Diffusion process of silicon-wafer laser doping SE

A laser doping and diffusion process technology, used in photovoltaic power generation, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of poor ohmic contact of silicon wafers, reduced cell efficiency, and poor ohmic contact, and achieves a solution to ohmic contact problems. bad contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

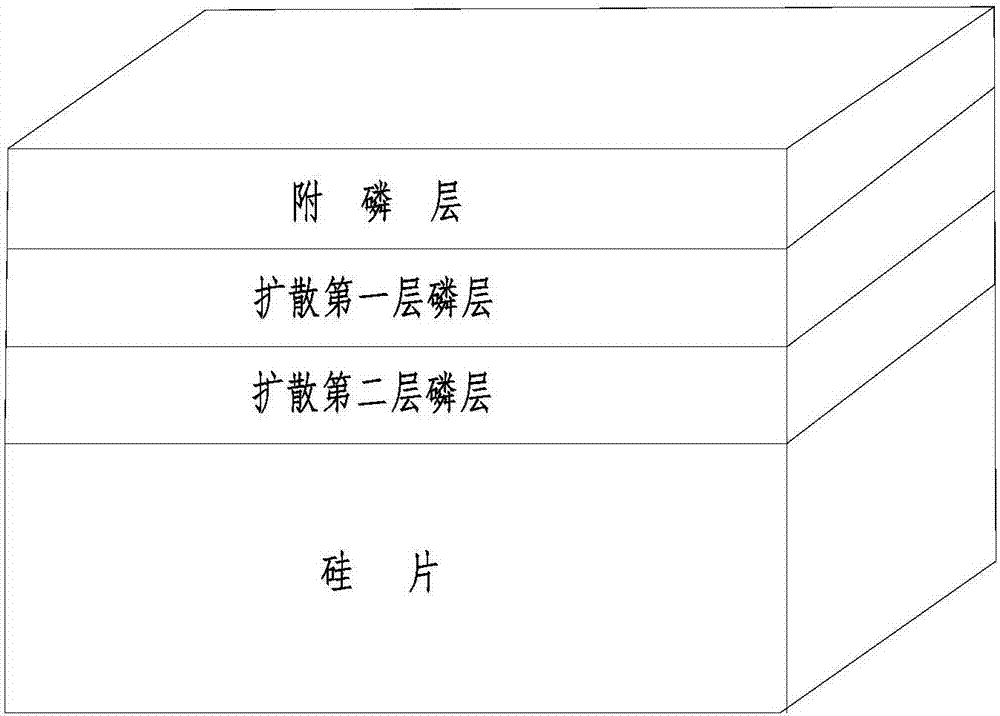

[0017] A silicon wafer laser-doped SE diffusion process, the preparation process of the silicon wafer: including sequentially cleaning the silicon wafer, diffusion, laser doping, phosphorus washing, back passivation, front coating of the silicon wafer, and backside of the silicon wafer Coating, laser drilling and screen printing.

[0018] Wherein the diffusion process has the following steps:

[0019] 1. Put the cleaned silicon wafer on the quartz boat and push it into the diffusion furnace, and the temperature in the furnace rises to 770°C;

[0020] 2. Perform pre-oxidation pretreatment on the surface of the silicon wafer in the diffusion furnace, and the treatment time is 10 minutes;

[0021] 3. Introduce nitrogen carrying POCl3 into the diffusion furnace to deposit the first layer of phosphorus source. The deposition time is 10 minutes, and the temperature in the furnace is raised to 790°C;

[0022] 4. Stop feeding the nitrogen gas carrying POCl3, and raise the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com