Cu-Ni-Si COPPER ALLOY SHEET AND MANUFACTURING METHOD

一种铜合金、板材的技术,应用在金属轧制等方向,能够解决蚀刻面表面平滑性得不到能够满足需要等问题,达到尺寸精度优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

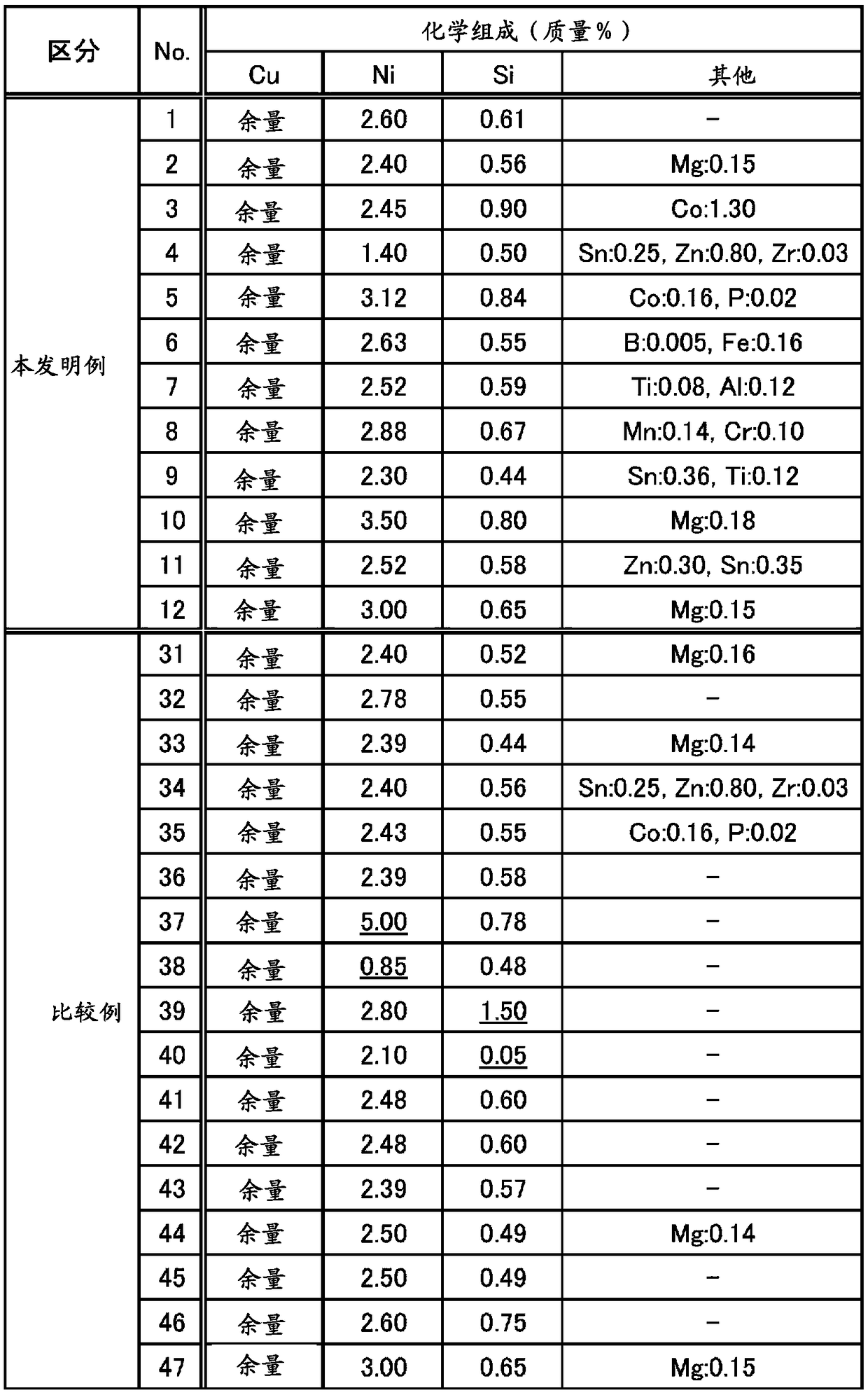

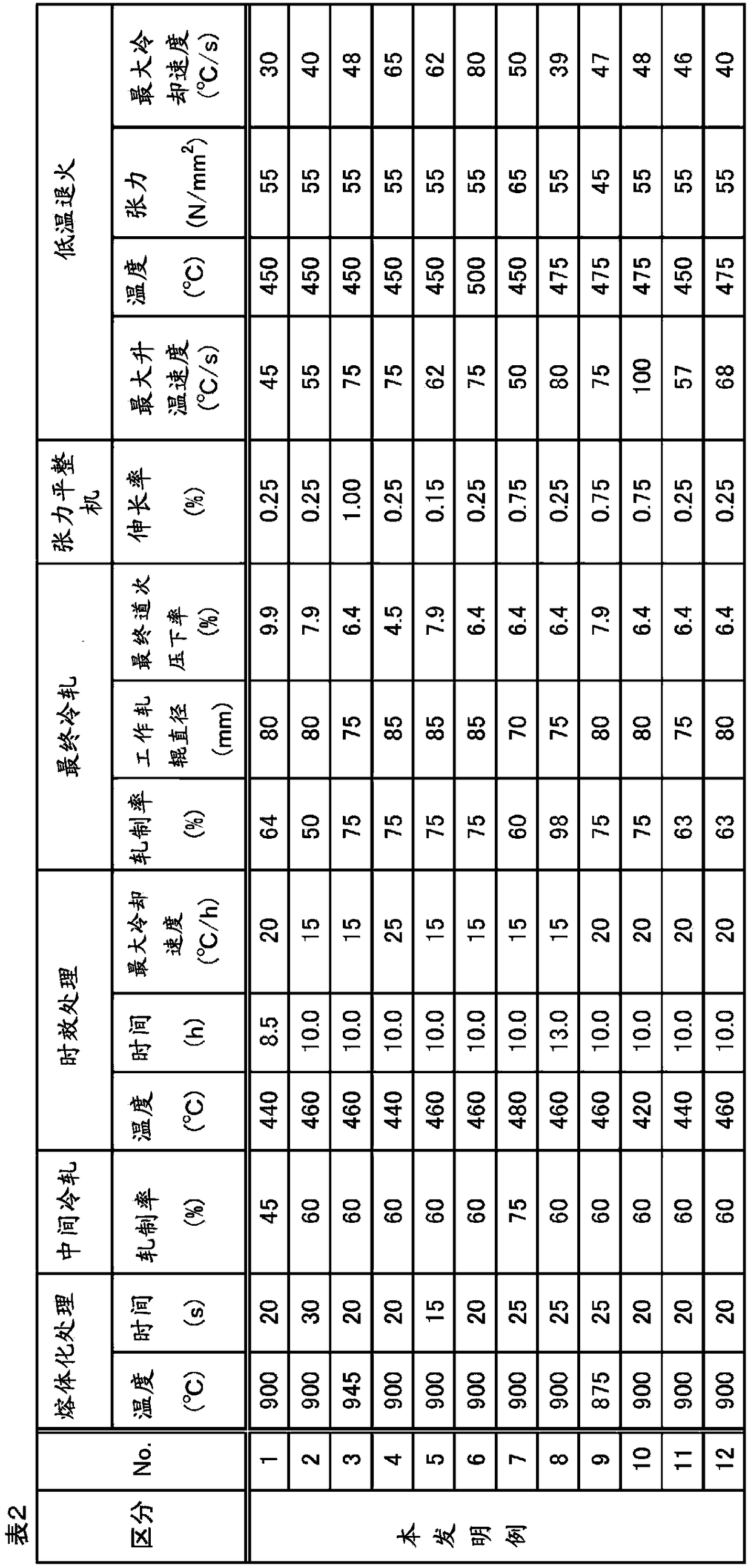

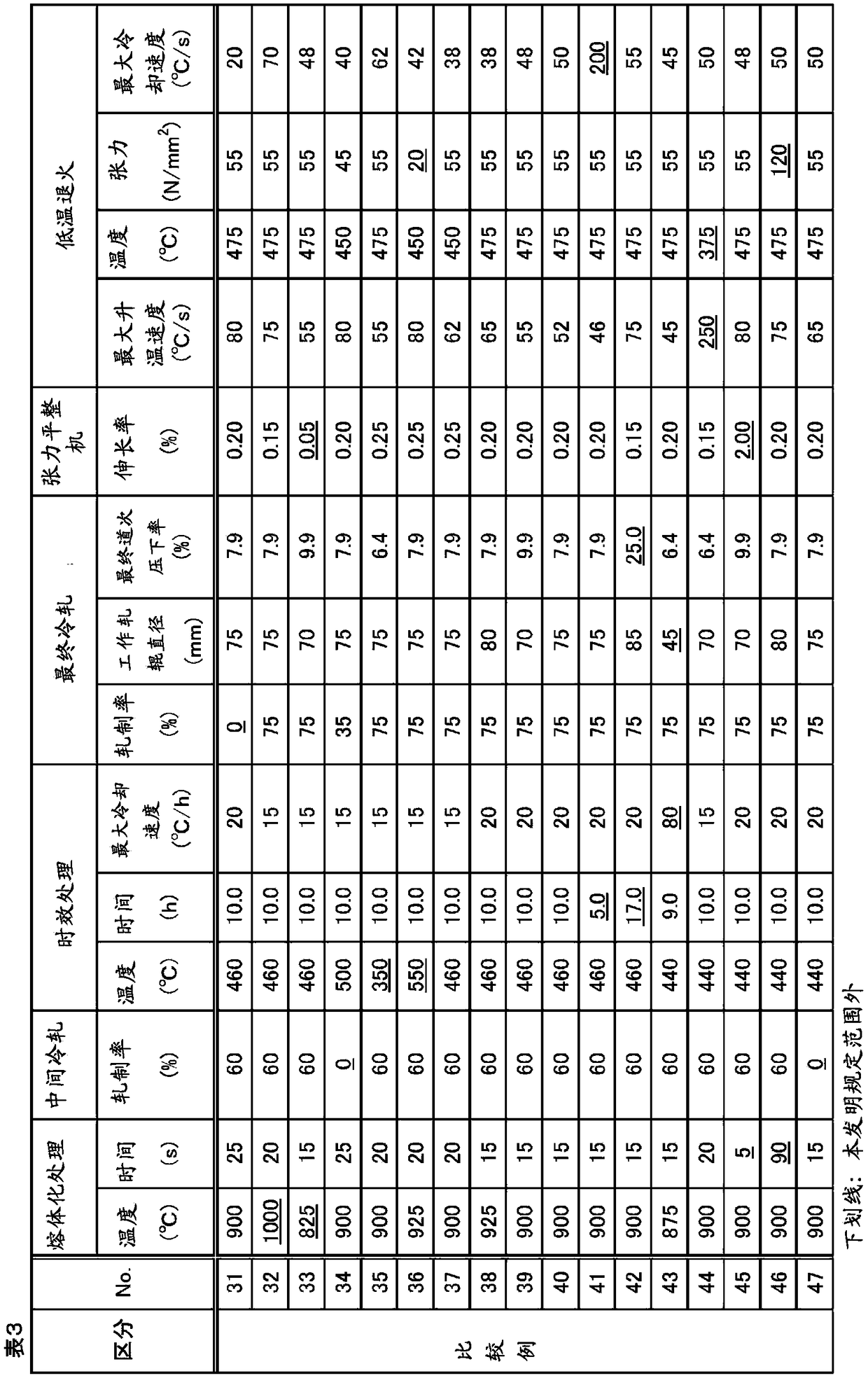

[0096] Copper alloys having the chemical compositions shown in Table 1 were melted and cast using a vertical semi-continuous casting machine. The obtained slab was heated at 1000° C. for 3 hours, extracted, hot-rolled to a thickness of 14 mm, and cooled with water. The total hot rolling ratio is 90 to 95%. After the hot rolling, the oxide layer on the surface layer was removed by mechanical grinding (face grinding), and 80 to 98% cold rolling was performed to obtain an intermediate product plate for melt treatment. Under the conditions shown in Table 2 and Table 3, each intermediate product plate was subjected to melt treatment, intermediate cold rolling, aging treatment, final cold rolling, shape correction with a tension temper, and low-temperature annealing. In some comparative examples (No. 34), 90% cold rolling was performed on the face-cut sheet material after hot rolling, and this was subjected to solution treatment as an intermediate product sheet material, and the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| longitudinal tensile yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com