Medium-/high-carbon steel sheet and method for manufacturing same

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of gap growth/connection deep drawing, etc., and achieve excellent deep drawing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

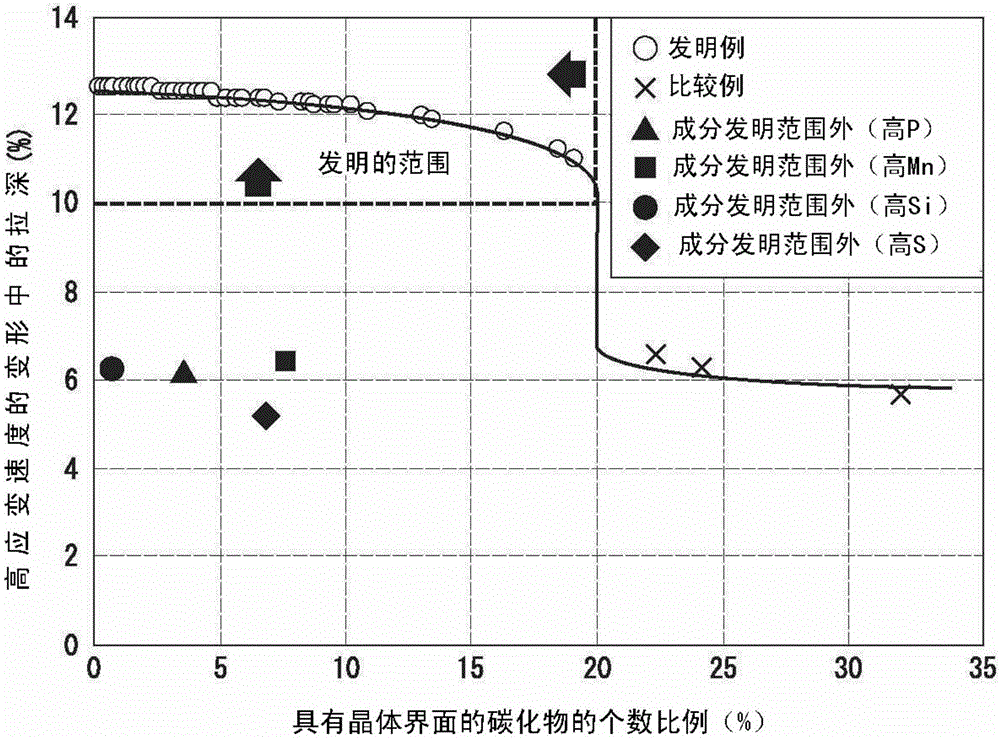

[0130]Next, the effects of the present invention will be described through examples.

[0131] The level of the examples is an example of the execution conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to the examples of the conditions. The present invention can employ various conditions as long as the purpose of the present invention is achieved without departing from the gist of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com