Metal magnetic conduction ceramic pot

A technology of ceramic pots and magnetic conduction, applied in the direction of special materials for cooking utensils, etc., can solve the problems of unaffordable prices, poor conductivity, and increased impedance of civilian products, achieve good low-impedance conductivity, increase electromagnetic induction, and reduce resistance rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

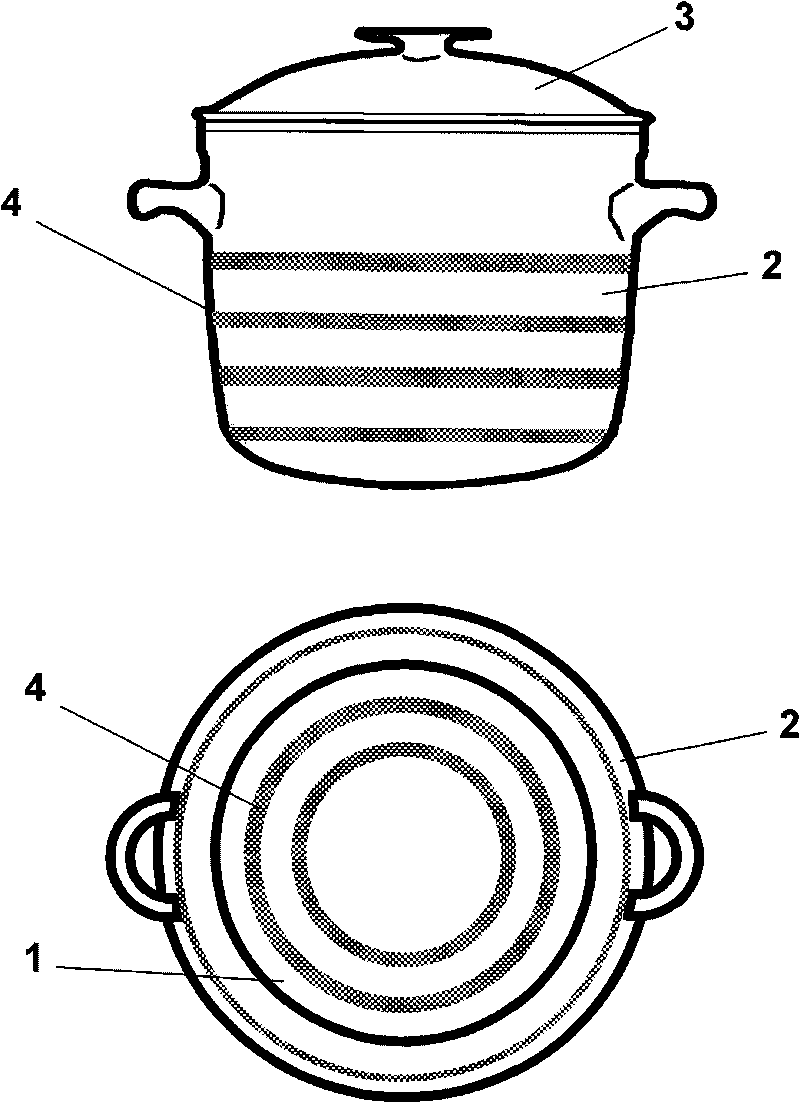

[0053] As shown in the figure, the structure is specifically described as the preferred embodiment of the present invention for implementation:

