Electric machine

A rotor and fan technology, applied in the field of automotive fan units, can solve the problem that the positioning of air ducts and similar components cannot completely eliminate functional defects, and achieve the effects of avoiding motor failure, high service life, and small structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

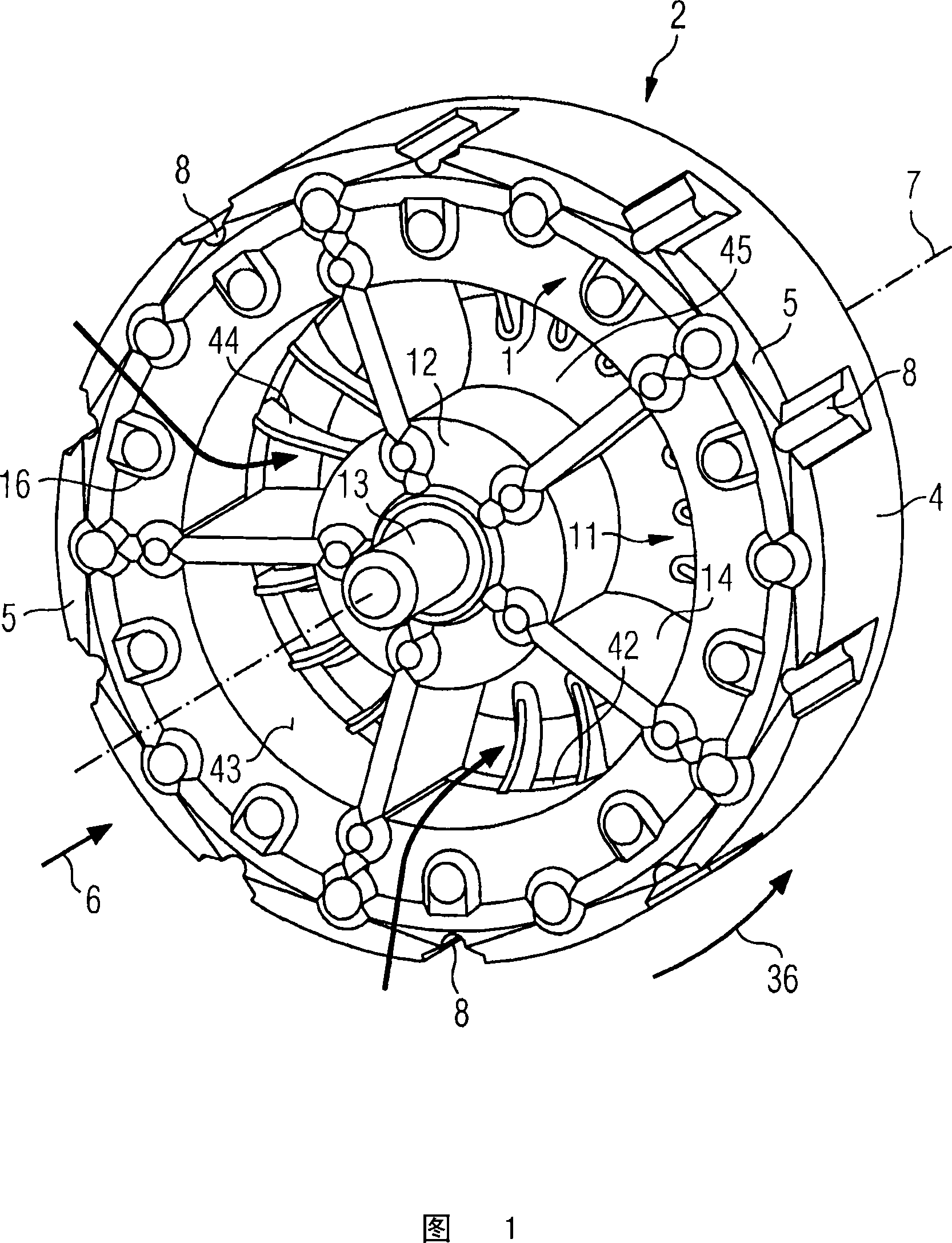

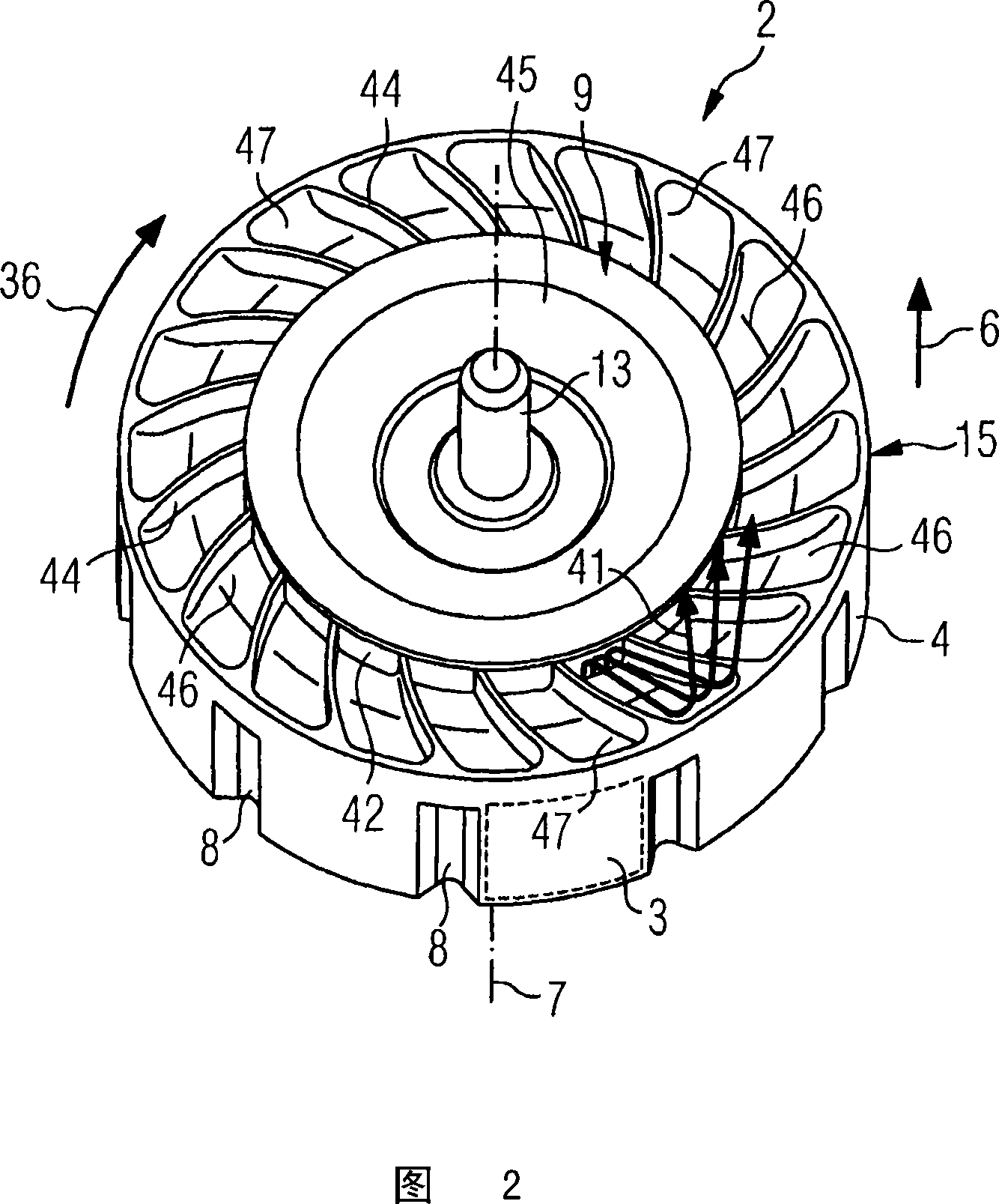

[0030] FIG. 1 shows a perspective view of the rear side 1 of a rotor 2 according to the invention. The rotor 2 is a permanently excited inner rotor of a brushless electromagnetic DC motor which is used in motor vehicles in particular as a radiator fan motor.

