Mould for manufacturing bottle glass vessels

A technology for glass containers and bottles, which is applied in glass blowing, glass forming, manufacturing tools, etc. It can solve the problems of undefined bottle necks and shoulders, and achieve the effect of deformation suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

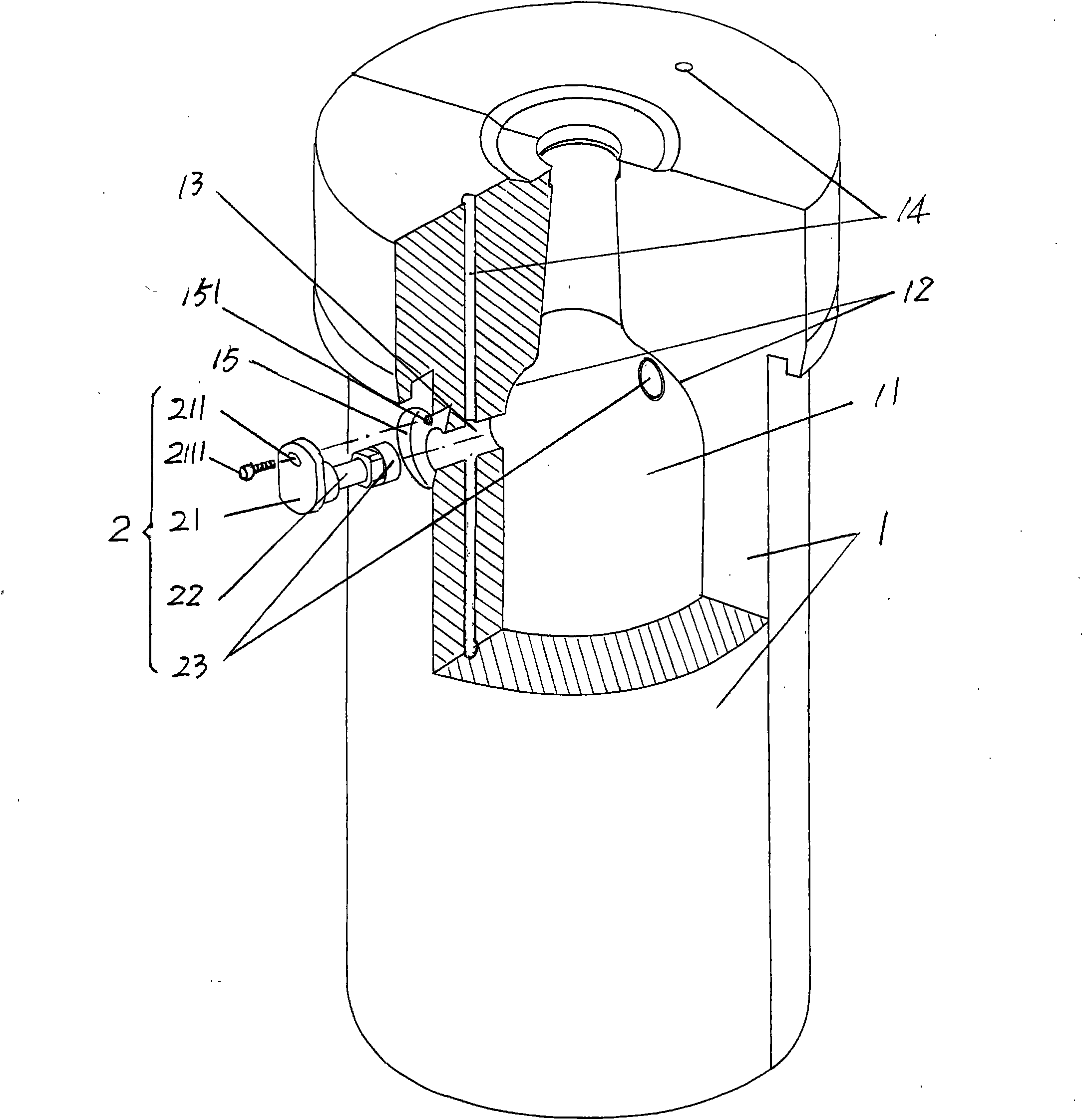

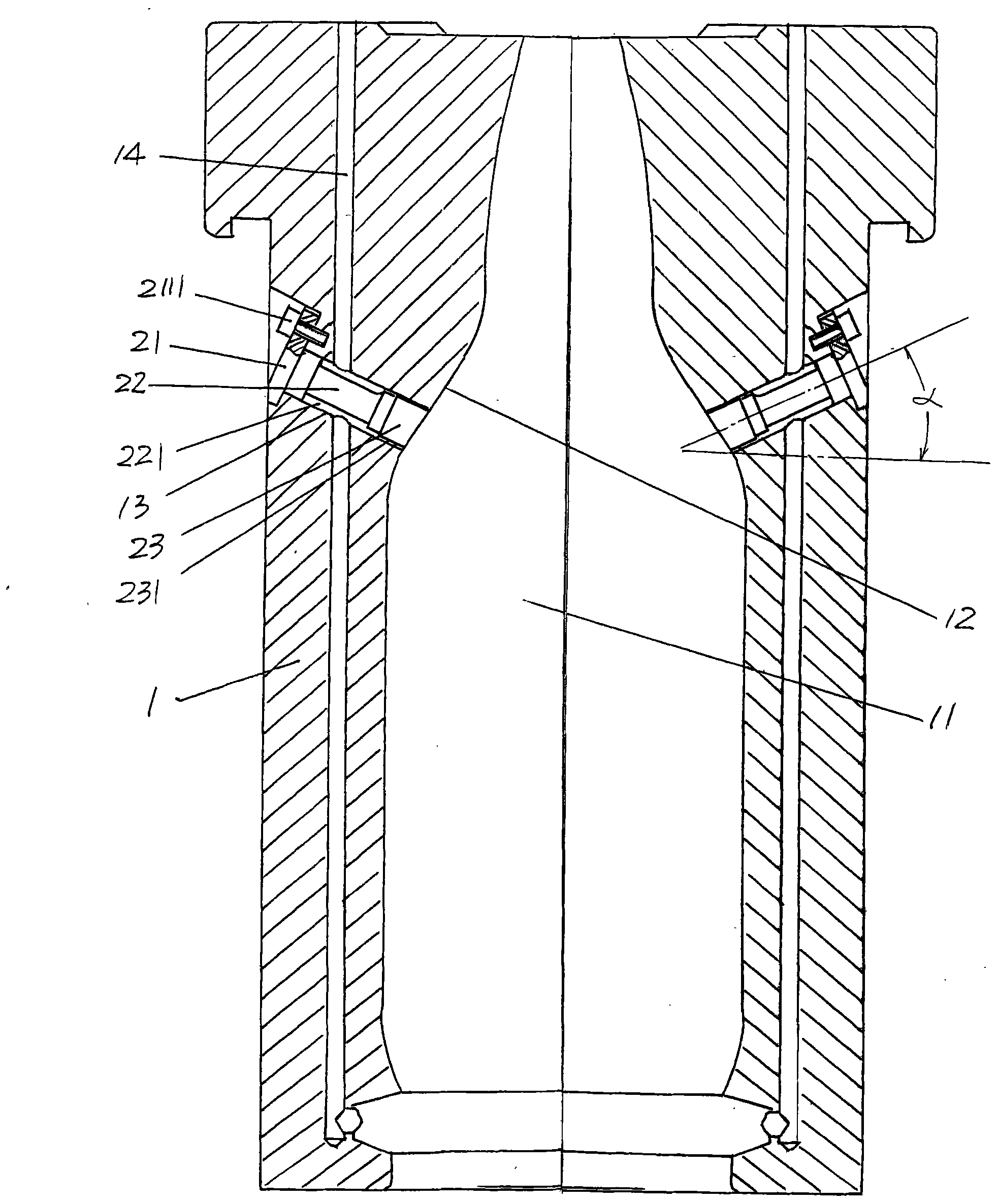

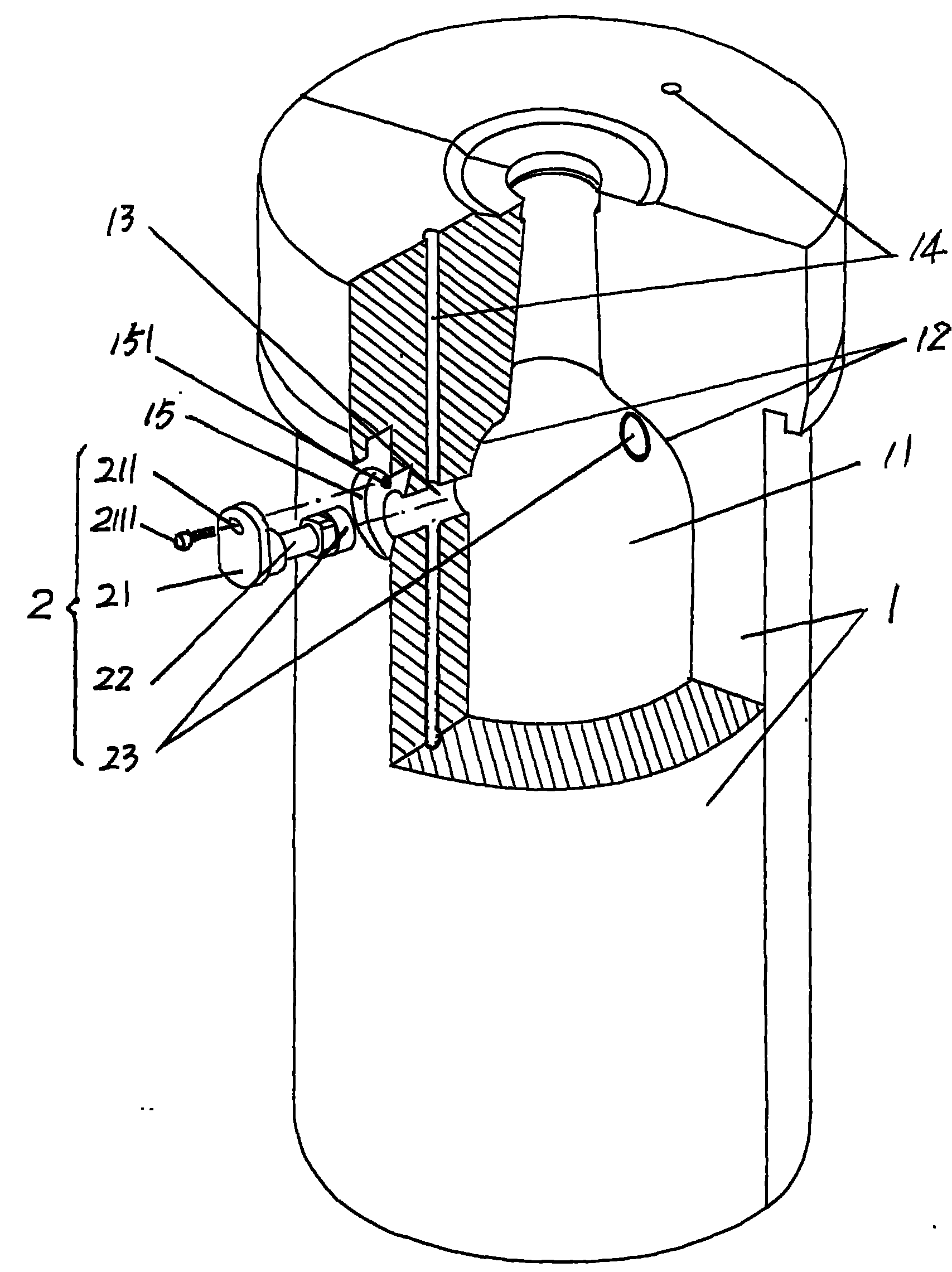

[0016] please see figure 1 and figure 2 , provides the mold that is used for making bottle type glass container, and this mold is made of a pair of bottle half molds 1 that each have bottle half mold cavities 11 that are identical in shape and structure. As the technical gist of the present invention: a valve hole 13 is provided on a pair of bottle half molds 1 and at the neck shoulder 12 of the bottle half mold 1. The valve hole 13 is located at the aforementioned neck shoulder 12 and at the bottle half The middle part of the width direction of the mold 1 is the middle part of the neck shoulder 12, and the valve hole 13 communicates with the bottle half cavity 11. The preferred solution is to set the valve hole 13 obliquely on the half-mould 1 of the bottle, specifically: an inclination angle α (also known as the horizontal line) is formed between the central axis of the valve hole 13 and the axial horizontal line of the aforementioned neck shoulder 12 (i.e. the aforementio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com