Method for manufacturing ultra-hard composite blade

A composite blade and manufacturing method technology, applied in the direction of manufacturing tools, accessories of toolholders, tools for lathes, etc., can solve the problems of high production cost and easy falling off of superhard tools, so as to improve strength, reduce production costs, The effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

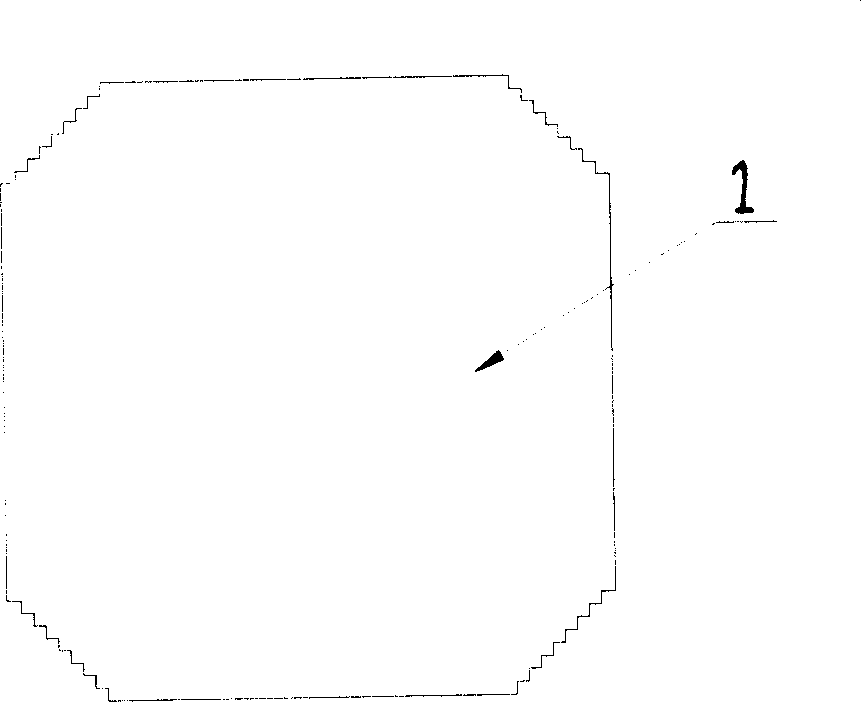

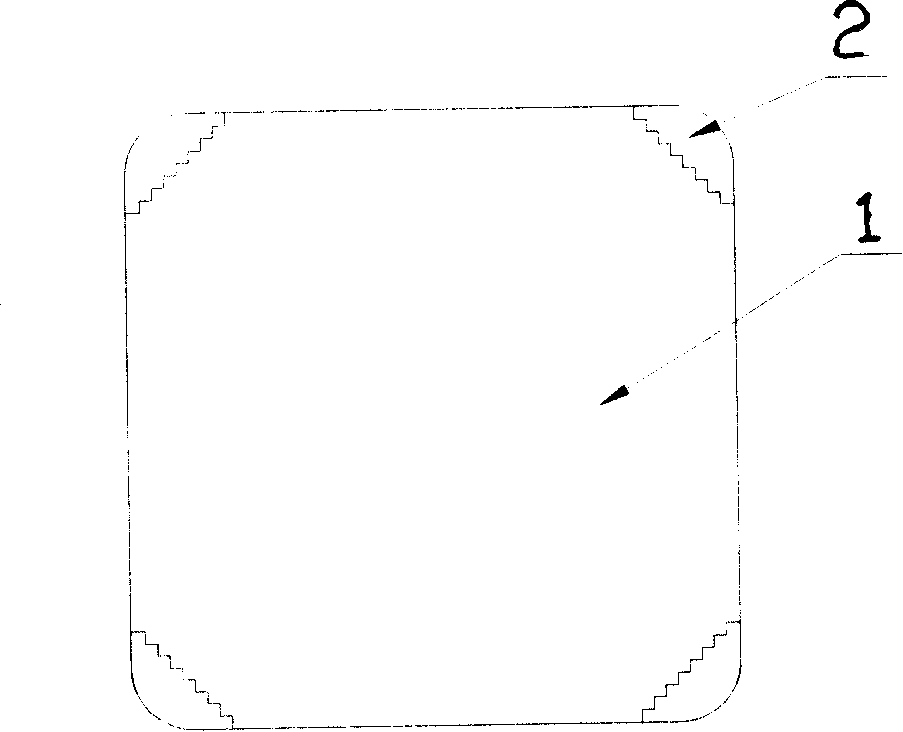

[0012] The manufacturing method of the present invention is as follows: firstly, the cemented carbide or high-speed steel plate prepared as the blade substrate 1 is divided into required specifications and shapes, then the tip part 2 is cut off and its side is processed into a curved shape, and then the formed blade is processed The matrix is placed in the corresponding sintering mold, and the superhard material and binder powder are added to the missing tip, and the superhard material and binder powder are converted into superhard polycrystalline material through high temperature and high pressure sintering, and are firmly combined with the blade matrix. Then, after grinding and sharpening, the superhard polycrystalline composite blade is made. The corresponding sintering mold is a conventional container, which is used to hold the blade matrix, superhard material and binder powder.

Embodiment 2

[0014] The manufacturing method of the present invention is as follows: firstly, the cemented carbide or high-speed steel plate prepared as the base of the blade is divided into required specifications and shapes, then the tip of the knife is cut off and its side is processed into a curved shape, and then the formed blade base is placed In the corresponding sintering mold, superhard material and binder powder are added to the missing blade tip, and the superhard material and binder powder are converted into superhard polycrystalline material through high-temperature and high-pressure sintering, which is firmly combined with the blade matrix, and then After conventional processes such as grinding and sharpening, it is made into a superhard polycrystalline composite blade.

[0015] The curved shape of the blade base body 1 after cutting off the knife tip part 2 is arc-shaped or zigzag-shaped or a convex-concave curved surface.

Embodiment 3

[0017] The manufacturing method of the present invention is as follows: firstly, the cemented carbide or high-speed steel plate prepared as the base of the blade is divided into required specifications and shapes, then the tip of the knife is cut off and its side is processed into a curved shape, and then the formed blade base is placed In the corresponding sintering mold, superhard material and binder powder are added to the missing blade tip, and the superhard material and binder powder are converted into superhard polycrystalline material through high-temperature and high-pressure sintering, which is firmly combined with the blade matrix, and then After grinding and sharpening, it is made into a superhard polycrystalline composite blade.

[0018] The superhard polycrystalline material is composed of artificial diamond or cubic boron nitride and a small amount of binder, the binder is selected from aluminum nitride, titanium nitride, molybdenum nitride, magnesium nitride, zir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com