A kind of glass fiber reinforced polycarbonate composite material and preparation method thereof

A technology of polycarbonate and composite materials, which is applied in the field of engineering plastics, can solve the problems of complex and time-consuming processes, low yield, and low efficiency, and achieve the effects of improving compatibility and dispersion, reducing content, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

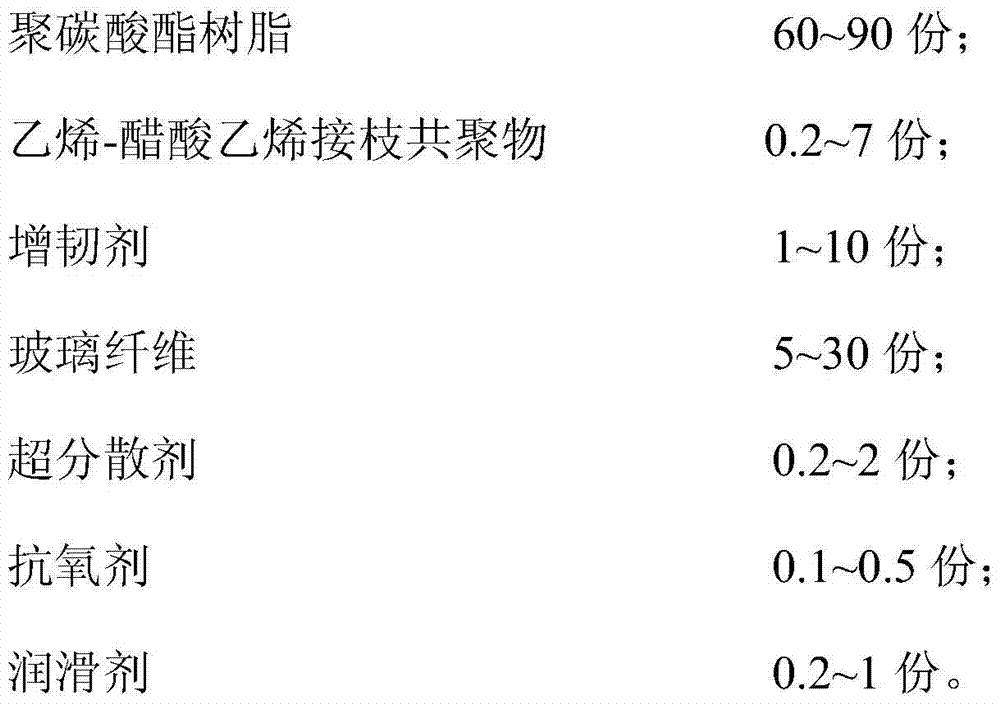

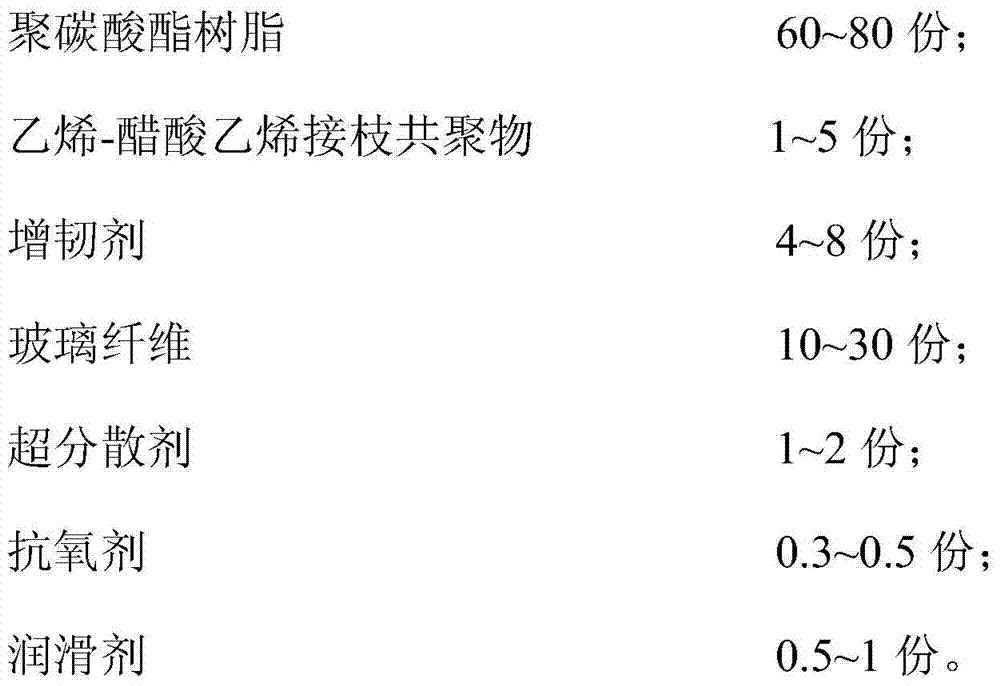

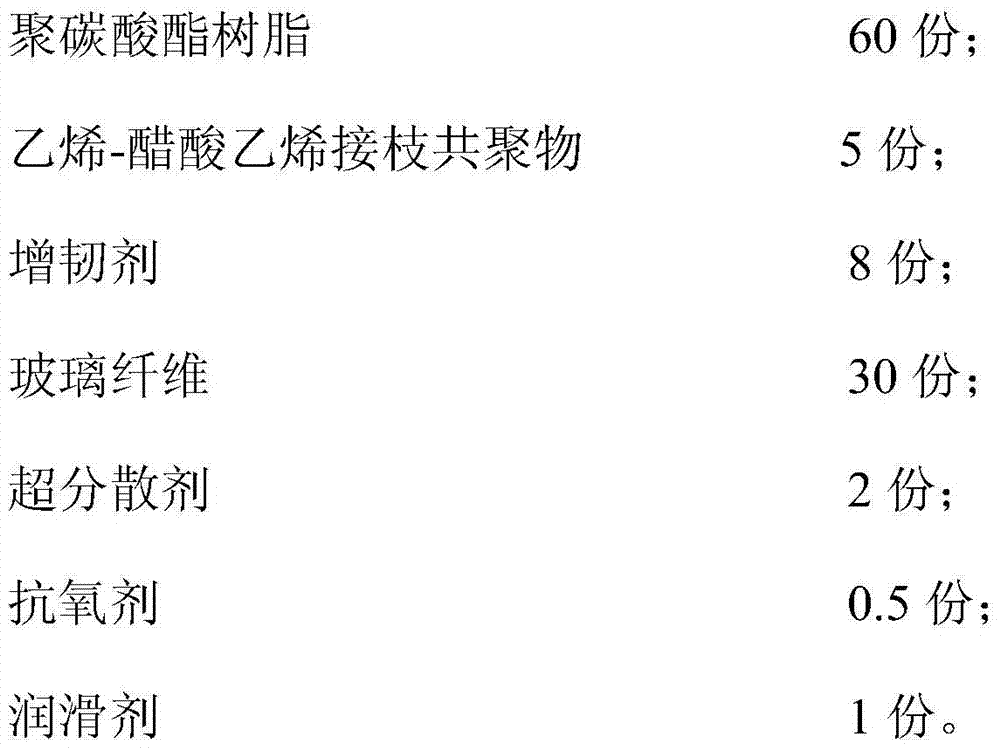

[0045] Embodiment 1: The glass fiber reinforced polycarbonate composite material of this embodiment, by mass parts, includes the following components:

[0046]

[0047] The method for preparing the above-mentioned polycarbonate composition comprises the following steps:

[0048] Reduce meshing blocks in the screw combined melting section of the twin-screw extruder, add ZME toothed screw elements in the mixing and homogenizing section, and combine the twin-screw extruder into a low-shear high-dispersion screw;

[0049] In parts by mass, mix 85 parts of polycarbonate resin, 0.5 part of ethylene-vinyl acetate graft copolymer, 2 parts of silicone toughening agent, 0.5 part of hyperdispersant, 0.1 part of antioxidant, and 0.3 part of lubricant , to prepare a mixture;

[0050] Put the above mixture into the adjusted twin-screw extruder, and put in 10 parts of glass fiber from the side feed port, heat and melt at 290°C and a speed of 400r / min to make the mixture blend into plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com