Automobile panel steel and preparation method thereof

A panel and automobile technology, applied in the field of automobile manufacturing materials, can solve the problems of material deep drawing performance degradation, etc., and achieve the effect of excellent deep drawing performance and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

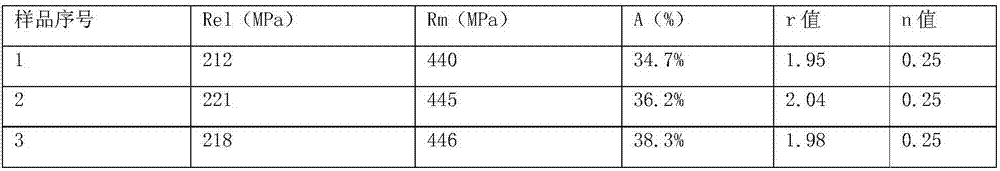

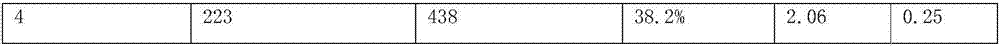

Examples

Embodiment 1

[0019] A steel for automobile panels, its composition and weight percentage content are: C: 0.002%; Si: 0.03%; Mn: 0.24%; P: 0.005%; Ti: 0.03%; Al: 0.015%; S: 0.006% ; N: 0.003%; Nb: 0.025%; Ce: 0.01%; Nd: 0.008%; the rest is Fe and unavoidable impurities.

[0020] A method for preparing steel for automobile panels, comprising the following steps:

[0021] (1) The composition and weight percentage of molten steel are: C: 0.002%; Si: 0.03%; Mn: 0.24%; P: 0.005%; Ti: 0.03%; Al: 0.015%; S: 0.006% ; N: 0.003%; Nb: 0.025%; Ce: 0.01%; Nd: 0.008%; the rest is molten steel with Fe and unavoidable impurities; the smelting process adopts RH-OB deep decarburization, in which Ce and Nd alloy elements are in Add after decarburization, and use argon gas to blow softly on the ladle for 20 minutes after adding Ce and Nd alloy elements; the tapping temperature of RH-OB is controlled at 1590 ° C ~ 1600 ° C to provide a temperature drop margin for soft blowing.

[0022] (2) Continuous casting:...

Embodiment 2

[0031] A steel for automobile panel, its composition and weight percentage content are: C: 0.002%; Si: 0.04%; Mn: 0.28%; P: 0.005%; Ti: 0.04%; Al: 0.020%; S: 0.006% ; N: 0.003%; Nb: 0.03%; Ce: 0.012%; Nd: 0.01%; the rest is Fe and unavoidable impurities.

[0032] A method for preparing steel for automobile panels, comprising the following steps:

[0033] (1) The composition and weight percentage of molten steel are: C: 0.002%; Si: 0.04%; Mn: 0.28%; P: 0.005%; Ti: 0.04%; Al: 0.020%; S: 0.006% ; N: 0.003%; Nb: 0.03%; Ce: 0.012%; Nd: 0.01%; the rest is Fe and unavoidable impurities. The smelting process adopts the RH-OB method for deep decarburization, in which Ce and Nd alloying elements are added after decarburization, and after the addition of Ce and Nd alloying elements, argon is used to blow the ladle softly for 20 minutes; the tapping temperature of RH-OB is controlled at 1590 ℃~1600℃, provide temperature drop allowance for soft blowing.

[0034] (2) Continuous casting: ...

Embodiment 3

[0042] A steel for automobile panel, its composition and weight percentage content are: C: 0.002%; Si: 0.05%; Mn: 0.30%; P: 0.005%; Ti: 0.05%; Al: 0.030%; S: 0.006% ; N: 0.003%; Nb: 0.035%; Ce: 0.015%; Nd: 0.012%; the rest is Fe and unavoidable impurities.

[0043] A method for preparing steel for automobile panels, comprising the following steps:

[0044] (1) The composition and weight percentage of molten steel are: C: 0.002%; Si: 0.05%; Mn: 0.30%; P: 0.005%; Ti: 0.05%; Al: 0.030%; S: 0.006% ; N: 0.003%; Nb: 0.035%; Ce: 0.015%; Nd: 0.012%; the rest is Fe and unavoidable impurities. The smelting process adopts the RH-OB method for deep decarburization, in which Ce and Nd alloying elements are added after decarburization, and after the addition of Ce and Nd alloying elements, argon is used to blow the ladle softly for 20 minutes; the tapping temperature of RH-OB is controlled at 1590 ℃~1600℃, provide temperature drop allowance for soft blowing.

[0045] (2) Continuous casting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com