Solar thin-film cell and manufacture method thereof

A solar thin film and thin film battery technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low output power, low voltage and current of solar cells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to further understand the present invention, several preferred embodiments of the present invention are listed below, together with the accompanying drawings, the composition and beneficial effects of the present invention are described in detail.

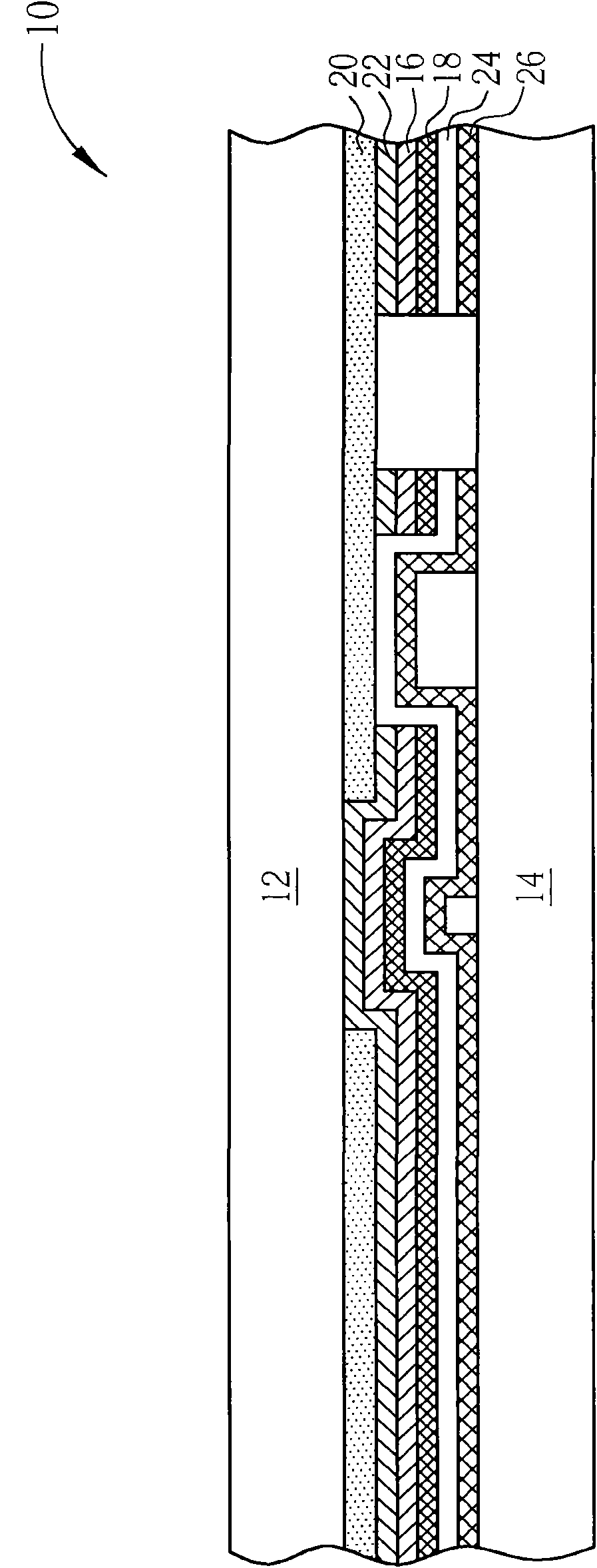

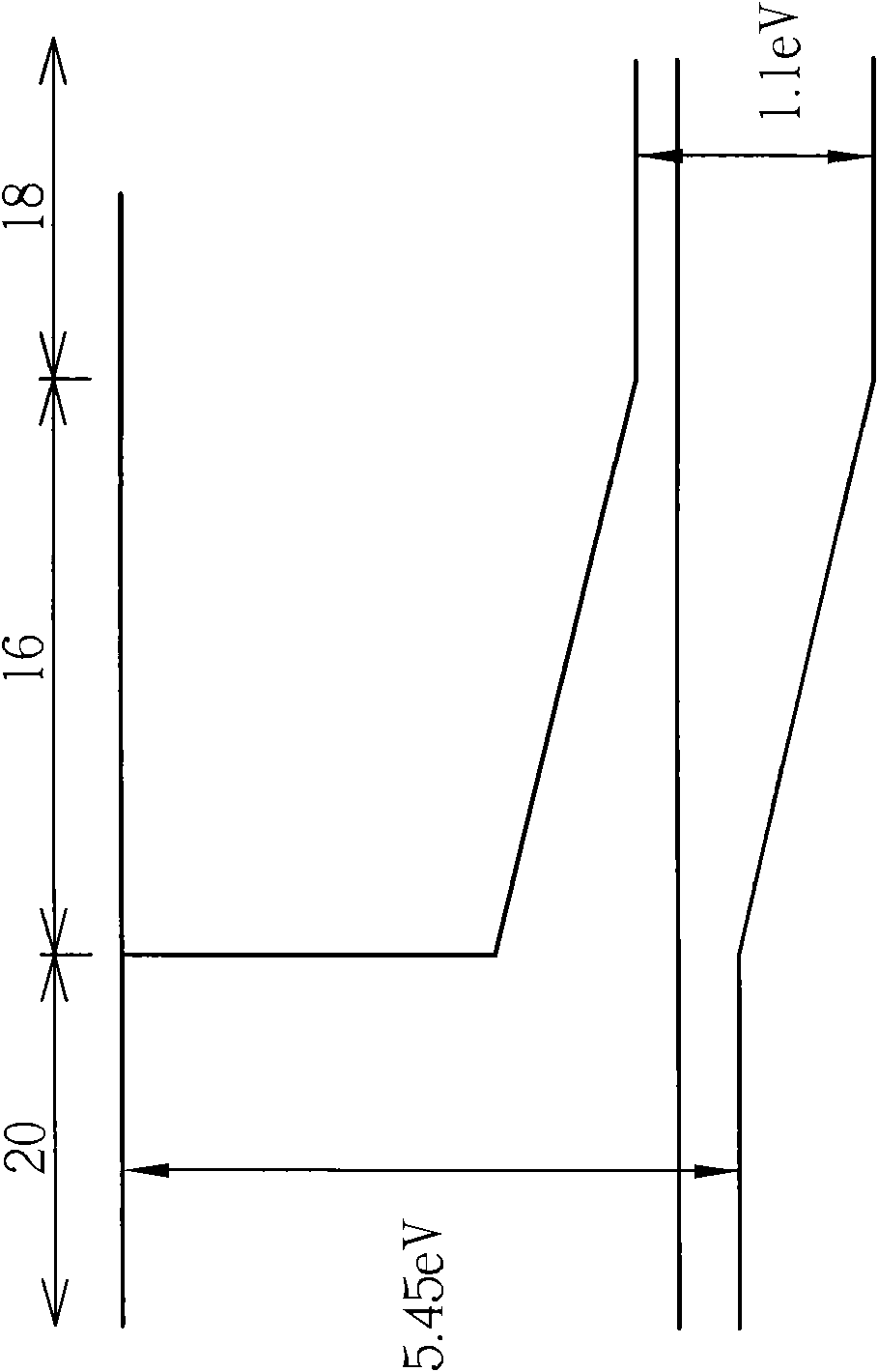

[0036] Please refer to figure 1 . figure 1 It is a schematic diagram of the solar thin film battery according to the first preferred embodiment of the present invention. Such as figure 1 As shown, the solar thin film battery 10 of the present embodiment includes a first substrate 12, a second substrate 14, an intrinsic (intrinsic) semiconductor layer 16, an N-type doped semiconductor layer 18, a P-type doped polycrystalline A diamond (P doped poly crystalline diamond) layer 20 , a P-type doped semiconductor layer 22 , a first transparent conductive layer 24 and a reflective electrode 26 . In this embodiment, the first substrate 12 and the second substrate 14 are substantially pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com