A step-by-step phosphorus doping method for high-efficiency and low-cost crystalline silicon batteries

A low-cost technology for crystalline silicon cells, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficult to achieve control accuracy of high-efficiency crystalline silicon cells, and achieve high open circuit voltage, low recombination current, and low doping concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

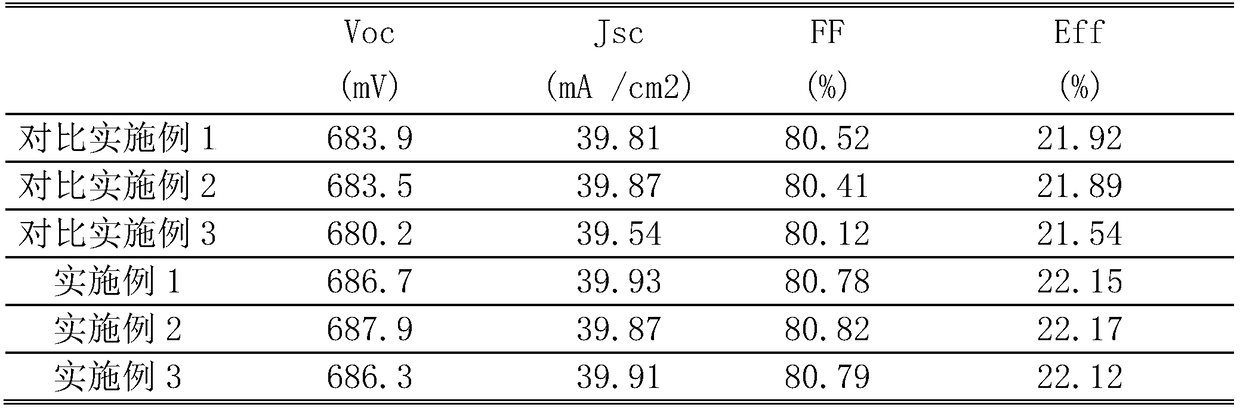

Embodiment 1

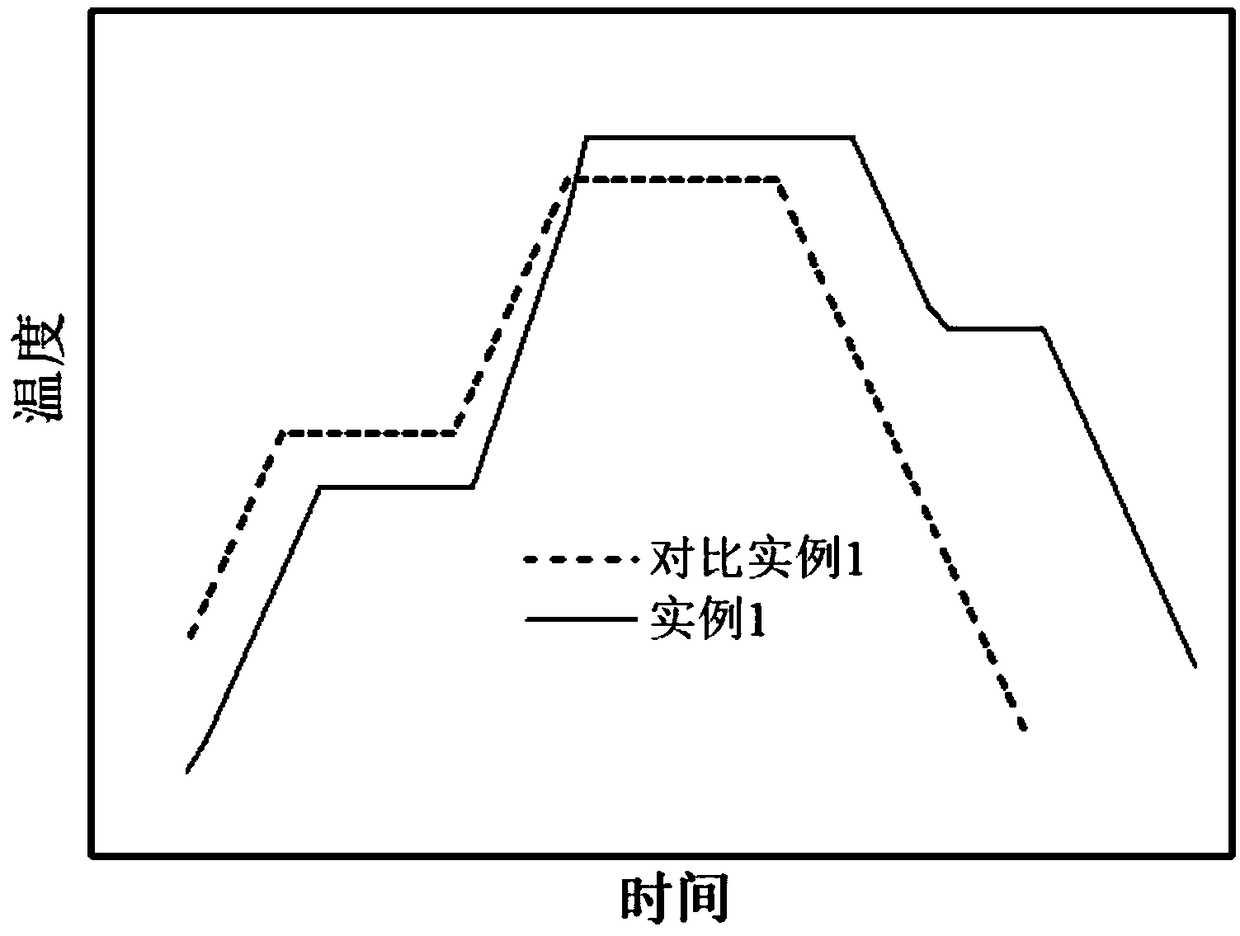

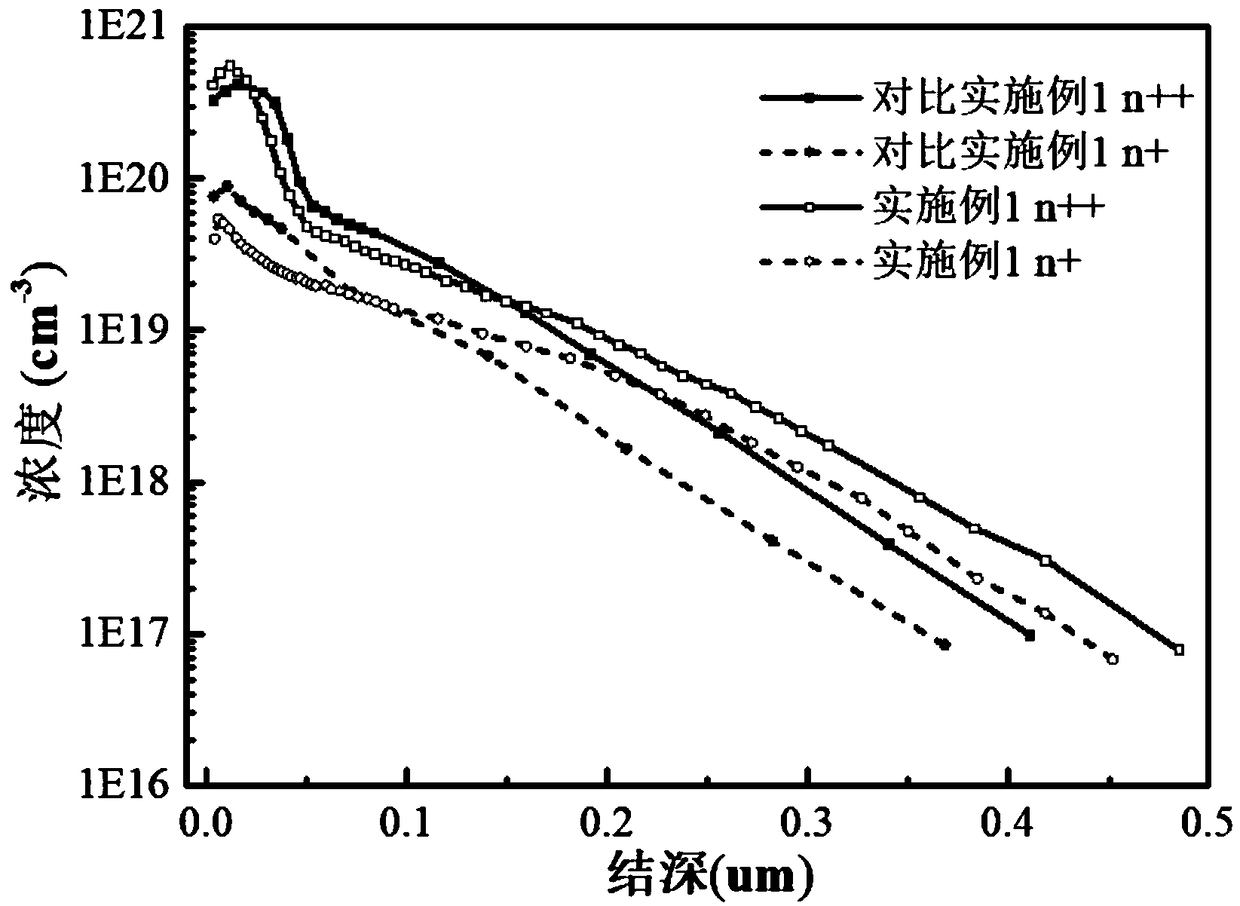

[0027] The primary depletion-type phosphorus diffusion of high-efficiency and low-cost crystalline silicon cells is combined with the secondary high-concentration shallow layer diffusion and back-etching phosphorus doping methods, and the following steps are carried out:

[0028] Step 1, the first low-temperature deposition, the temperature is controlled at 785°C, the nitrogen flow rate is 13slm, the oxygen flow rate is 250sccm, the phosphorus oxychloride flow rate is 500sccm, and the deposition is 5min;

