Abrasion resistant steel plate having low-temperature toughness, and manufacturing method therefor

A technology of low temperature toughness and manufacturing method, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of low temperature toughness reduction and crack generation, and achieve the effect of excellent low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

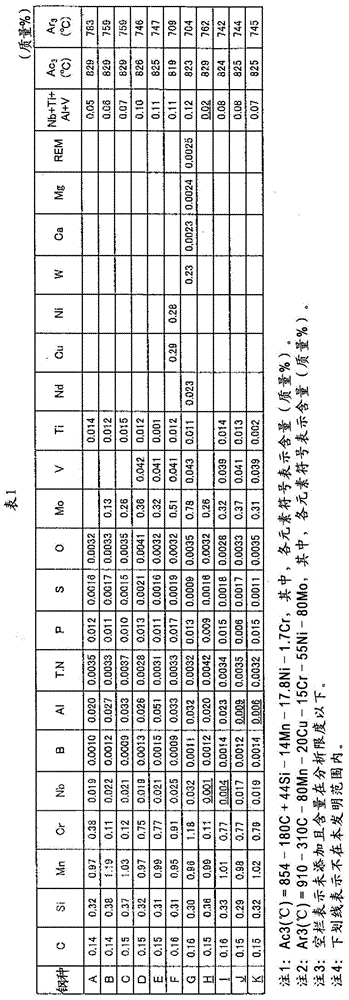

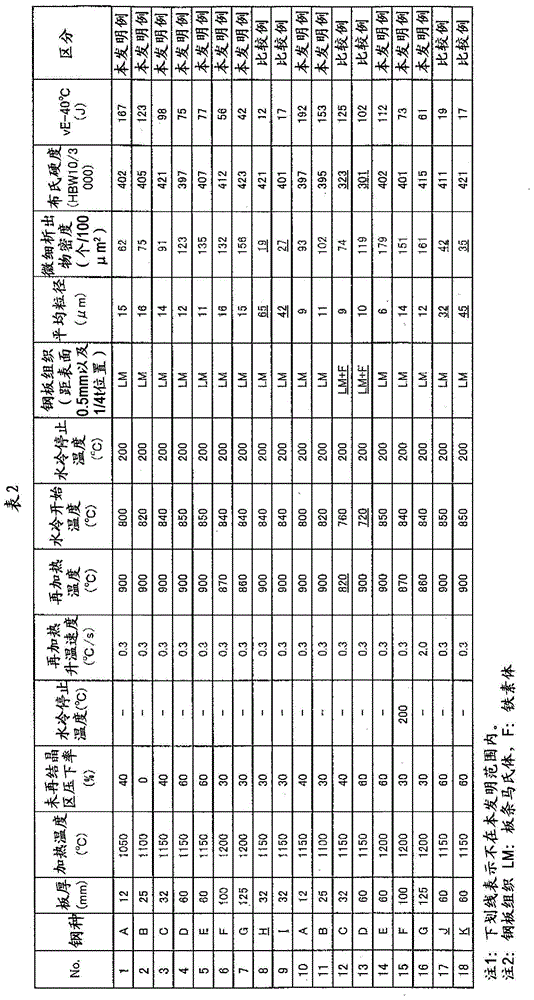

[0102] Steels A to K having the chemical compositions shown in Table 1 were melted and cast into slabs, and thick steel plates were produced under the conditions shown in Table 2. The temperature measurement of the plate was implemented with a thermocouple inserted into the central portion of the plate thickness.

[0103] Table 2 shows the structure of the steel sheet, the average grain size of crystal grains surrounded by high-angle grain boundaries with a misorientation of 15° or more, the density of fine precipitates with a diameter of 50 nm or less, the Brinell hardness of the obtained steel sheet, and the Charpy hardness at -40°C. absorb energy.

[0104] Collect samples of cross-sections perpendicular to the rolling direction, grind the cross-sections into a mirror surface, and then corrode them with a nitric acid-methanol solution. Observe the parts 0.5mm away from the surface of the steel plate and the parts 1 / 4 of the plate thickness through an optical microscope at 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com