Alnico-based magnetic particles for security ink

A technology of magnetic particles and particles, applied in the directions of inks, magnetic objects, magnetic materials, etc., can solve the problems of reduced anti-counterfeiting, difficult reflection of sunlight by magnetic particles, large powder oxidation problems, etc., achieving small composition deviation and improving infrared reflection ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

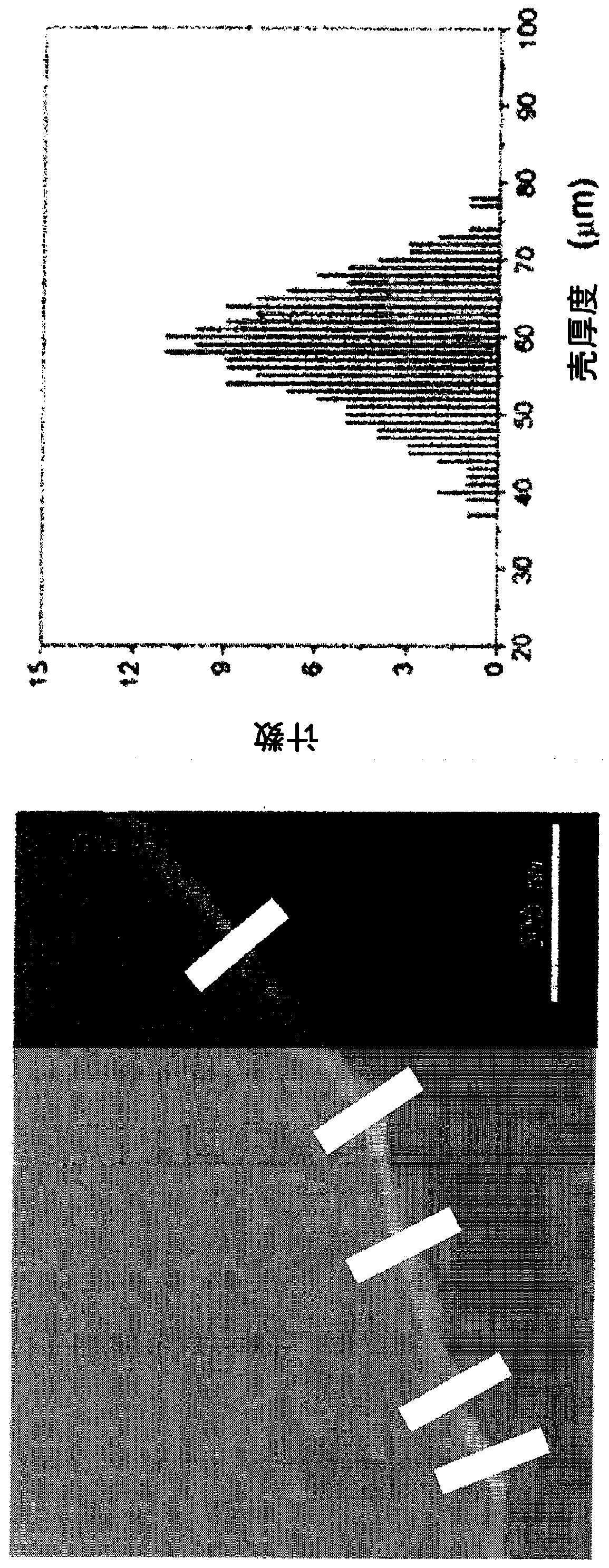

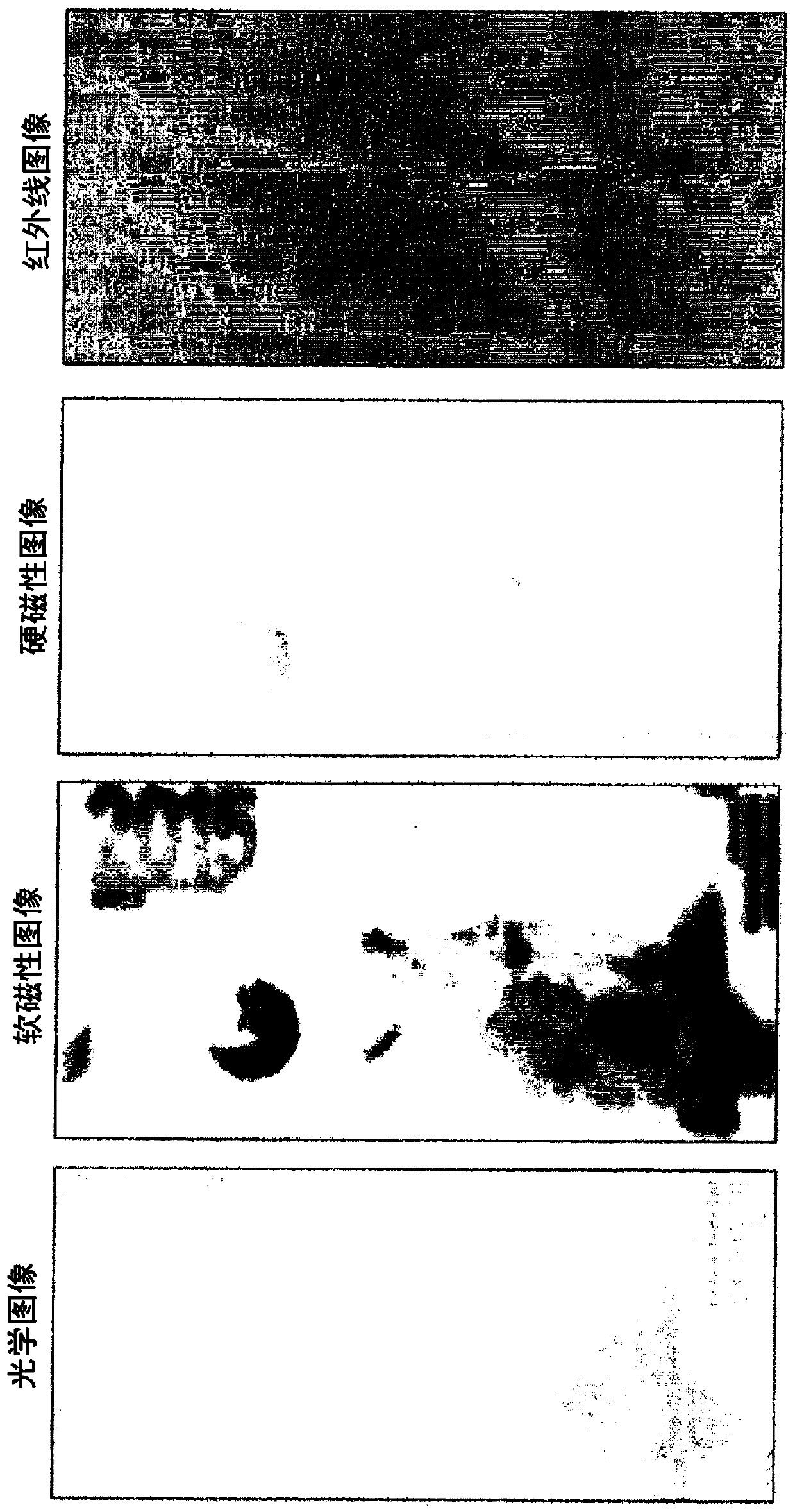

[0172] Using the AlNiCo-based magnetic particles produced in Example 1, an anti-counterfeit ink for a valuable document (hereinafter referred to as hard magnetic ink) was produced. Specifically, 18% by weight of the first varnish (Construction Chemical, KR-KU), 14% by weight of the second varnish (Construction Chemical, KR-KA), 10% by weight of the produced AlNiCo-based magnetic particles, and an extender (DongHo Calcium , TL-2000) 41% by weight, mixed wax (Micro Powders, Polyfluo 540XF) 6% by weight, aliphatic hydrocarbon (SKchemicals, YK-D130) 2% by weight, solvent (diethylene glycol monobutyl ether) 2% by weight, After mixing 5% by weight of surfactant (HANNONGCHEMICALS, Koremul-263Na) and 2% by weight of desiccant, they were put into a grinder and ground 4 to 5 times in the grinder to manufacture anti-counterfeiting ink.

[0173] Regarding the paramagnetic ink, an ink was produced using the same substance and composition as the above-mentioned hard magnetic ink, and 10% by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com