A large-scale preparation method of superhydrophobic surface of aluminum foil fin group of heat exchanger

A super-hydrophobic surface, fin group technology, applied in ion implantation plating, coating, metal material coating process and other directions, can solve the problems of difficult to large-scale application, difficult to prepare large area, difficult to prepare on a large scale, etc. Achieve the effect of reducing damage, uniform performance and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

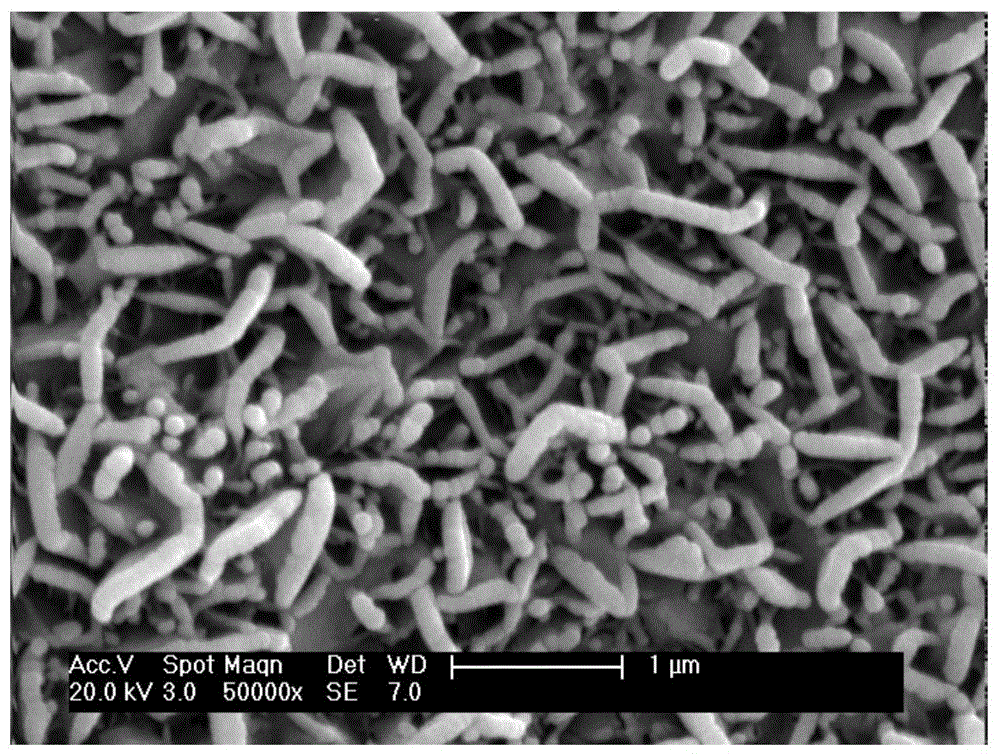

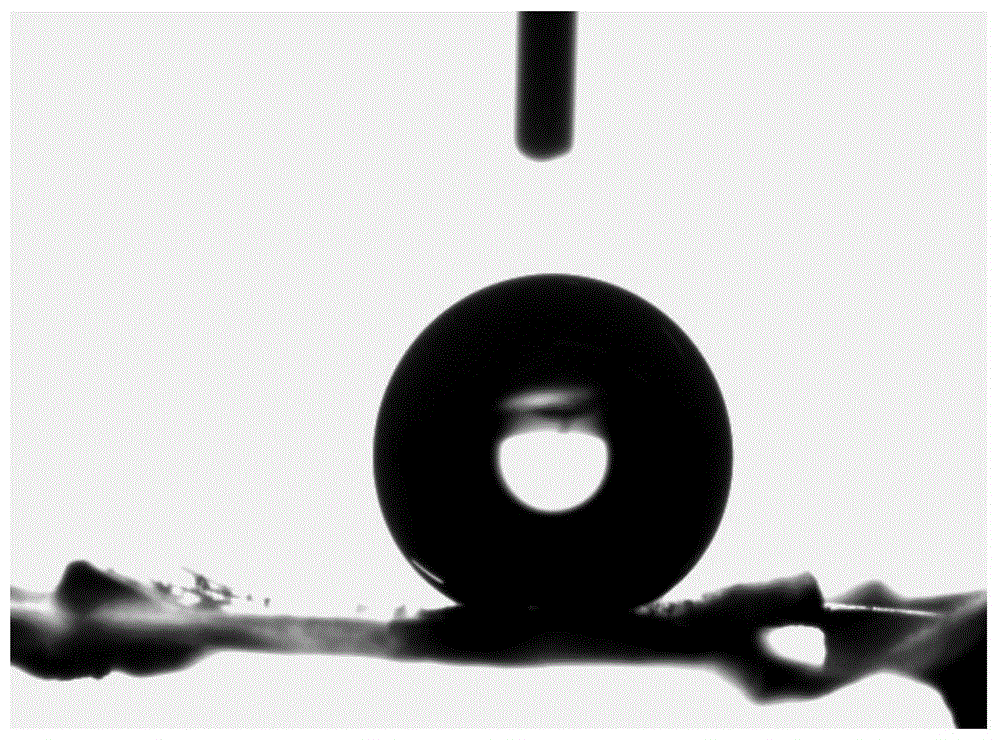

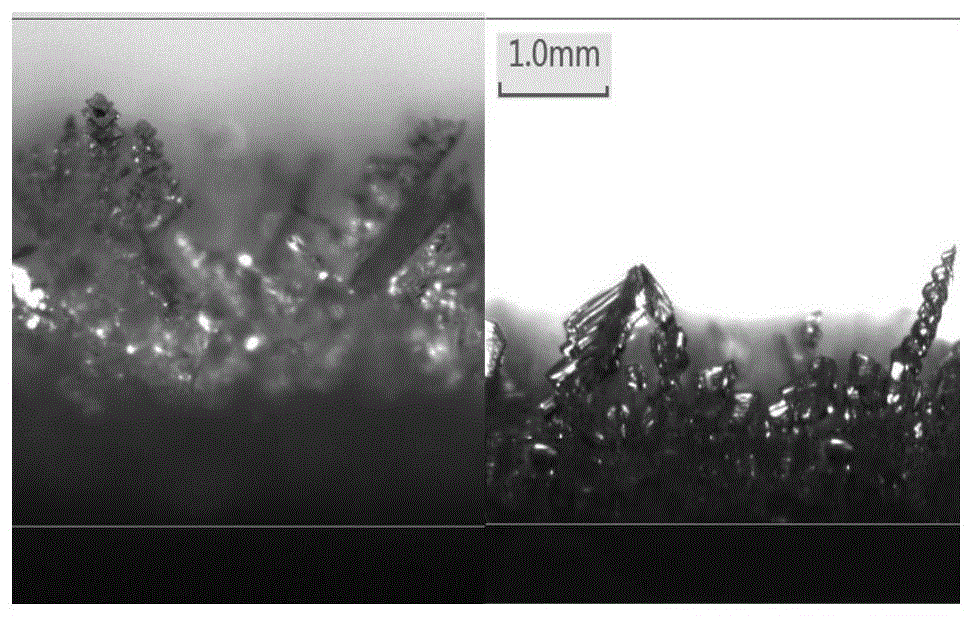

[0041] (1) Pretreatment: ultrasonically clean the aluminum foil fin group of the heat exchanger with acetone and deionized water, blow dry, immerse in 1mol / L sodium hydroxide aqueous solution, treat at room temperature for 30s, and then wash with ethanol and deionized water in sequence. Rinse with water, dry and set aside; the aluminum element content of the aluminum foil fins of the heat exchanger is more than 99.0wt%, and the number of fins is more than 10;

[0042] (2) Etching treatment: using the mixed aqueous solution of hydrochloric acid and glycerol as the etching solution, put the aluminum foil fins of the heat exchanger in a group of close-packed groups in the etching solution under the condition of a water bath at 40°C, and etch The time is 120s. After the etching is finished, the aluminum foil is taken out, cleaned with ethanol and deionized water and blown dry. The mixed aqueous solution of hydrochloric acid and glycerin is prepared by the following method: analytic...

Embodiment 2

