Long-glass fiber reinforced polyvinyl alcohol material and preparation method thereof

A long glass fiber and polyvinyl alcohol technology, applied in the field of materials, can solve the problems of limited application market, restricting the production capacity of PVA industry, and unfavorable important role of PVA, etc., achieve excellent mechanical strength, easy to realize industrialization, excellent gas barrier and oil resistance The effect of material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

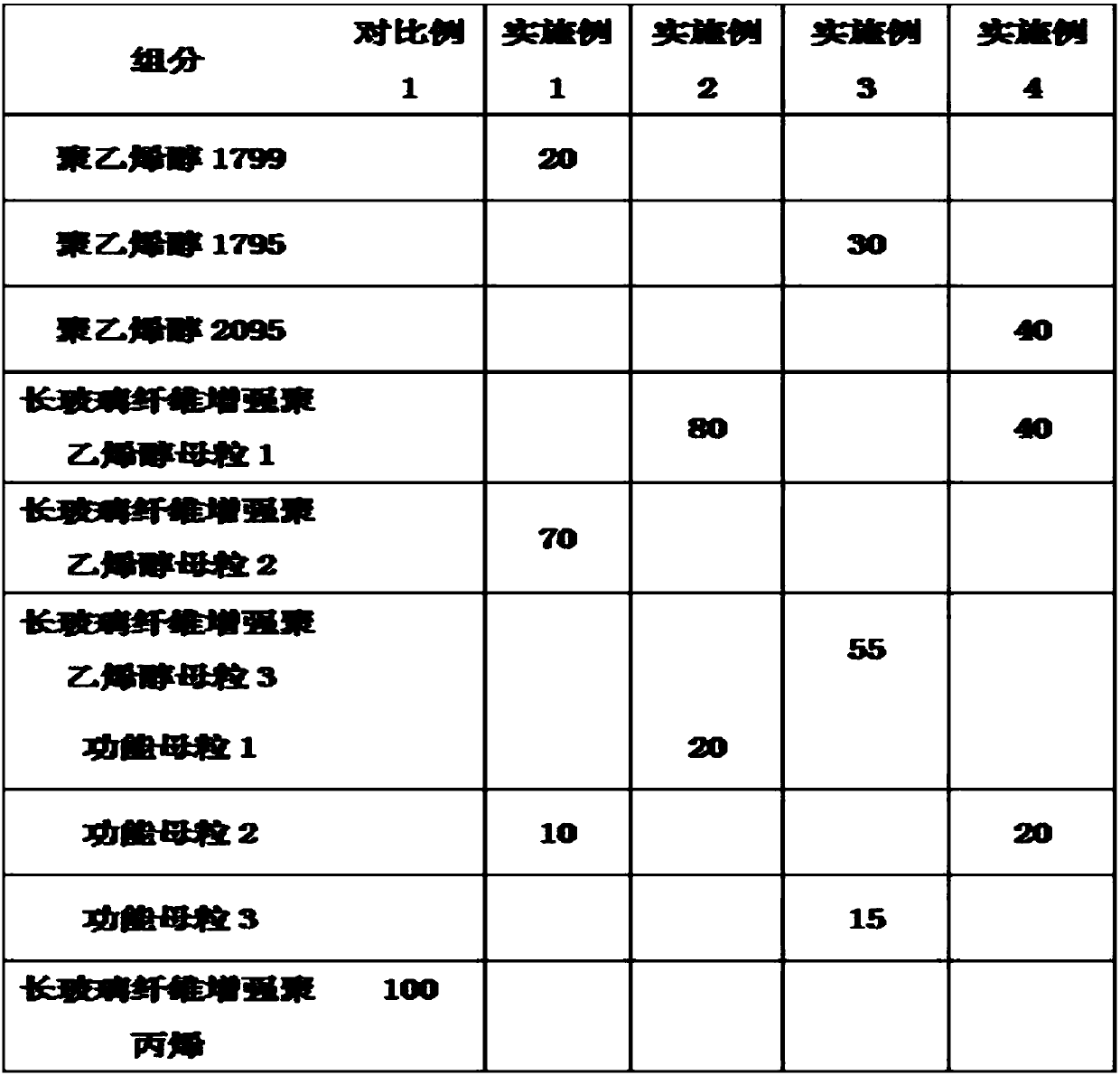

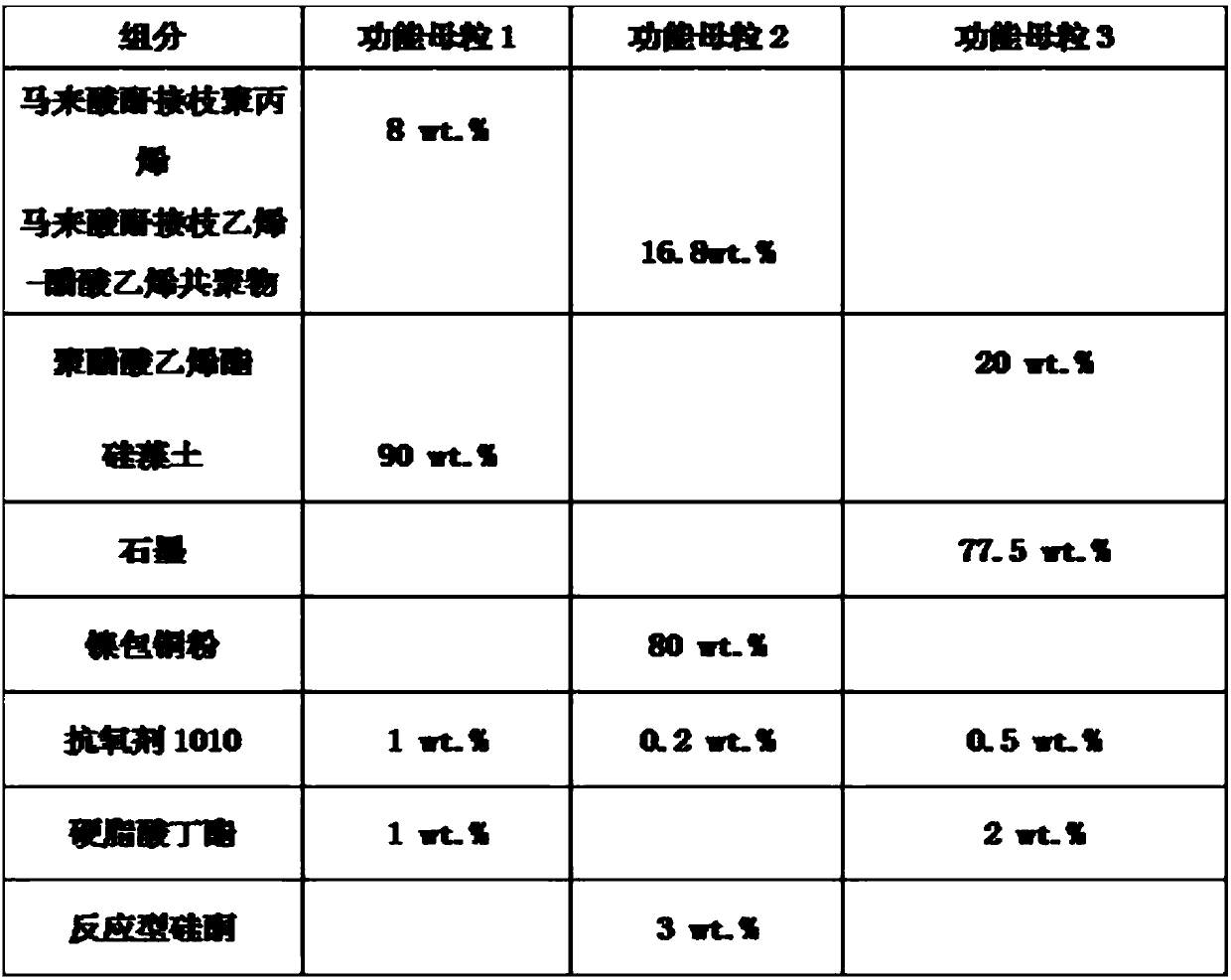

Embodiment 1

[0029] Prepare according to the following method according to the materials and components of Example 1 in the corresponding table 1-3:

