Low-density, low-dielectric-constant and high-weather-resistance polypropylene material and preparation method thereof

A low dielectric constant and polypropylene material technology, applied in the field of polymer material modification, can solve the problems of low density and low dielectric constant, and achieve the effect of low density, low dielectric constant and enhanced binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

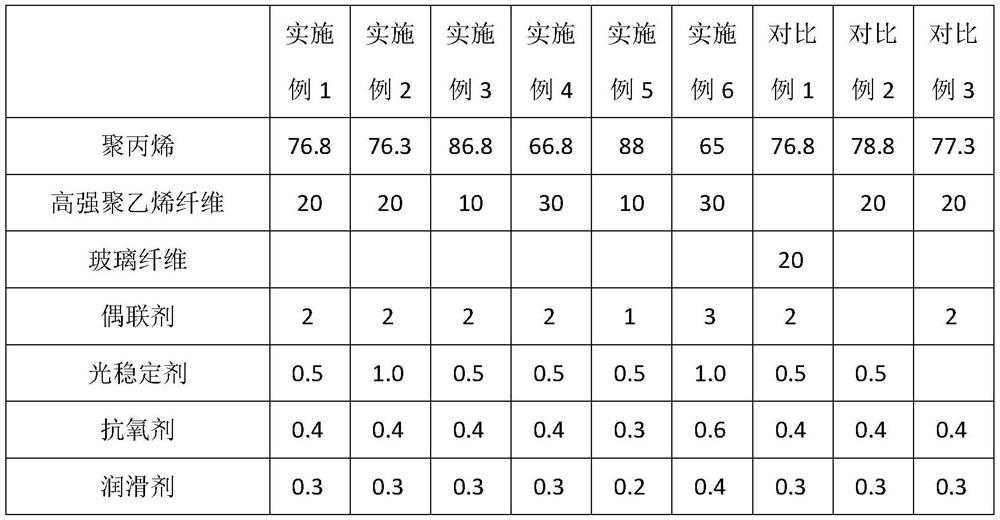

[0029] The present invention will be described in further detail below in conjunction with the embodiments. The scope of the present invention is not limited by these examples, but is set forth in the claims.

[0030] In the material formulations of the examples and comparative examples, the polypropylene used is polypropylene produced by SK Company, trade name BX3900, and its melt flow rate is 60g / 10min (test condition: 230°C×2.16kg). The high-strength polyethylene fiber is ZTX-99 produced by Hunan Zhongtai Special Equipment Co., Ltd., its fiber monofilament fineness is 2.5 denier, and its dielectric constant is 2.2. The glass fiber is an alkali-free glass fiber with a diameter of 12 microns, and its dielectric constant is 6.5. The coupling agent is silane coupling agent KH550, which is commercially available. The light stabilizer is selected from Mingzhi titanium rutile titanium dioxide MZT-R1, and its particle size is about 15nm. The antioxidant is the composition of 101...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com