain solid powder.

[0041] 5) The solid powder obtained in step 4) was sequentially washed with water, extracted with methanol, and vacuum-dried to re...

Embodiment 2

[0052] 1) Dissolve 8 g of sodium lignosulfonate powder in 40 ml of deionized water at room temperature, stir it thoroughly, filter to remove insoluble solid impurities, and add an aqueous solution of sodium lignosulfonate to a three-necked flask.

[0053] 2) access protection N 2 , at N 2 Add 0.32 g of ammonium persulfate under the atmosphere, stir (at a speed of 120 r / min), and raise the temperature to 80°C.

[0054] 3) Keep the stirring rate constant at 120r / min, and use a constant pressure dropping funnel to successively add 2g of styrene and 2.4g of grafted comonomer methyl acrylate at the same speed within 20min, and the addition is complete Reaction after 24h.

[0055] 4) Cool the mixed liquid obtained in step 3) to room temperature, let it stand for 1 hour, and use a rotary evaporator to evaporate water, unreacted styrene, and comonomers to obtain solid powder.

[0056] 5) The solid powder obtained in step 4) was successively washed with water, extracted with methano...

Embodiment 3

[0061] 1) Dissolve 8 g of sodium lignosulfonate powder in 40 ml of deionized water at room temperature, stir it thoroughly, filter to remove insoluble solid impurities, and add an aqueous solution of sodium lignosulfonate to a three-necked flask.

[0062] 2) access protection N 2 , at N 2 Add 0.32 g of ammonium persulfate under the atmosphere, stir (rotating at 120 r / min), and heat up to 80°C.

[0063] 3) Keep the stirring rate constant at 120r / min, and use a constant pressure dropping funnel to drop successively 2g of styrene and 2.4g of grafted comonomer methyl acrylate at the same speed within 20min. Reaction 24h.

[0064] 4) Cool the mixed liquid obtained in step 3) to room temperature, let it stand for 1 hour, and use a rotary evaporator to evaporate water, unreacted styrene, and comonomers to obtain solid powder.

[0065] 5) The solid powder obtained in step 4) was successively washed with water, extracted with methanol, and vacuum-dried to remove unreacted sodium lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

| Proton conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com