Cathode interface modification layer material and perovskite solar cell

A solar cell and cathode interface technology, applied in the field of solar cells, achieves the effects of simple operation, process compatibility and roughness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

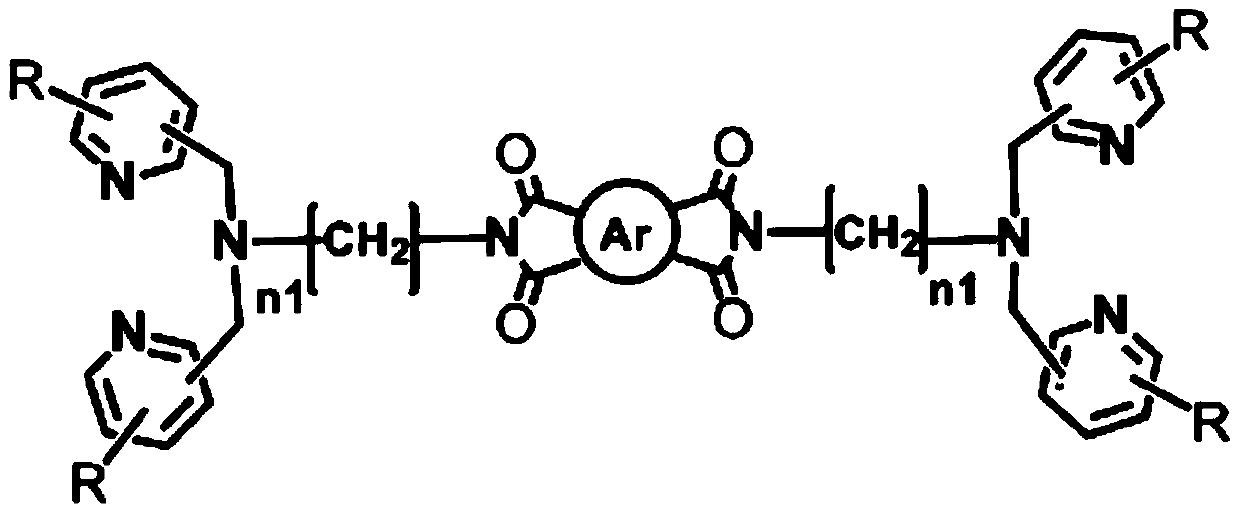

[0028] Ar is n1=2, R is a hydrogen atom (H); its molecular structural formula is:

[0029]

[0030] Its synthetic route is as follows:

[0031]

[0032] In a 100ml single-necked bottle, dissolve ethylenediamine (11.4mmol) in 50mL chloroform solution, slowly add di-tert-butyl dicarbonate (0.5g, 2.29mmol) dissolved in 10mL chloroform solution, stir at room temperature for 12 hours, spin dry The solvent was packed into a column, and compound 1 was obtained by separation with methanol, chloroform and a small amount of triethylamine as eluents. Compound 1 (0.8g, 5.0mmol), 2-chloromethylpyridine hydrochloride (1.8g, 10.9mmol) and sodium carbonate (2.4g, 22.6mmol) were dissolved in 15mL of dry ethanol solution, under nitrogen atmosphere Stir for 12 hours, spin to dry the solvent, add 50 mL of sodium hydroxide aqueous solution, and then extract with dichloromethane three times, dry with anhydrous potassium carbonate, pack into a column, and separate with ethyl acetate as the ...

Embodiment 2

[0034] Ar is n=1, R is a hydrogen atom (H); its molecular structural formula is:

[0035]

[0036] Its preparation method is as follows:

[0037]

[0038] In a 250ml single-necked bottle, 2g (10mmol) of compound 1 and 1.38g (10mmol) of potassium carbonate were dissolved in 120ml of acetonitrile, and the acetonitrile solution of 1.98g (10mmol) of compound 2 was slowly added dropwise. Heat to reflux overnight, cool, pour the mixed solution into ice water, extract with DCM (dichloromethane), spin the organic phase to dryness and concentrate, pack into a column, use DCM: ACE (dichloromethane: acetone) = 1:1 as elution agent, separated to obtain 2.5 g of light yellow liquid, and the yield was 81%.

[0039] 1 H NMR (CDCl 3 , 300MHz), (ppm): 2.68(t, 2H), 3.88(t, 2H), 4.06(s, 4H), 7.25~7.31(m, 4H), 7.78(m, 2H), 8.49(d, 2H ).

[0040]

[0041]In a 100ml pressure bottle, 0.54g (2mmol) of compound 4 and 0.818g (6mmol) of potassium carbonate were added to 50ml of DMF solut...

