Two-end gas intake device for phosphorous diffusion furnace tube

A technology of air intake device and phosphorus diffusion, which is applied in the field of diffusion furnace, can solve the problems of poor uniformity of the resistance plate, and achieve the effect of improving the uniformity of square resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

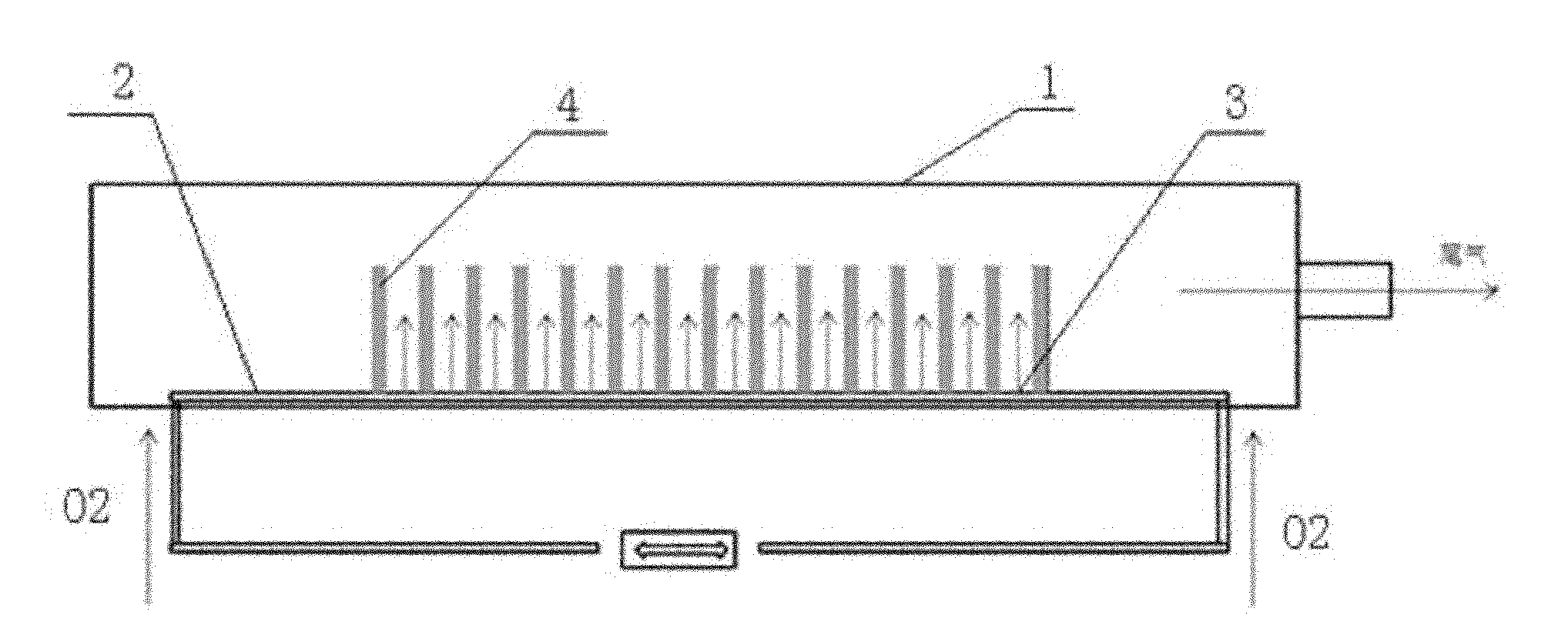

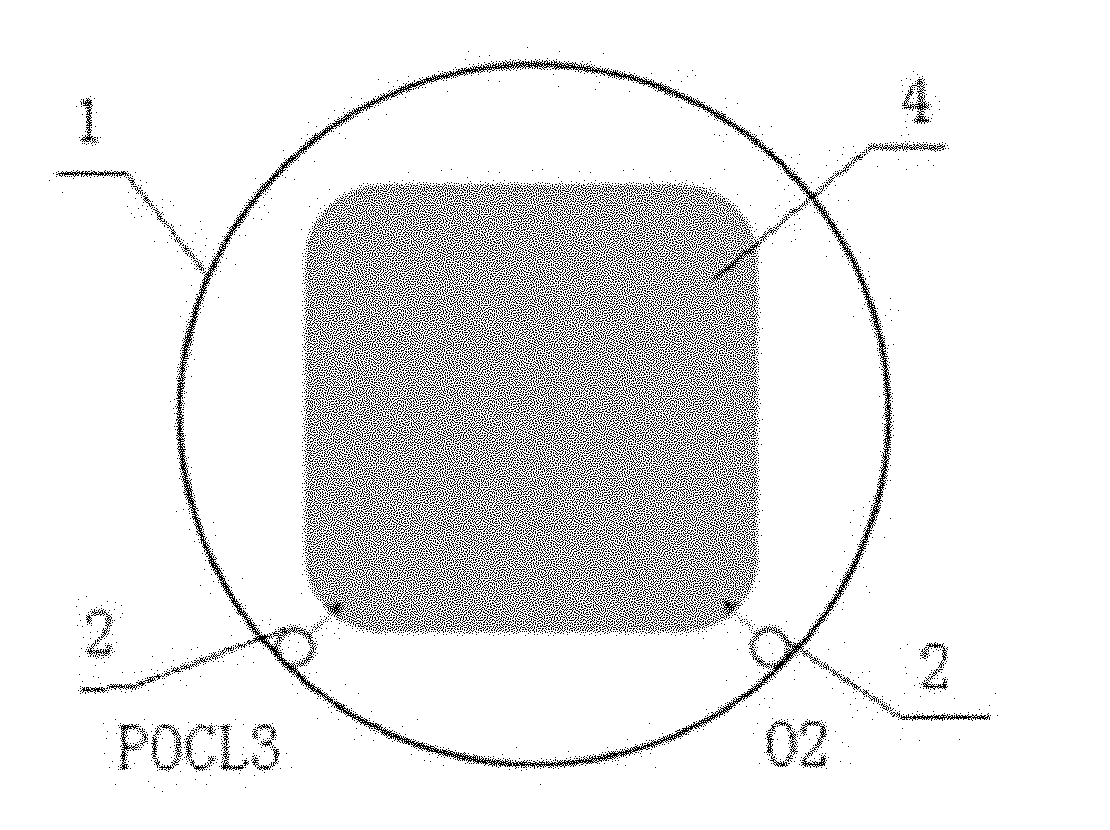

[0013] Such as figure 1 As shown, a kind of air inlet device at both ends of the phosphorus diffusion furnace tube includes two air inlet pipes 2 extending in the furnace pipe 1, the two ends of each air inlet pipe 2 are connected to the gas source, and the two ends of each air inlet pipe 2 The same kind of reaction gas is fed in, and the intake ratio at both ends of each intake pipe is adjusted through the valve. There are evenly distributed air outlet holes 3 on the air inlet pipe 2, and the outlet direction of the air outlet holes 3 is parallel to the surface of the silicon wafer 4. The root inlet pipe 2 is fed with different reaction gases respectively to prevent the gases from reacting in advance. The air outlet directions of the air outlet holes 3 on the two air inlet pipes 2 are perpendicular to each other. The extending directions of the two inlet pipes 2 are parallel to the axial direction of the furnace tube 1, and are respectively located in the direction of 15:30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com