Phosphorus diffusion method for preparing silicon solar battery

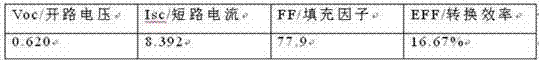

A silicon solar cell, phosphorus diffusion technology, applied in the direction of circuits, electrical components, final product manufacturing, etc., can solve the non-uniform atmosphere environment and the radial difference of the temperature field, affect the controllability of process parameters, the electrical performance of solar cells, Unable to achieve uniform diffusion state and other problems, to achieve the effect of increasing equipment tooling and process time, reducing surface minority carrier recombination rate, and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A phosphorus diffusion method for preparing a silicon solar cell, the steps comprising:

[0024] (1) Put conventional polycrystalline boron-doped P156 silicon wafers after texturing into a diffusion furnace tube with a nitrogen flow rate of 14-16 L / min and a temperature of 800 °C;

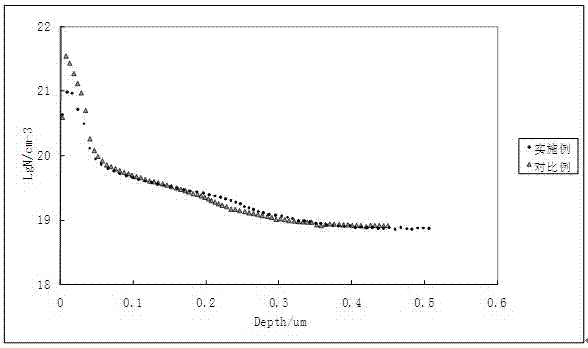

[0025] (2) Raise the temperature to about 830°C, and at the same time feed nitrogen and dry oxygen carrying phosphorus sources for constant source diffusion. The diffusion time is 15-25 minutes, and the flow rate of dry oxygen is 0.4-0.5 L / min. The phosphorus source is trichlor Oxyphosphorus, the source temperature is constant at 15~18°C, and the flow rate of the source nitrogen gas is 1.3~1.6L / min, so that the surface concentration of phosphorus impurities on the surface of the silicon wafer is 1.2e+21 cm -3 ;

[0026] (3) Keep the temperature of the furnace tube and the flow rate of dry oxygen unchanged, stop feeding the source nitrogen, and carry out aerobic limited source diffusion for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com