Super-thin wall bottle-gourd shaped milk bottle made of high borosilicate glass and its making method

A high borosilicate glass, gourd-shaped technology, applied in glass manufacturing equipment, glass blowing, glass forming, etc., can solve the problems of increasing ambient temperature and noise, large and complex equipment, and many processes, and achieve simplification of forming equipment, Beautiful shape, thin and uniform bottle wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

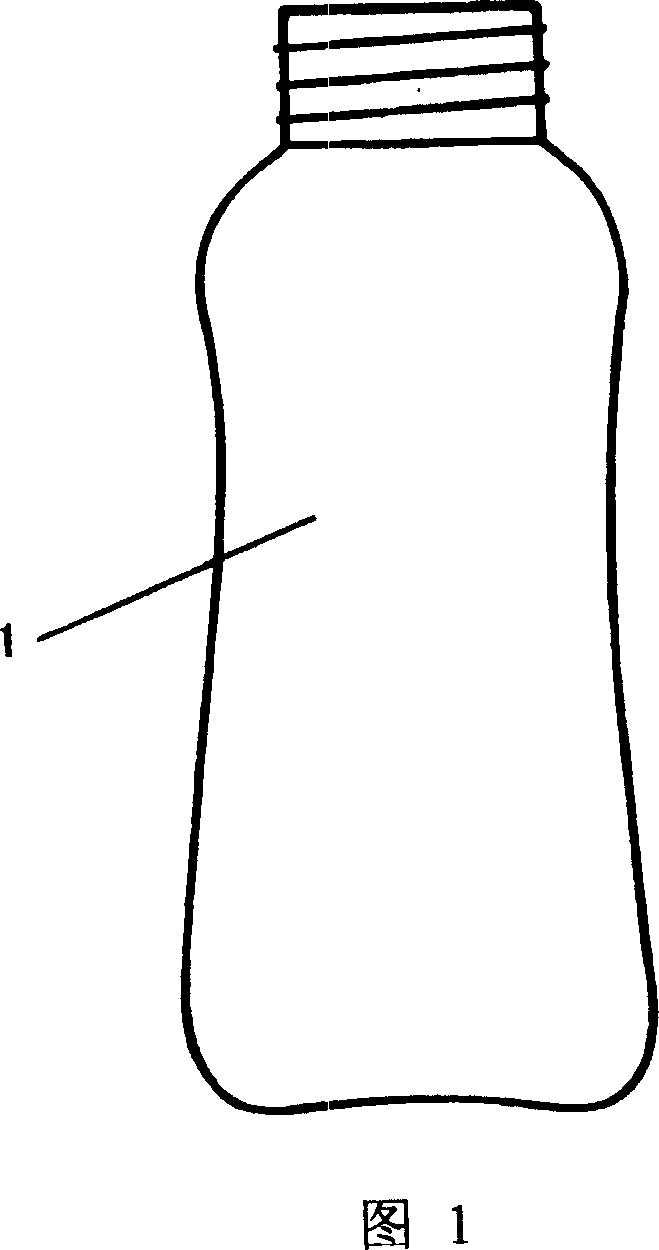

[0025] Represented by Fig. 1 is the embodiment of the present invention - high borosilicate glass ultra-thin gourd-shaped feeding bottle. The feeding bottle 1 is made of high borosilicate glass and is shaped like a gourd. The height of this embodiment is 15 centimeters, the diameter of the thickest part is 6.5 centimeters, the wall thickness of the bottle body is only 1.8 millimeters, and the weight is only 90 grams.

[0026] This embodiment is transparent, the inside and outside of the bottle are smooth and smooth, there is no mold stitching, and it is easy to clean, and it will not leave milk particles and bacteria like PC plastic milk bottles because the inner wall of the bottle is not smooth; because high borosilicate glass is not easy to burst under sudden temperature changes, Therefore, it will not burst when brewed with boiling water in a temperature environment below zero Celsius, and can be sterilized by steam at high temperature, so it is very safe to use; in addition...

Embodiment 2

[0028] The following is an embodiment of a method for making a high borosilicate glass ultra-thin gourd-shaped feeding bottle.

