Preparation method of carbon nanotube/nitrogen-doped modified fiber body composite material

A technology of carbon nanotubes and modified fibers, which is applied in the field of materials, can solve problems such as difficulty in obtaining technological breakthroughs, high prices, and long preparation cycles, so as to improve interfacial bonding force and dispersion performance, realize large-scale industrial production, The effect of excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: Soak the aluminum silicate fiber cloth in the polyvinylidene fluoride mixed solution at a temperature of 60°C for hot filling treatment for 1 hour, then add the cinnamic amide mixed solution dropwise to adjust the pH of the solution to 8, and obtain a liquid-solid mass ratio of 2:1 mixed precursor solution A;

[0033] Among them, the aluminum silicate fiber cloth is a combined needle felt body, which is composed of 40% chopped strand mat, 20% roving cloth and 40% chopped yarn according to the mass ratio, and the composition contains 50% by mass Aluminum silicate, 20% zirconia, 20% titanium oxide and 10% beryllium oxide;

[0034] The polyvinylidene fluoride mixed solution is composed of 55% ethylene glycol monomethyl ether, 15% polyvinylidene fluoride and 30% deionized water by volume;

[0035] The cinnamic amide mixed solution is composed of 40% cinnamic amide, 20% potassium hydroxide and 40% deionized water by mass ratio;

[0036] Step 2: Take 80g of the mixed ...

Embodiment 2

[0044] Step 1: Soak the aluminum silicate fiber cloth in the polyvinylidene fluoride mixed solution at a temperature of 70°C for hot filling treatment for 1.5 hours, then add the cinnamic amide mixed solution drop by drop to adjust the pH of the solution to 8.5, and obtain the liquid-solid mass ratio Mix Precursor A at 5:1;

[0045] Among them, the aluminum silicate fiber cloth is a combined needle felt body, which is composed of 60% chopped strand mat, 20% roving cloth and 20% chopped yarn according to the mass ratio, and the composition contains 30% by mass Aluminum silicate, 30% zirconia, 25% titanium oxide and 15% beryllium oxide;

[0046] The polyvinylidene fluoride mixed solution is composed of 50% ethylene glycol monomethyl ether, 20% polyvinylidene fluoride and 30% deionized water by volume;

[0047] The cinnamic amide mixed solution is composed of 60% cinnamic amide, 20% potassium hydroxide and 20% deionized water in a mass ratio;

[0048] Step 2: Take 100g of the m...

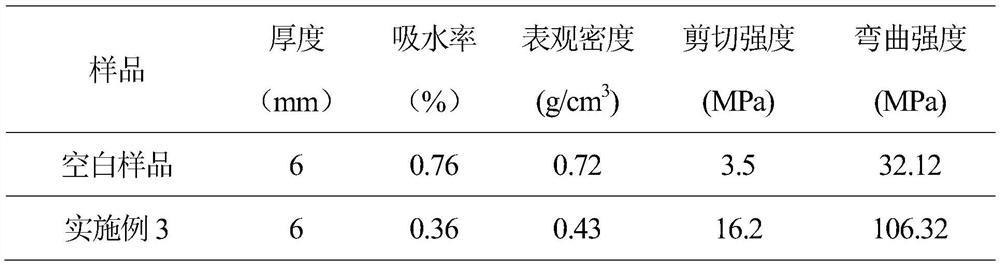

Embodiment 3

[0056] Step 1: Soak the aluminum silicate fiber cloth in the polyvinylidene fluoride mixed solution at a temperature of 80°C for hot filling treatment for 2 hours, then add the cinnamic amide mixed solution dropwise to adjust the pH of the solution to 9, and obtain a liquid-solid mass ratio of 4:1 mixed precursor solution A;

[0057] Among them, the aluminum silicate fiber cloth is a combined needle felt body, which is composed of 40% chopped strand mat, 40% roving cloth and 20% chopped yarn according to the mass ratio, and the composition contains 30% by mass Aluminum silicate, 40% zirconia, 20% titanium oxide and 10% beryllium oxide;

[0058] The polyvinylidene fluoride mixed solution is composed of 60% ethylene glycol monomethyl ether, 10% polyvinylidene fluoride and 30% deionized water by volume;

[0059] The cinnamic amide mixed solution is composed of 50% cinnamic amide, 25% potassium hydroxide and 25% deionized water by mass ratio;

[0060] Step 2: Take 90g of the mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com