Bismuth-based catalyst for electrocatalytic CO2 reduction to form formic acid and preparation method and application thereof

A catalyst and electrocatalysis technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of heavy metal material biotoxicity, difficulty in putting materials into use, environmental pollution reaction efficiency, etc., achieve large unsaturation, rich surface catalytic activity site, effect of promoting interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

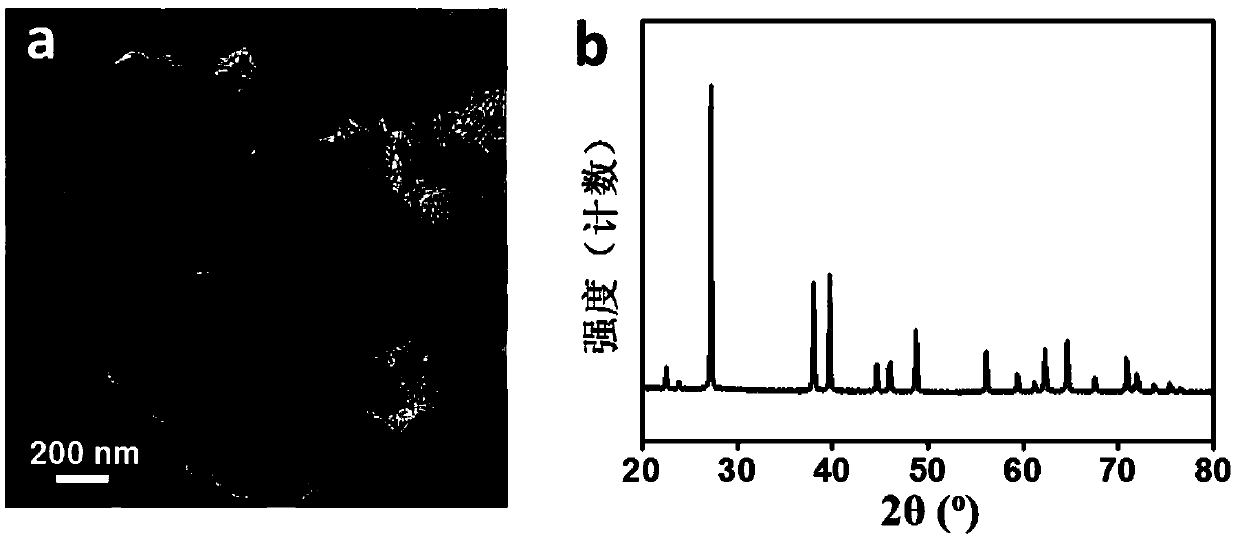

[0068] Embodiment 1: solution synthesis method prepares metal bismuth catalyst

[0069] Dissolve 100 mg of polyvinylpyrrolidone in 10 mL of ethylene glycol and 0.1 mL of deionized water. At room temperature, 75mg C 6 h 9 BiO 6 Add to the above solution, and form a uniformly dispersed solution under the assistance of ultrasound for 1 min. Subsequently, the temperature of the above reaction solution was rapidly raised to 195 o C, and maintained at this temperature for 15 min under magnetic stirring and nitrogen protection. The reaction was then quenched by adding 25 mL of ethanol and 10 mL of deionized water. After the reaction, the solid product was collected by centrifugation, washed at least three times with absolute ethanol and deionized water, and vacuum freeze-dried to obtain a solid sample of bismuth oxide nanotubes. Finally, bismuth oxide nanotubes were placed in air at 300 o Calcined at C for 1 h to remove possible residual organic matter on the surface to obtain...

Embodiment 2

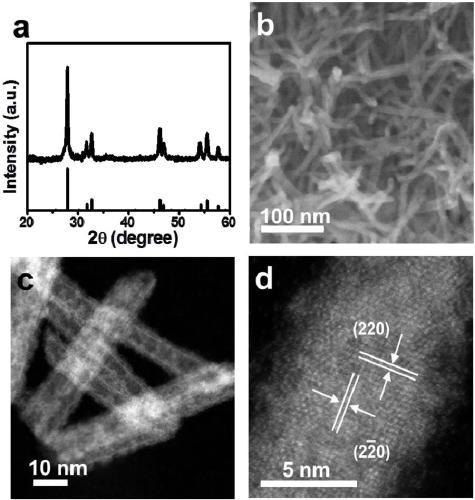

[0076] Example 2: Preparation of two-dimensional bismuth nanosheets by liquid phase exfoliation

[0077] Weighed 800 mg of bismuth powder and added it to 80 mL of N-methylpyrrolidone (NMP) to obtain a mixed solution. The probe was ultrasonicated for 4 h at a power of 900 W in a sealed condition, and the temperature was kept at 5 during the whole probe ultrasonication process. o c. Immediately after the stripping was completed, the stripping solution was transferred to three centrifuge tubes (the volume of each tube was about 27 mL), and centrifuged at 1500 rpm for 2 h respectively. h, Vacuum freeze-drying to obtain two-dimensional bismuth nanosheets.

[0078] The morphology in the SEM photo of the obtained bismuth nanosheets is an irregular sheet structure. Further use of TEM can be observed: After the exfoliation, a small amount of smaller-sized bismuth nanoparticles were simultaneously generated, with a particle size of about 10 nm. AFM characterization test results show...

Embodiment 3

[0081] Embodiment 3: Electrospinning technology prepares Bi 2 o 3 Nanofibers

[0082] Weigh 1 gram of polyacrylonitrile (PAN) powder and dissolve it in N,N-dimethylformamide solution to make a solution with a mass concentration of 10 wt%, and then add 0.1g BiCl 3 Slowly add in the above solution, and keep stirring until the solution is evenly mixed to obtain a precursor solution containing bismuth salt and polyacrylonitrile polymer (Bi 3+ = 0.5 mol / L). Transfer the prepared precursor solution to a 10 mL syringe, and fix the syringe on the micropump injector. The needle of the syringe is connected to the positive pole of the high-voltage direct current power supply, and the collecting plate covered with aluminum foil is connected to the negative pole of the high-voltage direct current power supply. Control the injection speed to 1 mL / h, and set the positive pressure to 15 kV. Composite nanofibers of bismuth salt and polyacrylonitrile can be collected by using electrospinni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com