Embodiment 3

[0044] Step 1. Device preparation

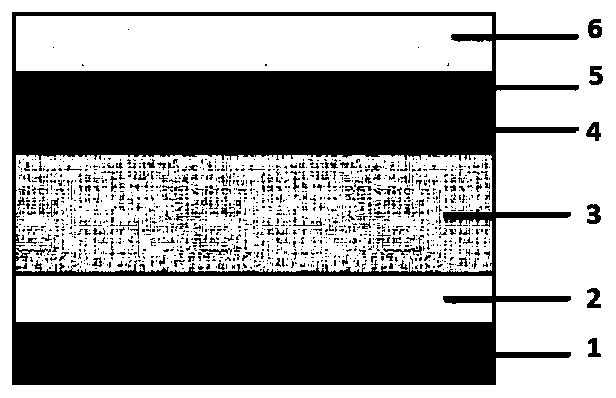

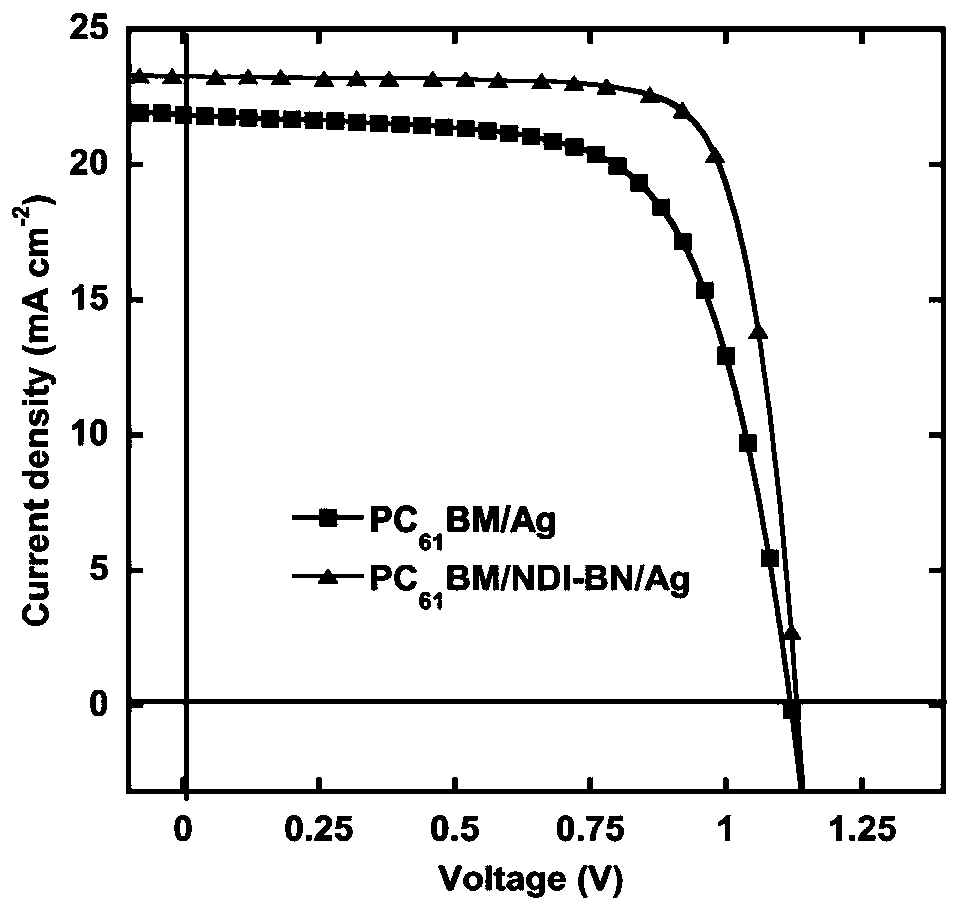

[0045] (1) if figure 1 The preparation of the inverted structure perovskite solar cell device ITO / PTAA / Perovskite Layer / PC61BM / NDI-BN / Ag with interface modification layer shown (PTAA represents poly[bis(4-phenyl)(2,4,6 -Trimethylphenyl)amine], Perovskite Layer represents the perovskite layer, PC61BM represents a fullerene derivative [6,6]-phenyl-C61-butyric acid methyl ester, Ag represents silver, and 1 in the figure is ITO, 2 is PTAA, 3 is Perovskite Layer, 4 is PC61BM, 5 is NDI-BN, 6 is Ag):

[0046] The patterned ITO glass substrates were washed sequentially with acetone, water and ethanol, and washed with N 2 Airflow drying followed by plasma treatment for 1 min. PTAA was dissolved in toluene at a concentration of 2 mg / ml, spin-coated onto a patterned ITO glass substrate (approximately 7 nm thick) at 3500 rpm for 15 seconds, and then annealed at 110 °C for 15 minutes. To enhance the wettability of PTAA to the perovskite solution, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com