[0029] Step 2. Keep the nitrogen flow rate at 13slm, the oxygen flow rate at 1000sccm, stop the phosphorus oxychloride flow rate, raise the temperature to 860°C at a heating rate of 10°C / min, and maintain the first push for 40min to form a low surface concentration layer n+; surface concentration 5.43×10 19 / cm 3 ;

[0030] Step 3. Keep the nitrogen flow rate at 13slm, stop the oxygen flow rate, and cool down to 830°C at a cooling rate of 10°C / min. After the second depositio...

Embodiment 2

[0036] Step 1, the first low-temperature deposition, the temperature is controlled at 760°C, the nitrogen flow rate is 11slm, the oxygen flow rate is 200sccm, the phosphorus oxychloride flow rate is 400sccm, and the deposition is 10min;

[0037] Step 2. Keep the nitrogen flow rate at 11slm, the oxygen flow rate at 800sccm, stop the phosphorus oxychloride flow rate, raise the temperature to 900°C at a heating rate of 10°C / min, and maintain the first advance for 45min to form a low surface concentration layer n+;

[0038] Step 3. Keep the nitrogen flow rate at 11slm, stop the oxygen flow rate, and cool down to 820°C at a cooling rate of 10°C / min. After the second deposition, the nitrogen flow rate is controlled at 11slm, the oxygen flow rate is controlled at 300sccm, and the phosphorus oxychloride flow rate is Control at 600sccm, deposit for 25min;

[0039] Step 4. Keep the nitrogen flow at 11slm, the oxygen flow at 850sccm, stop the flow of phosphorus oxychloride, maintain the ...

Embodiment 3

[0044] Step 1, the first low-temperature deposition, the temperature is controlled at 800°C, the nitrogen flow rate is 15slm, the oxygen flow rate is 280sccm, the phosphorus oxychloride flow rate is 560sccm, and the deposition is 3min;

[0045] Step 2. Keep the nitrogen flow rate at 15slm, the oxygen flow rate at 1100sccm, stop the phosphorus oxychloride flow rate, raise the temperature to 850°C at a heating rate of 10°C / min, and maintain the first advance for 30min to form a low surface concentration layer n+;

[0046] Step 3. Keep the nitrogen flow at 15slm, stop the oxygen flow, and cool down to 810°C at a cooling rate of 10°C / min. After the second deposition, control the nitrogen flow at 15slm, the oxygen flow at 450sccm, and the phosphorus oxychloride flow rate Control at 850sccm, deposit for 15 minutes;

[0047] Step 4. Keep the nitrogen flow at 15slm, the oxygen flow at 1150sccm, stop the flow of phosphorus oxychloride, maintain the temperature at 810°C, and carry out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com