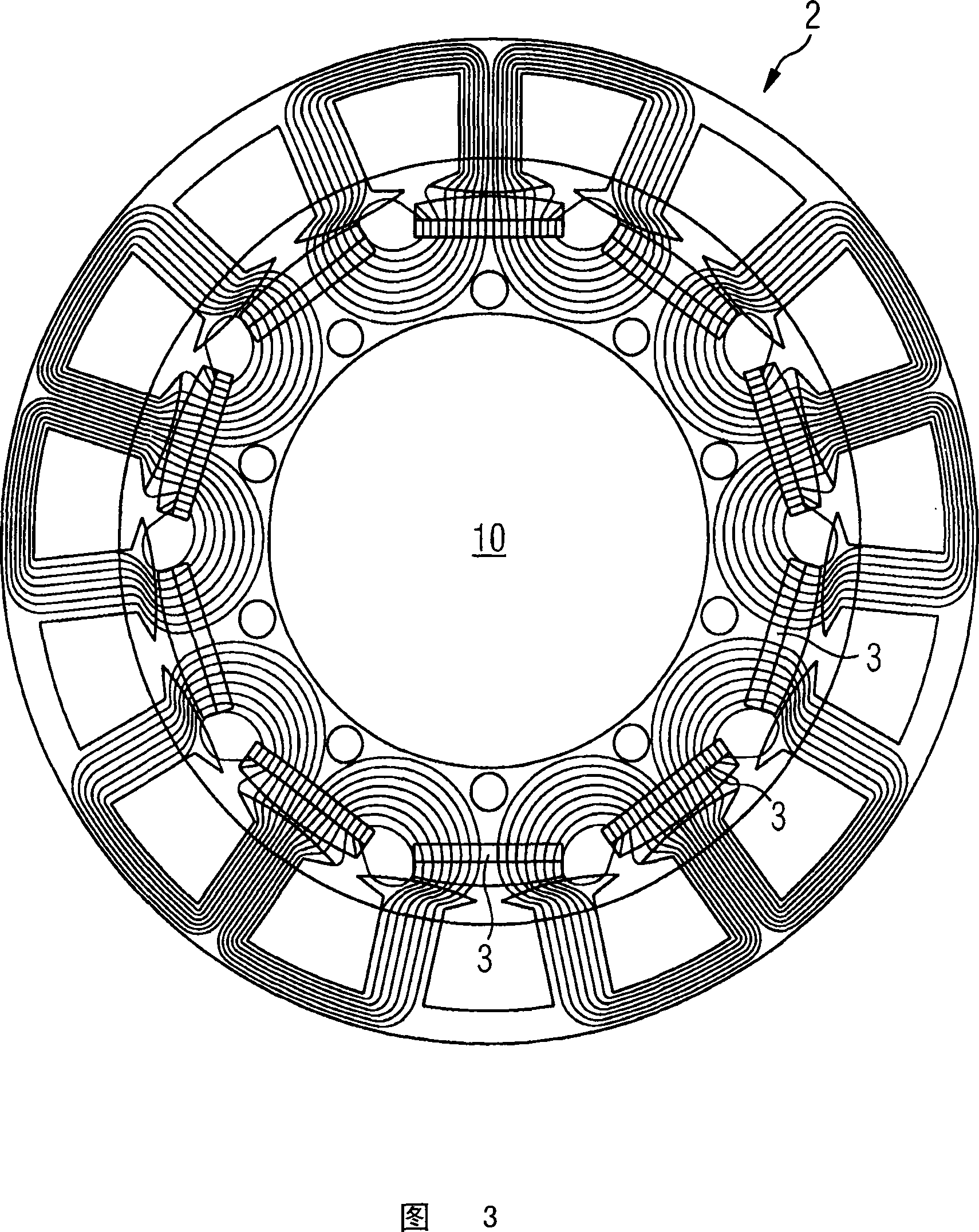

[0031] The rotor 2 has so-called pocket magnets 3 (indicated by dashed lines in FIG. 2 ). The magnets 3 are arranged at a distance from one another on the circumference 4 of the rotor 2 . The magnet 3 is for example a rare earth magnet based on NdFeB (Neodymium Iron Boron). Said magnets 3 are in pockets 5 molded in iron on the circumference 4 of the rotor. In order to prevent oxidation, the magnet 3 is extruded and encapsulated with plastic material. The advantage of such a magnet embedded in iron is that it is less prone to demagnetization even at high currents. Between the pockets 5 receiving the magnets 3 , on the circumference 4 of the rotor 2 , grooves 8 arranged in the axial direction 6 , ie parallel to the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com