Heterojunction solar cell and manufacturing method thereof

A technology of solar cells and heterojunctions, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced production costs, expensive equipment, and high cost of ion implantation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

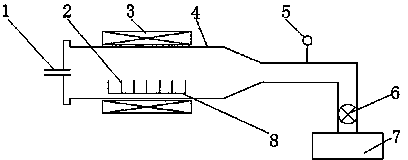

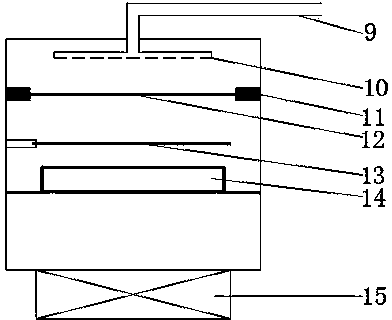

Image

Examples

Embodiment 1

[0035] Embodiment one: A heterojunction solar cell prepared by porous silicon layer transfer technology and a preparation method thereof, comprising the following steps:

[0036] (1) Carry out anodic oxidation treatment on the cleaned p-type single crystal silicon wafer, the specific process is as follows: first pass a small current of 3mA for 30s to form a small hole layer on the surface of the silicon wafer; then pass a large current of 100mA for 50s, A macroporous layer is formed under the small pore layer. The solution used for anodic oxidation is 40% hydrofluoric acid and 99.9% absolute ethanol, and the volume ratio is 1:1.

[0037] (2) Anneal the silicon wafer after the above treatment in a hydrogen atmosphere to close the small pore layer and restore the single crystal structure. At the same time, the pore size of the large pore layer will increase to facilitate the layer transfer process. The specific process is as follows: pressure controlled at 3×10 3 Pa, the ...

Embodiment 2

[0051] Embodiment two: Put the remaining silicon wafer after stripping in Example 1 into a container containing 25% sodium hydroxide solution, heat the entire container to 80°C for 10 minutes, and then transfer the silicon wafer to 1% hydrofluoric acid Rinse in medium for 60s, and finally rinse with deionized water and blow dry with nitrogen. Then repeat the process of embodiment one.

[0052] Implementation results: tested at AM1.5, temperature 25°C, its Voc is 531mV, Jsc is 32.65mA / cm 2 , FF is 0.6755, η=11.7%.

Embodiment 3

[0053] Embodiment three: Put the remaining silicon wafer after stripping in Example 2 into a container with 25% sodium hydroxide solution, heat the entire container to 80°C for 10 minutes, and then transfer the silicon wafer to 1% hydrofluoric acid Rinse in medium for 60s, and finally rinse with deionized water and blow dry with nitrogen. Then repeat the process of embodiment one.

[0054] Implementation results: Tested at AM1.5, temperature 25°C, its Voc is 533mV, Jsc is 32.30mA / cm 2 , FF is 0.6761, η=11.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com