Nitrogen-doped carbon-inlaid non-noble metal catalyst and preparation method and application thereof

A non-precious metal and catalyst technology, applied in the field of nitrogen-doped carbon inlaid non-precious metal catalyst and its preparation, can solve the problems of precursor framework collapse, low specific surface area and pore volume, and complex crystals, and achieve the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 0.5g of cobalt phthalocyanine and 5.0g of commercial silica nanoparticles and add them to the ethanol-chloroform mixed solvent, stir and mix in a water bath, and then spin evaporate to remove the solvent. The obtained solid powder is placed in a high-temperature quartz boat, and then Put it into the middle area of the tube furnace, raise the temperature to 700°C at a rate of 3°C / min in an atmosphere with a nitrogen flow rate of 50 mL / min and keep it constant for 4 hours, then cool to room temperature and take it out. The obtained black powder was added into 1.0 mol / L sodium hydroxide solution, stirred at room temperature for 12 hours, filtered and washed with water and dried to obtain a nitrogen-doped carbon-embedded non-precious metal catalyst.

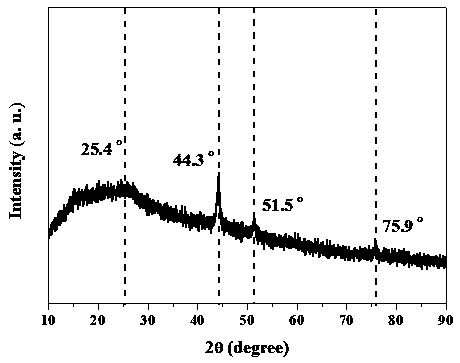

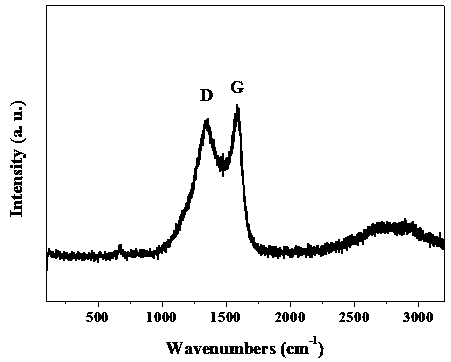

[0037] attached figure 1 The transmission electron microscope image shows that metal Co nanoparticles with a size of about 12-18nm are embedded in the porous nitrogen-doped carbon catalytic material structure, which is...

Embodiment 2

[0041] Weigh 1.0g of phenanthroline cobalt and 5.0g of commercial silica nanoparticles and add them to ethanol-chloroform mixed solvent, stir and mix in a water bath, and then spin evaporate to remove the solvent. The obtained solid powder is put into a high-temperature quartz boat, and then It was placed in the middle area of the tube furnace, raised to 800°C at a rate of 3°C / min in an atmosphere of nitrogen flow rate of 100mL / min and kept constant for 4 hours, then cooled to room temperature and taken out. The obtained black powder was added into 1.0 mol / L sodium hydroxide solution, stirred at room temperature for 12 hours, filtered and washed with water and dried to obtain a nitrogen-doped carbon-embedded non-precious metal catalyst.

Embodiment 3

[0043] Weigh 1.0g of cobalt phthalocyanine and 2.5g of commercial silica nanoparticles and add them to the ethanol-chloroform mixed solvent, stir and mix in a water bath, and then spin evaporate to remove the solvent. The obtained solid powder is placed in a high-temperature quartz boat, and then Put it into the middle area of the tube furnace, raise the temperature to 900°C at a rate of 5°C / min in an atmosphere of nitrogen flow rate of 100 mL / min, keep it constant for 4 hours, cool to room temperature and take it out. The obtained black powder was added into 0.5 mol / L sodium hydroxide solution, stirred at room temperature for 12 hours, filtered, washed and dried, and a nitrogen-doped carbon embedded non-precious metal catalyst was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com