High temperature and high voltage experimental device for heating gasket

An experimental device, high temperature and high pressure technology, applied in the direction of applying stable tension/pressure to test material strength, material excitation analysis, Raman scattering, etc., can solve the problems of only reaching 450°C, oxidation damage of diamond anvil, etc., to achieve The effect of simple use, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

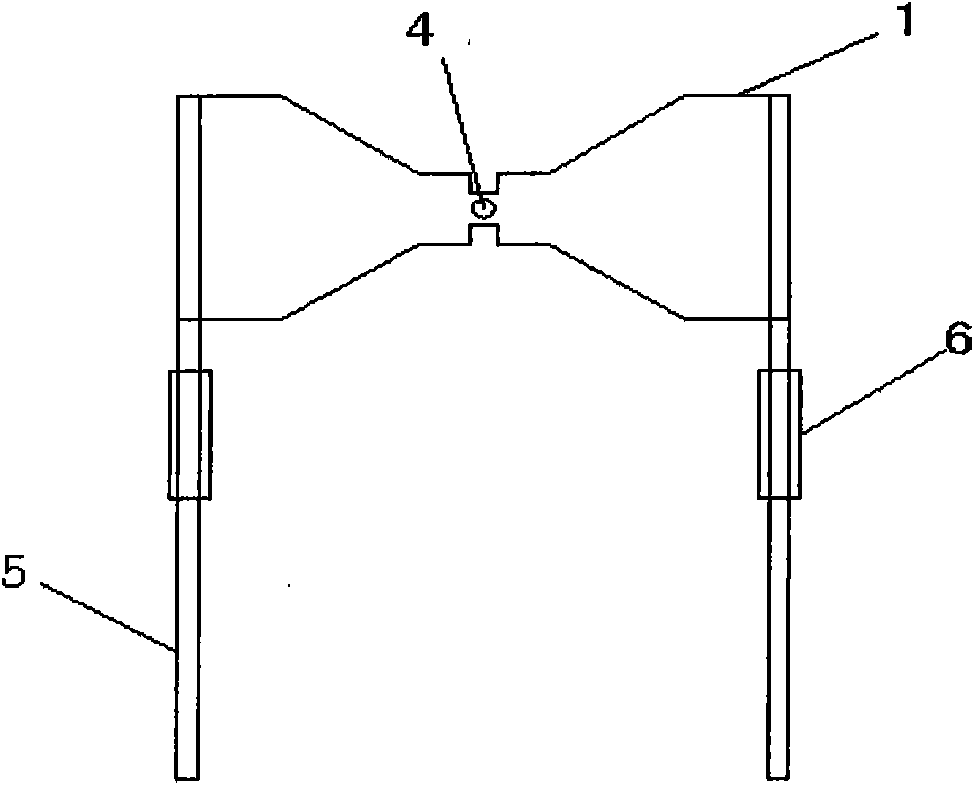

[0022] Embodiment 1 The shape and manufacture of the gasket 1, and the material of the insulating layer 2

[0023] to combine figure 1 The structure of the warming core pad of the present invention will be described. figure 1 Among them, gasket 1 is a T301 stainless steel sheet, which is made by laser cutting technology and fine grinding; the pressure groove in the middle of gasket 1 is pre-pressed by anvil 8 of diamond or white gem; the hole in the center of gasket 1 is used as a sample The heating cavity 4 can be made by artificial drilling. A solid copper wire can be used as the wire 5, and welded to both ends of the pad 1 by acetylene-oxygen electric welding. Lead 5 is put on porcelain tube 6, is to avoid press 7 and lead 5 Unicom, also plays fixing role.

[0024] Utilize mica sheet and magnesia or sodium chloride to fill in the pressure groove in the middle of gasket 1, cut off the direct contact between anvil 8 and heating source-gasket 1, use magnesia layer or sodium...

