Emitter electrode structure capable of improving crystal silicon solar battery shortwave response

A technology of crystalline silicon solar cells and emitters, which can be used in circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as heavy doping of emitters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

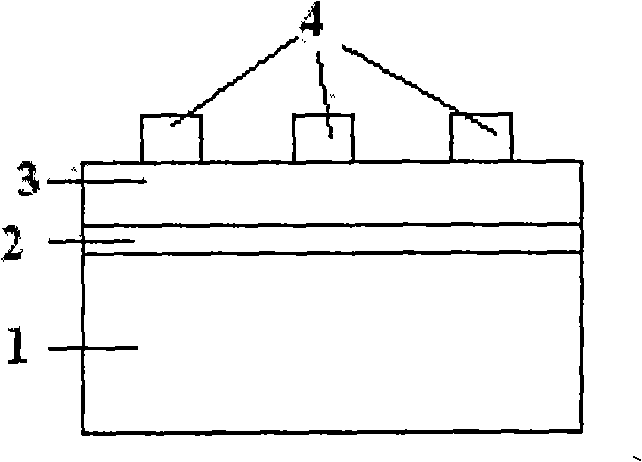

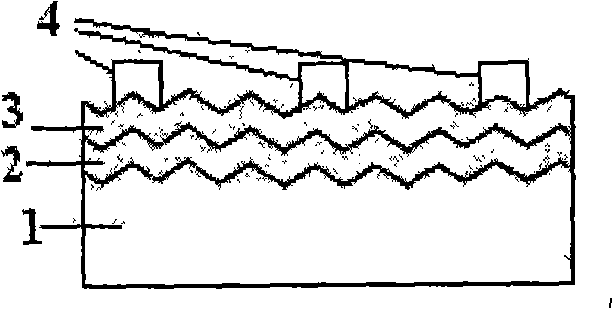

[0019] The emitter structure in this embodiment is as figure 2 As shown, the crystalline silicon substrate 1 is a p-type monocrystalline silicon substrate with a textured surface. On the crystalline silicon substrate 1 is a crystalline silicon layer 2, the crystalline silicon layer 2 is an n-type single crystal silicon layer prepared by diffusion, and the surface doping concentration is 1.0×10 19 / cm 3 , Sheet resistance 200Ω·cm. On the crystalline silicon layer 2 is a transparent conductive electrode layer 3, and the transparent conductive electrode layer 3 is an 80nm thick ITO layer prepared by magnetron sputtering. On the transparent conductive electrode layer 3 are metal grid lines 4, and the metal grid lines 4 are Ag grid lines prepared by thermal evaporation.

Embodiment 2

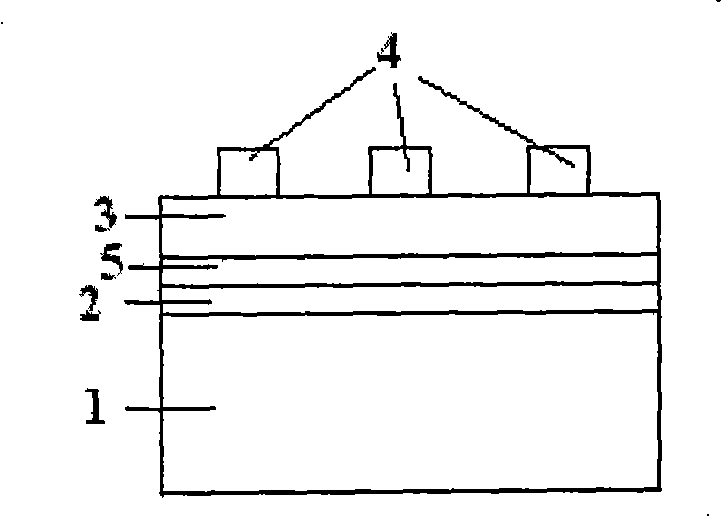

[0021] The emitter structure in this embodiment is as image 3 As shown, the crystalline silicon substrate 1 is an n-type polycrystalline silicon substrate with a flat surface. On the crystalline silicon substrate 1 is a crystalline silicon layer 2, the crystalline silicon layer 2 is a p-type crystalline silicon layer grown epitaxially, and the doping concentration is 1.0×10 20 / cm 3 , Sheet resistance 300Ω·cm. On the crystalline silicon layer 2 is an intrinsic amorphous silicon layer 5, which is prepared by PECVD with a thickness of 1 nm. On the intrinsic amorphous silicon layer 5 is a transparent conductive electrode layer 3, which is an 80nm thick ZnO·Al layer prepared by thermal evaporation. On the transparent conductive electrode layer 3 is a metal grid line 4, and the metal grid line 4 is an Al grid line prepared by magnetron sputtering.

Embodiment 3

[0023] The emitter structure in this embodiment is as Figure 4 As shown, the crystalline silicon substrate 1 is a p-type polycrystalline silicon substrate with a textured surface. On the crystalline silicon substrate 1 is a crystalline silicon layer 2, the crystalline silicon layer 2 is an n-type crystalline silicon layer prepared by diffusion, and the doping concentration is 1.0×10 20 / cm 3 , Sheet resistance 500Ω·cm. On the crystalline silicon layer 2 is an intrinsic amorphous silicon layer 5 prepared by HWCVD with a thickness of 10 nm. The transparent conductive electrode layer 3 is on the intrinsic amorphous silicon layer 5, and the transparent conductive electrode layer 3 is an 80nm thick ZnO·Al layer prepared by electron beam evaporation. On the transparent conductive electrode layer 3 is a metal grid line 4, and the metal grid line 4 is an AgAl alloy grid line prepared by electron beam evaporation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com