Silicon carbon window layer film with refractive index gradient characteristics and application

A technology of gradient refractive index and window layer, which is applied in coating, final product manufacturing, metal material coating process, etc., and can solve problems affecting battery performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

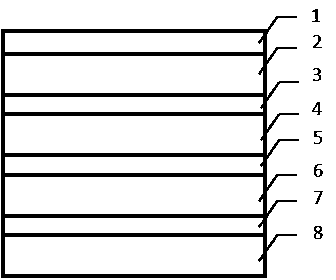

[0026] A method for preparing a silicon-carbon window layer thin film with a graded refractive index feature:

[0027] Put the sample to be processed into a high-vacuum plasma-enhanced chemical vapor phase RF-PECVD deposition equipment, the reaction temperature is 100 ° C, the reaction gas source is a mixed gas of silane, borane, hydrogen and methane, and the percentage of hydrogen in the gas volume flow rate is 98.55% %, the percentage of silane in gas volume flow is 0.75%, the percentage of borane in gas volume flow is 0.1%, the percentage of methane in gas volume flow is 0.6%, and the initial glow power density is 20 mW / cm 2 , as the thickness of the deposited film increases, the glow power density increases gradually to 50 mW / cm according to: P(t)=20+1.15t, where P(t) is the glow power density, and t is the deposition time 2 , the final glow deposition thickness is 30 nm, and the refractive index at the wavelength of 400 nm increases from 2.8 to 2.2 in the longitudinal gro...

Embodiment 2

[0033] A method for preparing a silicon-carbon window layer thin film with a graded refractive index feature:

[0034] Put the sample to be processed into a high-vacuum microwave plasma chemical vapor deposition system, the reaction temperature is 150°C, and the reaction gas source is a mixed gas of silane, borane, hydrogen and methane, of which hydrogen accounts for 98% of the gas volume flow rate, and silane accounts for The percentage of gas volume flow is 1%, the percentage of borane in gas volume flow is 0.2%, the percentage of methane in gas volume flow is 0.8%, and the glow power density is initially 10 mW / cm 2 , as the thickness of the deposited film increases, the glow power density increases gradually to 40 mW / cm according to: P(t)=10+1.5t, where P(t) is the glow power density, and t is the deposition time 2 , the final glow deposition thickness is 30 nm, and the refractive index at the wavelength of 400 nm increases from 2.8 to 2.2 in the longitudinal growth directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com