Municipal garbage automatic processing system

A treatment system and municipal waste technology, applied in the field of municipal waste treatment devices, can solve the problems of large investment, low waste utilization rate, secondary pollution, etc., and achieve the effect of less investment and reduction of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

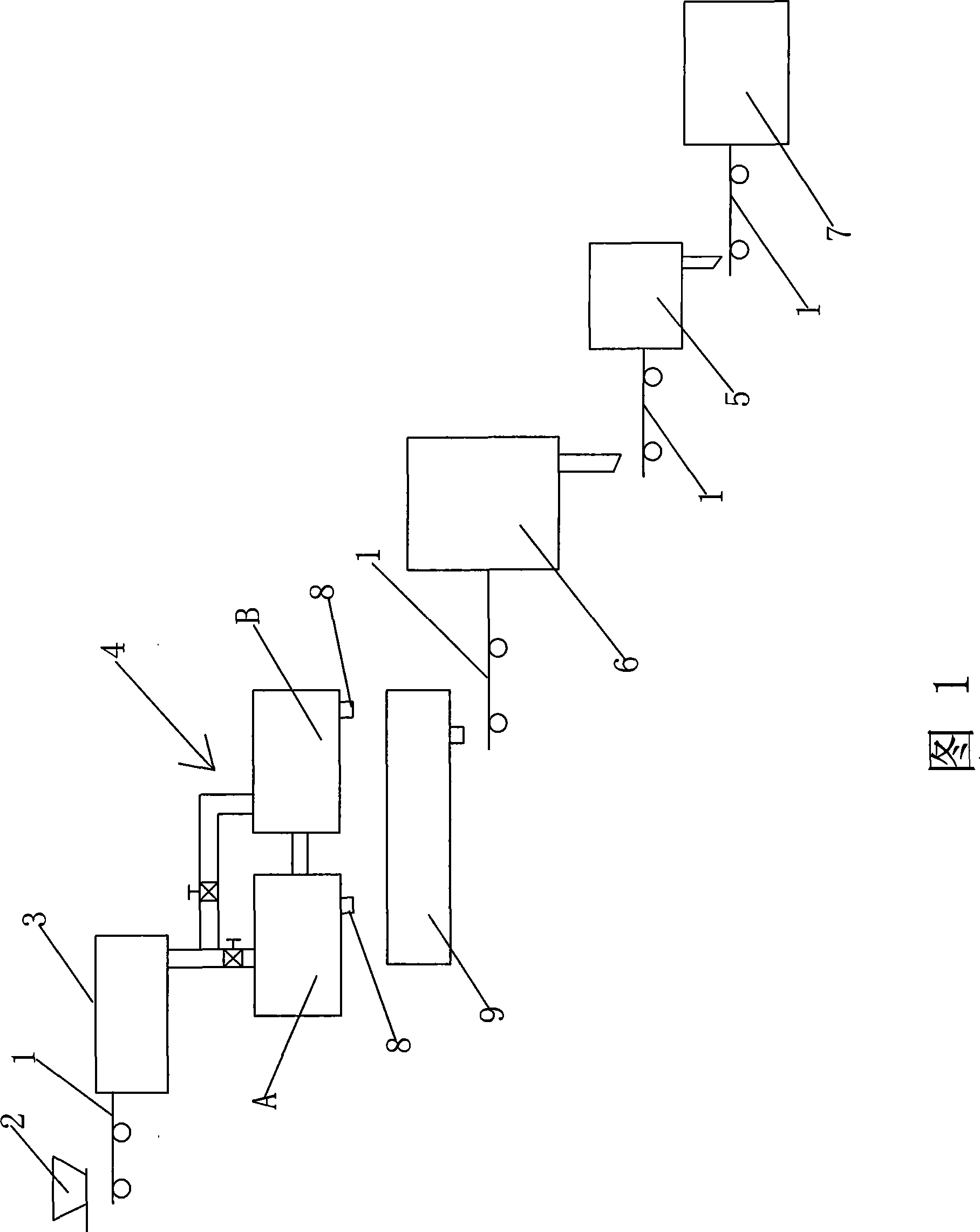

[0013] The urban garbage automatic processing system includes a belt conveyor 1, a high-level hopper 2, a magnetic separator 3, a biogas digester 4, a pulverizer 5, a drying furnace 6, a centrifuge 9 and a brick making machine 7.

[0014] After the garbage is sorted by hand, it is sent to the high-level hopper 2, and is transported to the magnetic separator by the belt conveyor 1 for magnetic separation. After the iron-containing substances are separated, it is sent to the biogas generator for fermentation, and the generated biogas is transported through the biogas The pipeline is sent to the drying furnace as a heat source, and the remaining biogas is transported to the user through the pipeline. The remaining waste after biological fermentation in the biogas digester will be discharged when the accumulation height in the biogas digester reaches 1 / 2. Digester 4 is a letter fermentation tank. When the mother fermentation tank A is blowing down, the fermented liquid in the mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com