P diffusion method of silicon wafer and preparation method of solar cell

A diffusion method and technology of silicon wafers, which are applied in circuits, electrical components, and final product manufacturing, etc., can solve problems such as unfavorable battery conversion efficiency and fluctuation, and achieve the effects of good economic benefits, improved conversion efficiency, and improved uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The present invention also provides a method for preparing a solar cell, comprising the following steps:

[0087] Etching the back side of the silicon wafer containing the PN junction prepared by the preparation method described in the above technical scheme;

[0088] Depositing an anti-reflection film on the front side of the etched silicon wafer;

[0089] Print silver paste on the front side of the silicon wafer with the anti-reflection film deposited as the positive electrode, print aluminum paste on the back of the silicon wafer with the anti-reflection film deposited as the back electric field, and print the aluminum paste on the back of the silicon wafer with the anti-reflection film deposited Printing silver-aluminum paste as the back electrode;

[0090] The silicon wafer printed with the positive electrode, the back electric field and the back electrode is sintered to obtain a solar cell.

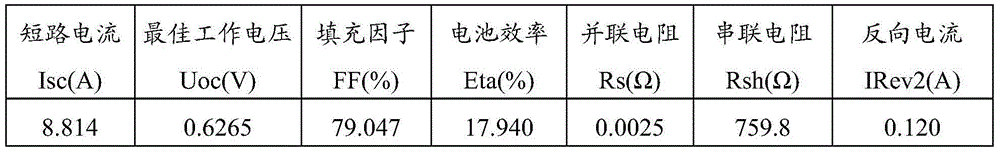

[0091] According to the P diffusion method described in the above tech...

Embodiment 1

[0098] Select P-type polysilicon wafers of 156cm×156cm, and use acid solution for texturing and cleaning in the production line to form a textured surface;

[0099] P diffusion in a tubular diffusion furnace using a liquid source of phosphorus oxychloride:

[0100] Low-temperature boat feeding: put the textured polysilicon wafer into the tubular diffusion furnace, set the temperature of the furnace tube at 780°C, and feed 8L / min of N into the tubular diffusion furnace. 2 ;

[0101] The first temperature rise: control N after entering the boat 2 The flow rate is 6L / min, and the furnace tube is rapidly heated to 810°C at a heating rate of 12°C / min;

[0102] The first deposition: feed 7.5L / min of N into the tubular diffusion furnace 2 , 600mL / min O 2 and 900mL / min of N 2 -POCl 3 , N 2 -POCl 3 Medium N 2 and POCl 3 The volume ratio is 10:1, the furnace tube temperature is controlled at 810°C, and the deposition time is 8 minutes;

[0103] The first propulsion: feed 9L / m...

Embodiment 2

[0122] Select P-type polysilicon wafers of 156cm×156cm, and use acid solution for texturing and cleaning in the production line to form a textured surface;

[0123] P diffusion in a tubular diffusion furnace using a liquid source of phosphorus oxychloride:

[0124] Low-temperature boat feeding: put the textured polysilicon wafer into the tubular diffusion furnace, set the temperature of the furnace tube at 780°C, and feed 8L / min of N into the tubular diffusion furnace. 2 ;

[0125] The first temperature rise: control N after entering the boat 2 The flow rate is 6L / min, and the furnace tube is rapidly heated to 810°C at a heating rate of 12°C / min;

[0126] The first deposition: feed 7.5L / min of N into the tubular diffusion furnace 2 , 600mL / min O 2 and 950mL / min of N 2 -POCl 3 , N 2 -POCl 3 Medium N 2 and POCl 3 The volume ratio is 10:1, the furnace tube temperature is controlled at 810°C, and the deposition time is 10 minutes;

[0127] The first propulsion: feed 9L / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com