Evaporative cooling device

An evaporative cooling, plate technology, applied in natural cooling systems, energy-saving heating/cooling, heating methods, etc., can solve problems such as affecting temperature differences and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

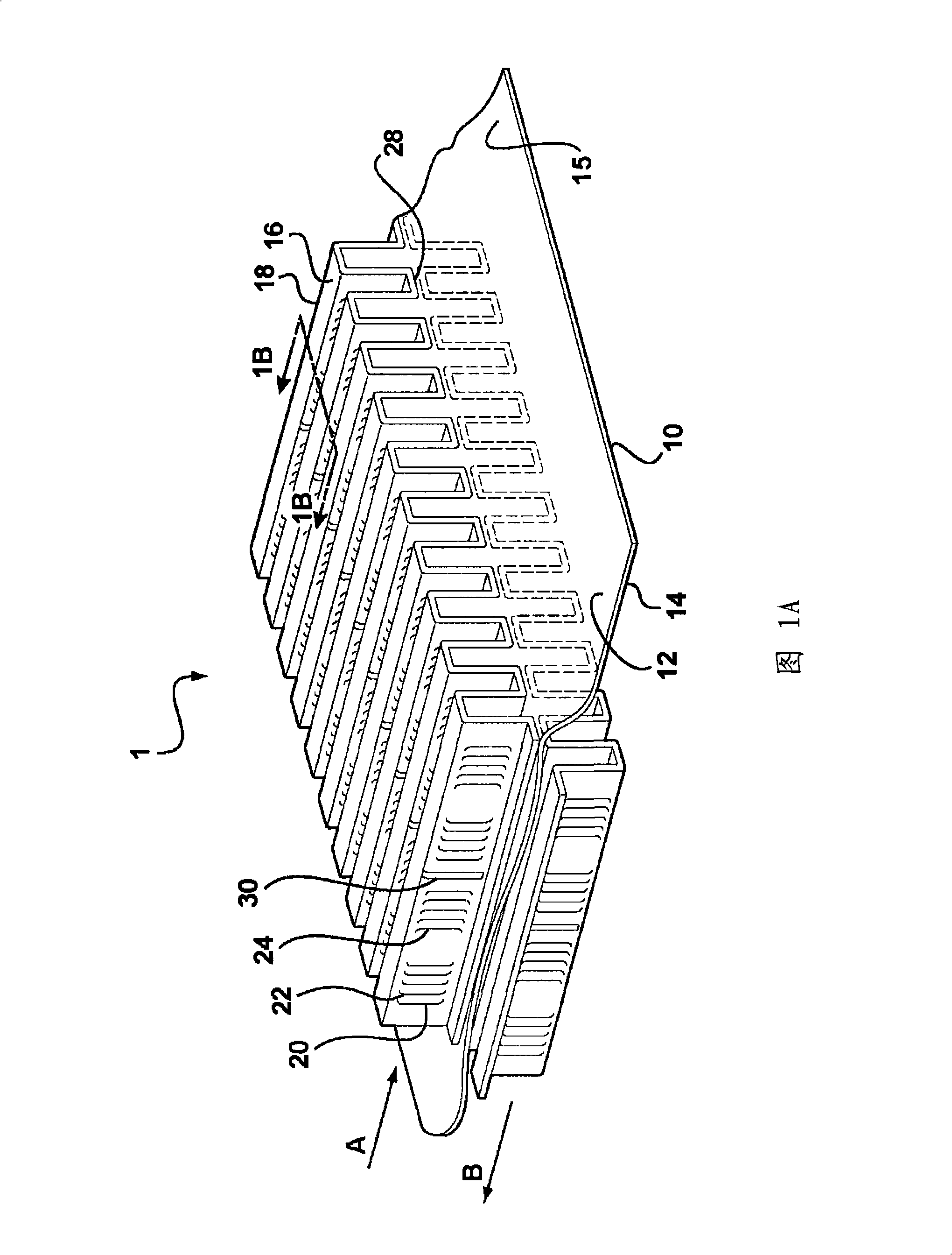

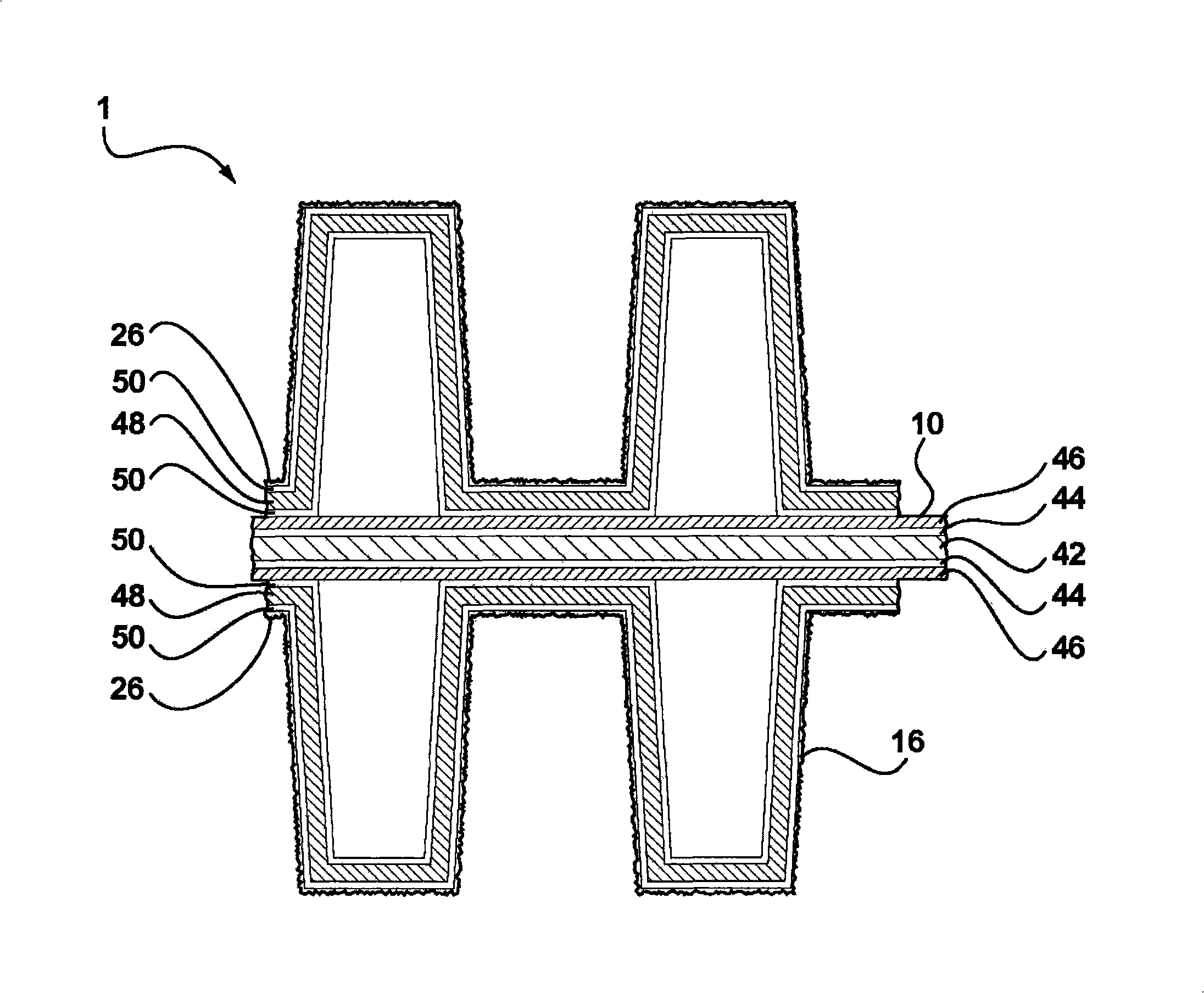

[0032] Figure 1A shows a part of a heat exchange element 1 of the type currently used in the prior art heat exchanger described in PCT Publication WO04 / 040219, the content of which is hereby incorporated by reference. The heat exchange element 1 comprises a membrane 10 having a first surface 12 and a second surface 14 . Arrows A and B indicate the flow direction of air for use as a dew point cooler. Arrow A represents the main air flow over the first surface 12 . Arrow B represents the secondary air flow over the second surface 14 . The membrane 10 is formed from a thin aluminum plate. Both sides of the membrane 10 are provided with flaps 16 arranged in strips 18 . The flaps 16 are attached to the film 10 at their bases 28 by heat seal adhesive. For this purpose, the tab 16 is also formed from aluminum laminated with a heat seal adhesive. In this type of evaporative cooling device, the heat exchange mainly takes place on the surface of the fins 16 on the second surface 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com