Ultrathin steel structure waterproof coating and preparation method thereof

A technology for fire retardant coatings and steel structures, applied in the direction of fire retardant coatings, coatings, etc., can solve the problems that the fire resistance effect is not as good as that of non-intumescent fire retardant coatings, the load of steel structure increases greatly, the application effect is not ideal, etc. The effect of aging, improving thermal insulation ability, and high expansion ratio of coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

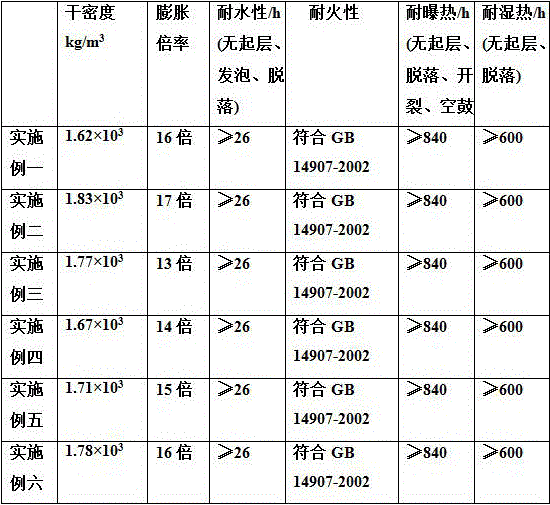

Examples

Embodiment 1

[0050] S0: Spherical nano-silica airgel particles with a diameter of 50nm were selected, and the surface was firstly modified by grafting hydrophobic groups, specifically using trimethylchlorosilane grafting to replace hydroxyl groups;

[0051] S1: Prepare materials according to the following component ratios: 10 parts of modified nano-silica airgel, 20 parts of acrylic emulsion, 45 parts of melamine, 40 parts of pentaerythritol, 70 parts of ammonium polyphosphate with a polymerization degree of 600, 10 parts of titanium dioxide, 5 parts of sepiolite fiber, 10 parts of talc, 15 parts of expandable graphite, 0.5 part of water-based wetting and dispersing agent, 0.03 part of modified organic bentonite, 0.1 part of water-based leveling agent;

[0052] S2: Put the components obtained in S1 into the high-speed disperser in turn, disperse at a low speed of 800r / pm for 10min, and then disperse at a high speed of 4000r / pm for 25min;

[0053] S3: standing and aging for 10 hours;

[00...

Embodiment 2

[0056] S0: Select spherical nano-silica airgel particles with a diameter of 100nm, and firstly modify the surface by grafting hydrophobic groups, specifically using hexamethyldioxysilane grafting to replace hydroxyl groups;

[0057] S1: Prepare materials according to the following component ratios: 5 parts of modified nano-silica airgel, 45 parts of acrylic emulsion, 30 parts of melamine, 30 parts of pentaerythritol, 50 parts of ammonium polyphosphate with a degree of polymerization of 800, 15 parts of titanium dioxide, 15 parts of sepiolite fiber, 5 parts of talc, 5 parts of expandable graphite, 0.2 part of water-based wetting and dispersing agent, 0.02 part of modified organic bentonite, 0.2 part of water-based leveling agent;

[0058] S2: Put the components obtained in S1 into the high-speed disperser in turn, disperse at a low speed of 1000r / pm for 20min, and then disperse at a high speed of 3000r / pm for 25min;

[0059] S3: standing and aging for 12 hours;

[0060] S4: Me...

Embodiment 3

[0062] S0: Spherical nano-silica airgel particles with a diameter of 150nm are selected, and the surface is firstly modified by grafting hydrophobic groups, specifically using triethylchlorosilane grafting to replace hydroxyl groups;

[0063] S1: Prepare materials according to the following component ratios: 15 parts of modified nano-silica airgel, 15 parts of acrylic emulsion, 60 parts of melamine, 60 parts of pentaerythritol, 60 parts of ammonium polyphosphate with a polymerization degree of 1000, 12 parts of titanium dioxide, 10 parts of sepiolite fiber, 15 parts of talc, 10 parts of expandable graphite, 0.8 part of water-based wetting and dispersing agent, 0.08 part of modified organic bentonite, 0.2 part of water-based leveling agent;

[0064] S2: Put the components obtained in S1 into the high-speed disperser in turn, disperse at a low speed of 900r / pm for 15min, and then disperse at a high speed of 5000r / pm for 20min;

[0065] S3: standing and aging for 15 hours;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com