Embodiment 2

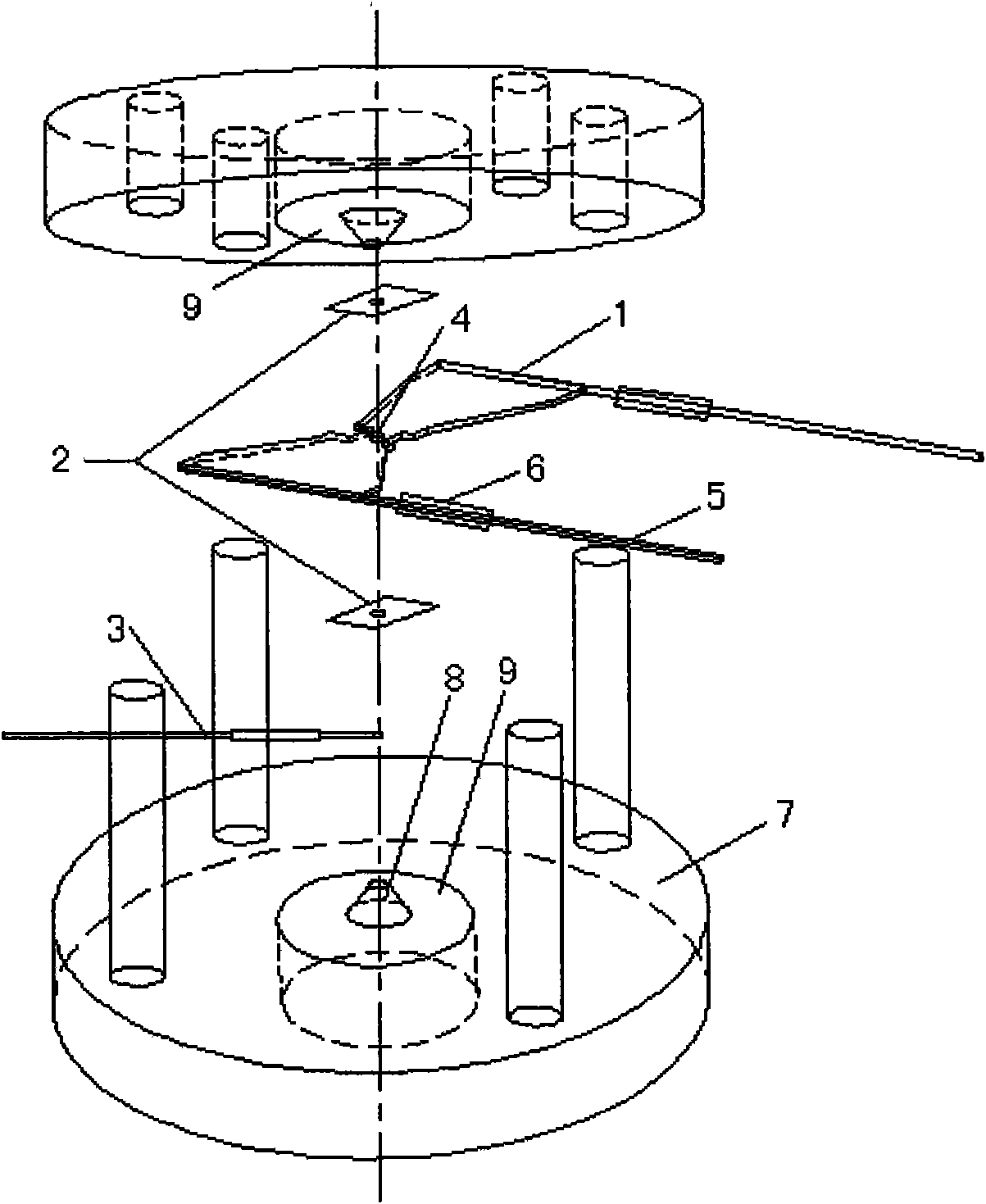

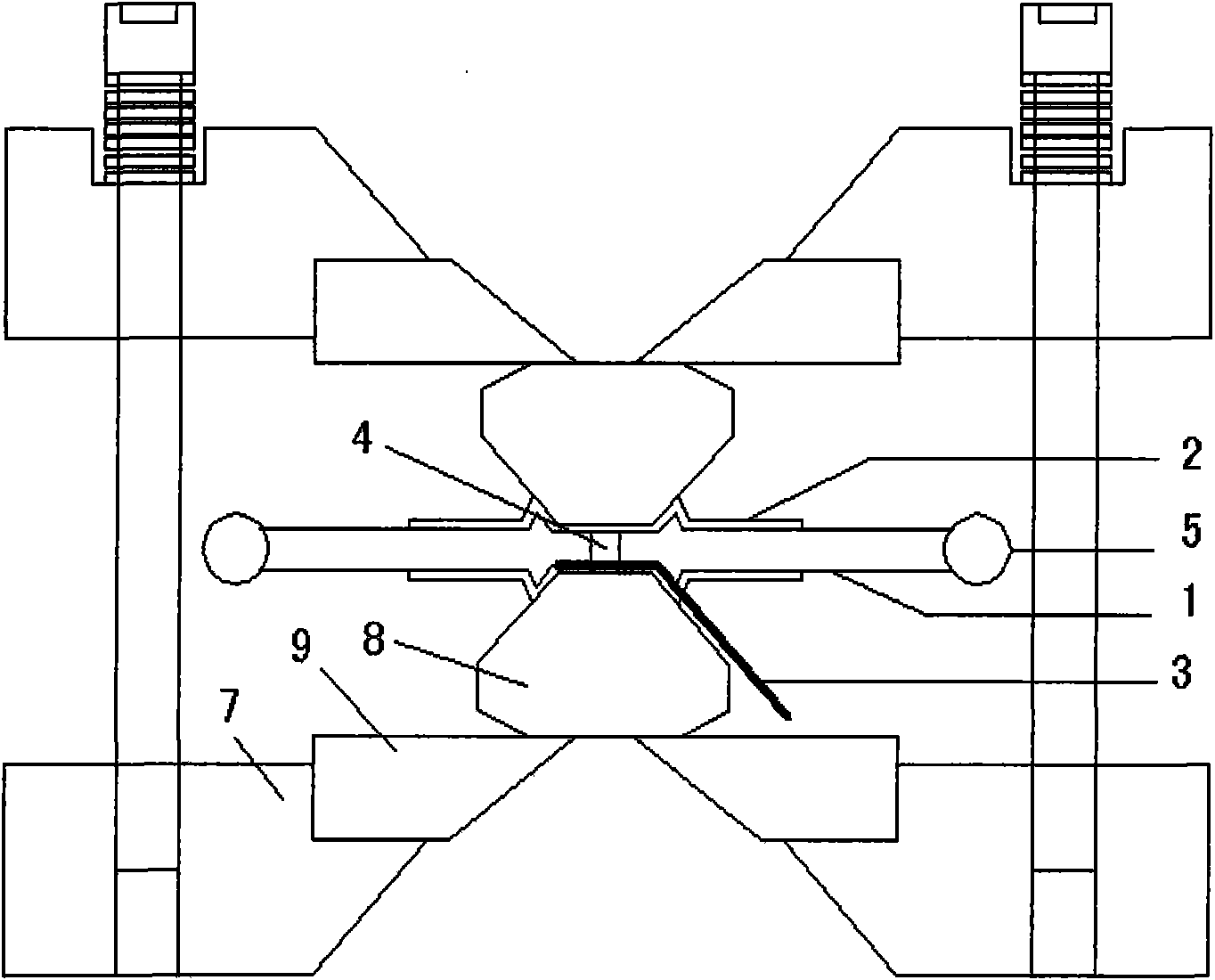

[0025] Embodiment 2 The structure of the device of the present invention, assembly

[0026] (1) see image 3 , the structure of the device of the present invention has: upper and lower anvils 8 form a pair of anvils, a gasket 1 is placed in the middle of the upper and lower anvils 8 for sealing pressure, and the upper and lower supporting blocks 9 are used as bases for the anvils. 9 and the anvil are placed in the cavity of the press 7 to implement high pressure on the sample between the anvil surfaces of the two anvils 8 . Such as figure 1 The gasket 1 is connected with direct current as the heating source, and the upper and lower sides of the gasket 1 are padded with mica sheets as the insulating layer 2 for pre-compression, and a layer of magnesium oxide or chlorine is laid in the pressure groove formed by the pre-pressing of the gasket 1 and the mica sheet. Sodium chloride layer; the thermocouple 3 for detecting temperature is placed under the lower insulation layer 2. ...

Embodiment 3

[0033] Embodiment 3 is to the measurement of sample

[0034]Using the device of the present invention to perform high-temperature and high-pressure in-situ Raman measurement on magnesium silicate shows that the device of the present invention can be fully used in the actual high-temperature and high-pressure spectrum measurement. Figure 4 It is the data map of the high temperature and high pressure in situ Raman experiment completed under the condition of 5GPa using a diamond anvil. Figure 5 It is the data map of the high temperature and high pressure in situ Raman experiment completed under the condition of 0.3GP using the white gemstone anvil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com