Technology for preparing emitting electrode without dead layer by adopting alkaline method and texturization

A preparation process and emitter technology, applied in the field of preparation process of non-dead layer emitter after alkali method, can solve the problems affecting battery efficiency, etc., achieve the effect of improving short-wave response, easy industrial production, and reducing dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

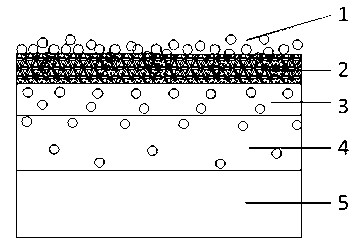

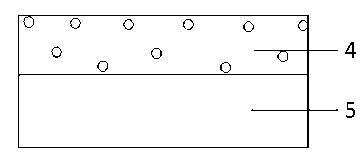

Embodiment 1

[0028] Put the P-type monocrystalline silicon wafer 5 into a NaOH solution with a temperature of 80°C and a concentration of 180g / L, soak for 20s, and remove the damaged layer on the surface of the silicon wafer 5; then put the silicon wafer 5 into a conventional diffusion furnace, Perform traditional diffusion with a diffusion time of 6 hours to prepare an emitter with a square resistance of 8 ohm / sq; use HF acid solution with a concentration of 10% to remove the silicon glass 2 containing doping sources on the surface of the silicon wafer; Put the silicon wafer 5 of the silicon glass 2 with a concentration of 5g / L and a mixed solution of IPA with a concentration of 150g / L to complete the surface texture for 1000s, and remove the dead layer emitter 3 at the same time. The square resistance of the surface of the silicon wafer 5 without the dead layer emitter 4 is 78 ohm / sq; then put it into a mixed solution of 5% HCl and 7% HF acid for cleaning for 5 minutes. Then the silicon ...

Embodiment 2

[0030] Put the P-type monocrystalline silicon wafer 5 into the NaOH solution with a temperature of 80°C and a concentration of 180g / L, soak for 20s, and remove the damaged layer on the surface of the silicon wafer 5; then put the silicon wafer 5 into a conventional diffusion furnace , carry out traditional diffusion, the diffusion time is 5.5h, and prepare an emitter with a square resistance of 10ohm / sq; use a HF acid solution with a concentration of 10% to remove the silicon glass 2 containing the dopant source on the surface of the silicon wafer; the removed Put the silicon wafer 5 of silicon glass 2 containing the dopant source into a mixed solution of NaOH with a concentration of 5g / L and IPA with a concentration of 150g / L to complete the surface texture for 940s, and remove the dead layer emitter 3 at the same time At this time, the square resistance of the surface of the silicon wafer 5 without the dead layer emitter 4 is 83 ohm / sq; then put it into a mixed solution of 5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com