[0047] (1) Pretreatment: ultrasonically clean the aluminum foil fin group of the heat exchanger with acetone and deionized water, dry it, and immerse it in 1mol / L sodium hydroxide aqueous solution, treat it at room temperature for 60s, and then wash it with ethanol, deionized water, etc. Rinse with water, dry and set aside; the aluminum element content of the aluminum foil fins of the heat exchanger is more than 99.0wt%, and the number of fins is 30 pieces;

[0048] (2) Etching treatment: using the mixed aqueous solution of sodium hydroxide and glycerol as the etching solution, put the closely packed aluminum foil fins of the heat exchanger in the etching solution under the condition of 60°C water bath, The etching time is 80s. After the etching is finished, take out the aluminum foil, wash it with ethanol and deionized water and blow it dry. The mixed aqueous solution of sodium hydroxide and glycerol is prepared by the following method: sodium hydroxide analytically pure and ...

Embodiment 3

[0052] (1) Pretreatment: ultrasonically clean the aluminum foil fin group of the heat exchanger with acetone and deionized water, dry it, and immerse it in 1mol / L sodium hydroxide aqueous solution. Rinse with water, dry and set aside; the aluminum element content of the aluminum foil fins of the heat exchanger is more than 99.0wt%, and the number of fins is 50 pieces;

[0053] (2) Etching treatment: using the mixed aqueous solution of hydrochloric acid and glycerol as the etching solution, put the closely packed aluminum foil fins of the heat exchanger in the etching solution under the condition of a water bath at 60°C, and etch The time is 90s. After the etching is finished, take out the aluminum foil, wash it with ethanol and deionized water and blow it dry. The mixed aqueous solution of hydrochloric acid and glycerin is prepared by the following method: add analytically pure hydrochloric acid and glycerin to remove In deionized water, a mixed aqueous solution of hydrochlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com