P-type amorphous silicon carbon-nanoparticle silicon multi-quantum well window layer material

An amorphous silicon carbon and nanoparticle technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of decreased structural order, wide band gap, difficult high conductivity performance, decreased conductivity, etc. Response and short-circuit current density, reduced light absorption loss, enhanced effect of built-in electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

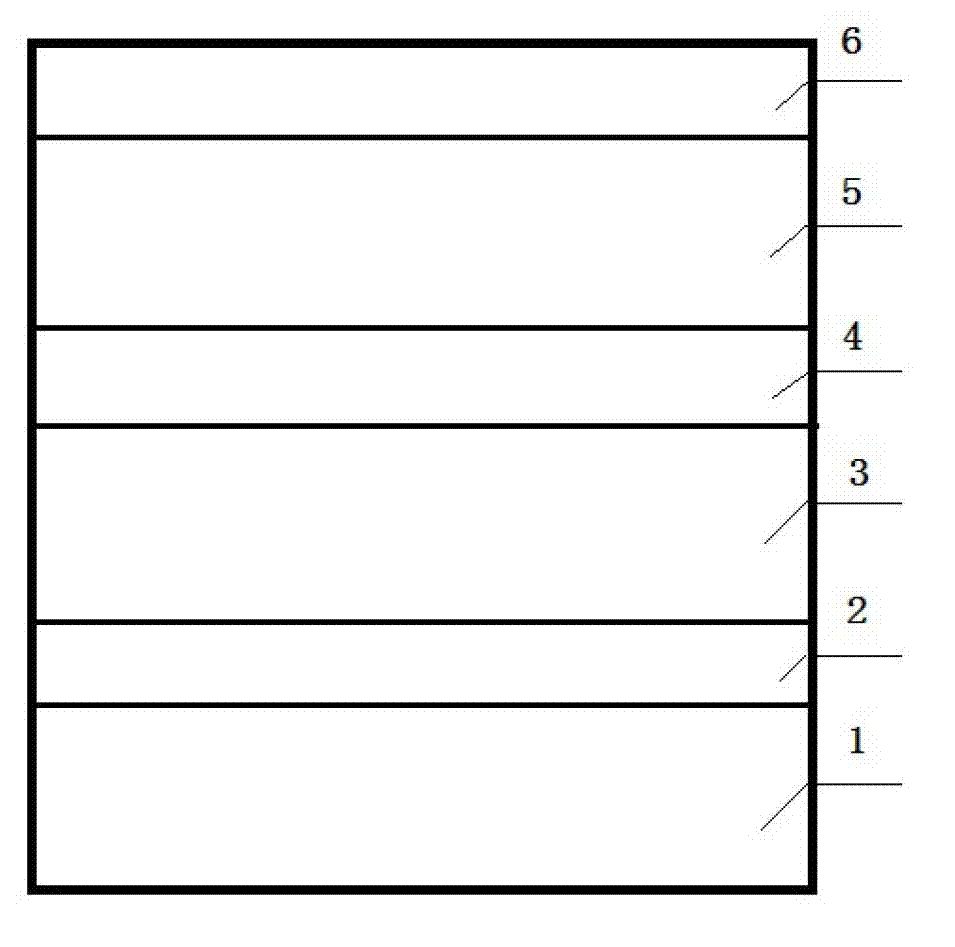

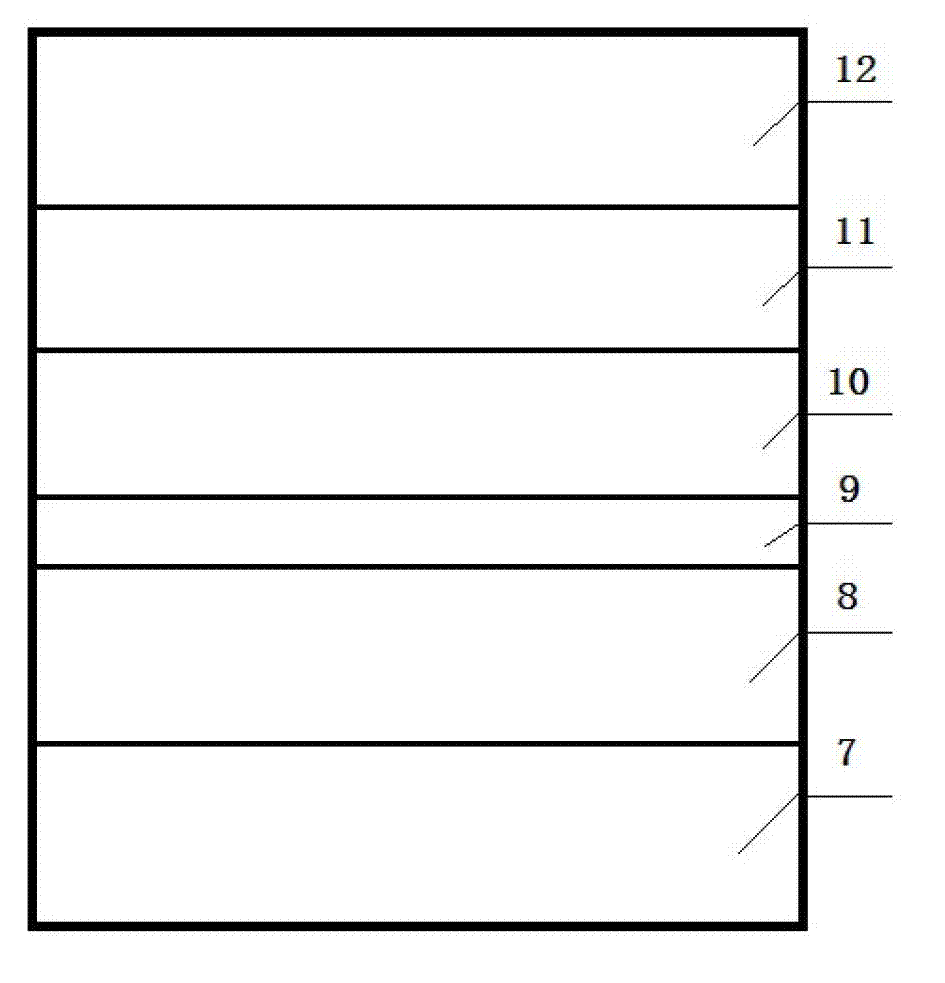

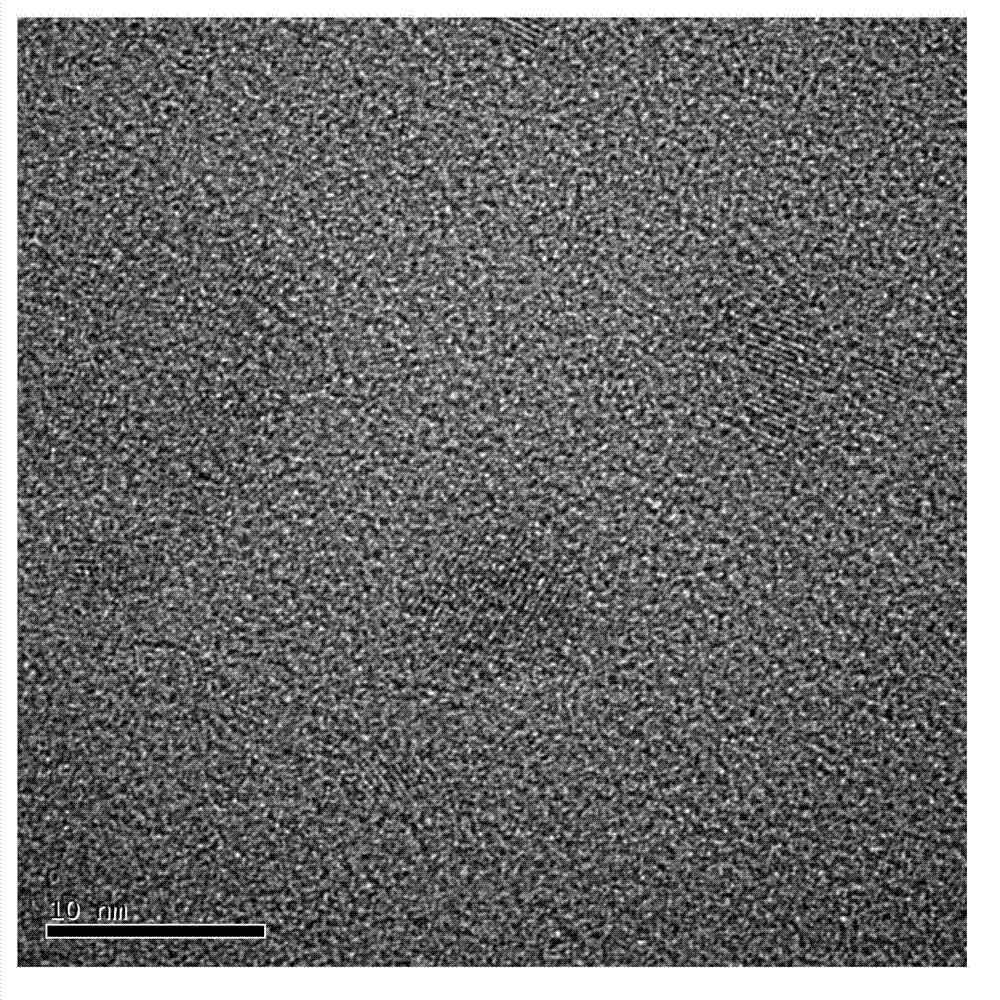

[0023] A p-type amorphous silicon carbon-nanoparticle silicon multiple quantum well window layer material, such as figure 1 As shown, it is a multi-layer material prepared by the layer-by-layer deposition method, which is alternately grown by wide-bandgap amorphous silicon-carbon films and narrow-bandgap p-type nanoparticle silicon films. Amorphous silicon-carbon films 1, 3, and 5 are plasma-enhanced The chemical vapor deposition technology is prepared under the condition that the substrate temperature is 150°C. The reaction gas is a mixed gas of silane, methane and hydrogen, and the volume flow percentage is: silane accounts for 0.5%, methane accounts for 4.5%, hydrogen is the balance, and amorphous silicon The thickness of the carbon film is 5nm, and the carbon content in the film is 70%. The p-type nanoparticle silicon films 2, 4, and 6 are prepared by plasma-enhanced chemical vapor deposition at a substrate temperature of 75°C, and the glow power density is 0.75W / cm 2 , t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com