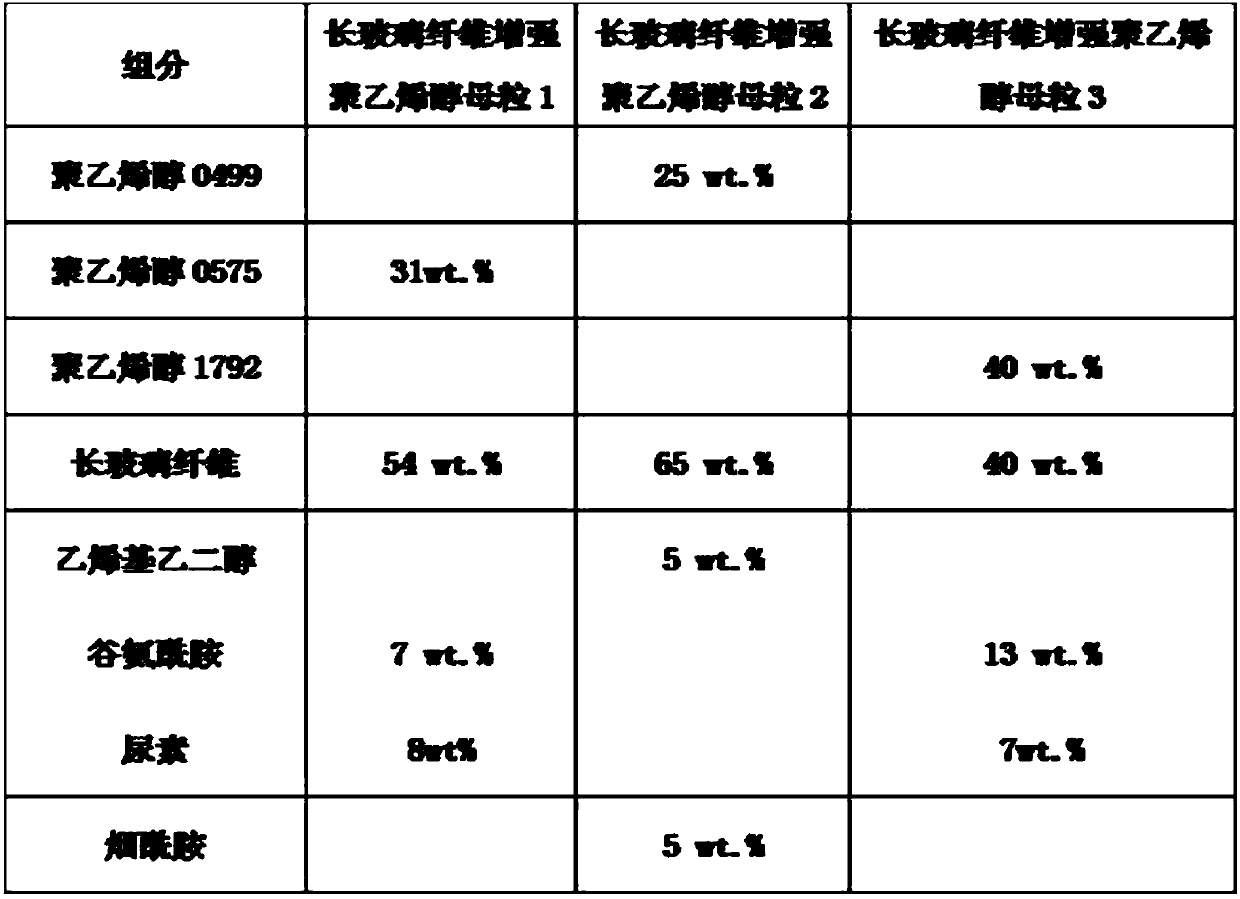

[0030] Step 1 prepares 70 parts of long glass fiber reinforced polyvinyl alcohol masterbatch: according to the material components in long glass fiber reinforced polyvinyl alcohol masterbatch (wherein polyvinyl alcohol 0499 accounts for 25wt%, long glass fiber accounts for 65wt%, vinyl ethylene glycol Alcohol accounts for 5wt%, nicotinamide accounts for 5wt%) polyvinyl alcohol 0499, flow modifier (vinyl glycol, nicotinamide) are premixed in a high-speed mixer according to parts by weight for 0.5min, and then the mixture is placed in Stand still in the reaction kettle for 0.5h; then, put the above mixture into the twin-screw extruder, extrude the polyvinyl alcohol melt into the impregnation mold connected with the head of the twin-screw extruder, and then pass the long glass fiber through the impregnation Mold, so that the long glass fiber is...

Embodiment 2

[0036] Prepare according to the following method according to the materials and components of Example 1 in the corresponding table 1-3:

[0037] Step 1 prepares 80 parts of long glass fiber reinforced polyvinyl alcohol masterbatch: according to the material components in long glass fiber reinforced polyvinyl alcohol masterbatch (wherein polyvinyl alcohol 0575 accounts for 45wt.%, long glass fiber accounts for 54wt% glutamine accounts for 1wt%) with polyvinyl alcohol 0575, flow modifier (glutamine) is premixed 5min in the high-speed mixer according to parts by weight, after the mixture is placed in the reactor and left to stand for 3h; In the screw extruder, the polyvinyl alcohol melt is extruded into the impregnation mold connected with the head of the twin-screw extruder, and then the long glass fiber is passed through the impregnation mold, so that the long glass fiber is fully impregnated by the melt, and finally cooled, Traction and pelletizing to obtain long glass fiber r...

Embodiment 3

[0042] Prepare according to the following method according to the materials and components of Example 1 in the corresponding table 1-3:

[0043] Step 1 prepares 55 parts of long glass fiber reinforced polyvinyl alcohol masterbatch: according to the material components in long glass fiber reinforced polyvinyl alcohol masterbatch (wherein polyvinyl alcohol 1792 accounts for 55wt%, long glass fiber accounts for 40wt%, glutamine accounts for 1wt%, urea accounts for 4wt%) with polyvinyl alcohol 1792, flow modifier (glutamine accounts for, urea) premixes 1min in the high-speed mixer according to parts by weight, and then puts the mixture in the reactor and stands still for 1h Then, put the above mixture into the twin-screw extruder, extrude the polyvinyl alcohol melt into the impregnation die connected with the head of the twin-screw extruder, then pass the long glass fiber through the impregnation die, so that the long glass fiber is The melt is fully impregnated, and finally coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com