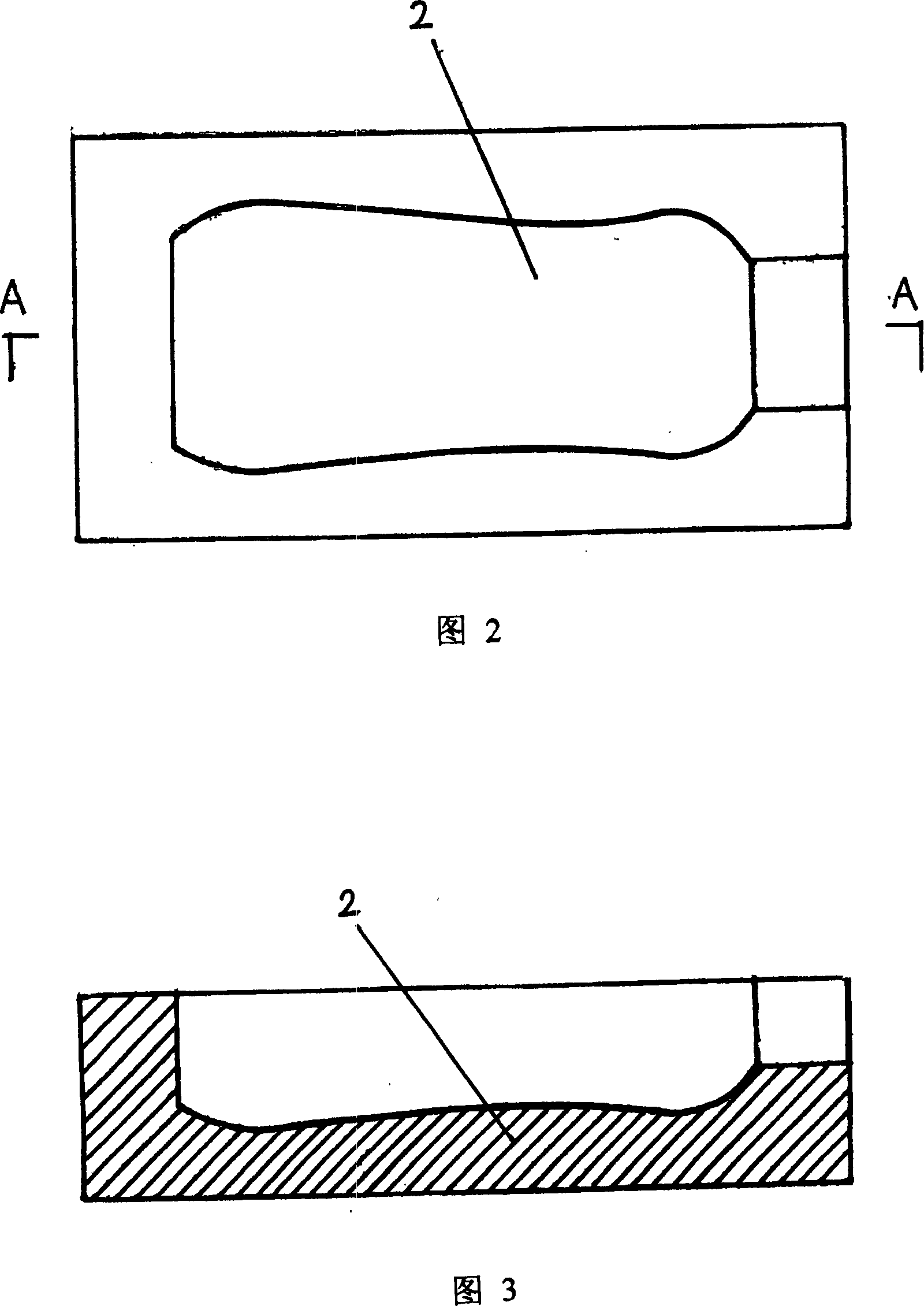

[0029] The product of this embodiment is exactly the above-mentioned embodiment one, i.e. the feeding bottle 1 . It adopts a high borosilicate glass tube with a diameter of 60 mm, cut into a segmented glass cylinder with a length of 180 mm; then put it into a heating furnace and heat it at a high temperature until softened, and then place it on the longitudinal half of the gourd-shaped bottle body On the mold 2, while blowing, rotate it to make it reach the shape of the gourd-shaped feeding bottle body and the required thickness. The required thickness of the bottle body is 1.8 mm; then put the gourd-shaped feeding bottle body into the heating furnace to heat until softened Condition, after the bottle is out of the oven, use the half-closed forming mold to blow the head of the bottle body into the shape of the bottle mouth; then use a mechanical grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com