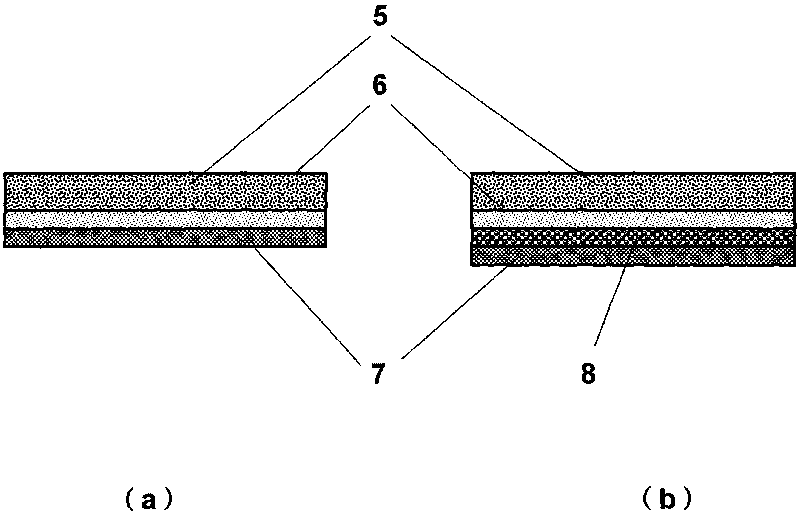

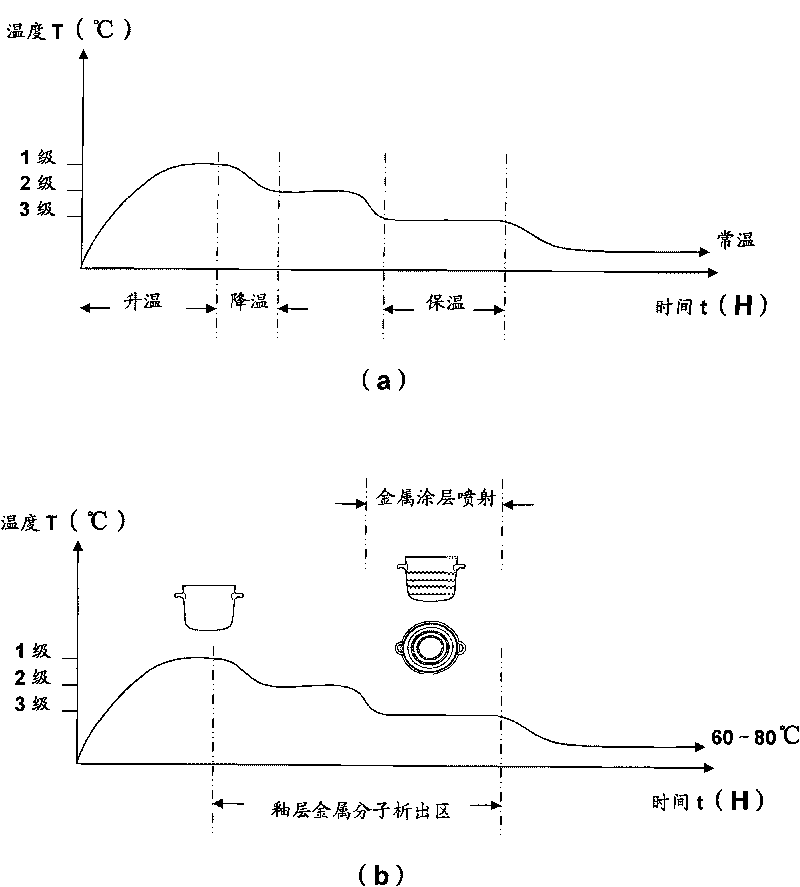

[0054]Considering the anchoring effect of the metal molecules between the pottery, the glaze, and the annular metal magnetic conductive coating 4, in the making of the pottery clay body, the present invention first samples and analyzes the adobe, and adds a certain proportion of copper ( Cu), iron (Fe), aluminum (Al), nickel (Ni), manganese (Mn), tungsten (W), graphite (C), etc., made into embryo base powder, after sieving, grinding, ultrasonic homogenization , the workpiece 9 is formed, and the workpiece 9 is demoulded. In order to obtain more precipitation of metal molecular clusters at the bottom of the workpiece 9, the firing position of the upper and lower sides of the mouth is adopted and pushed into the electric kiln. In order to prevent the metal in the embryo body from Oxidation of the components enhances the reduction react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com