Rotating electric machine integral with control device

A technology for controlling devices and rotating electrical machines, applied in electromechanical devices, cooling/ventilating devices, electrical components, etc., can solve the problems of overheating of components, high prices, and heating of the main body of the rotating motor of the front bracket, and achieves the purpose of suppressing heat conduction and effectively cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiment 1

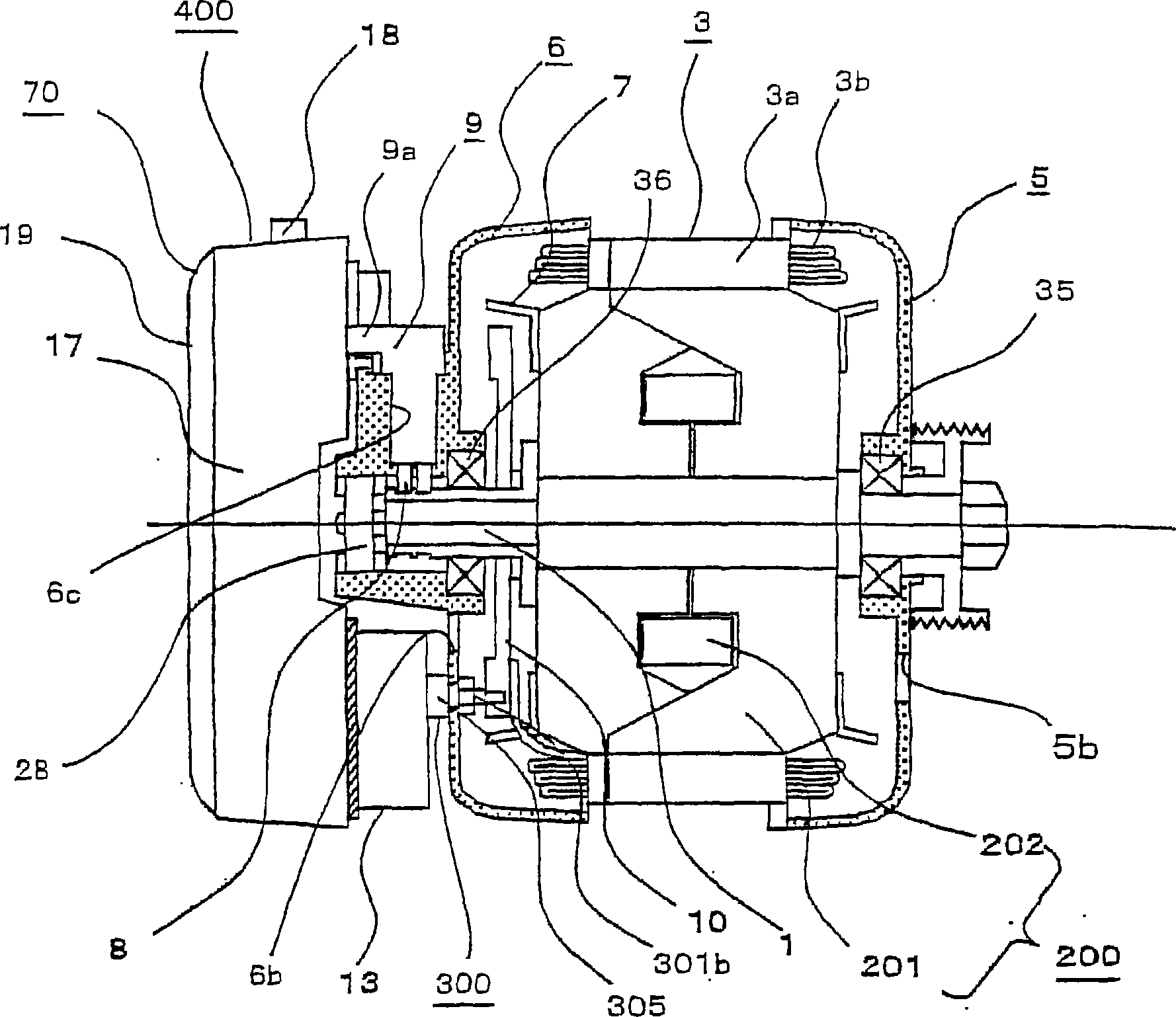

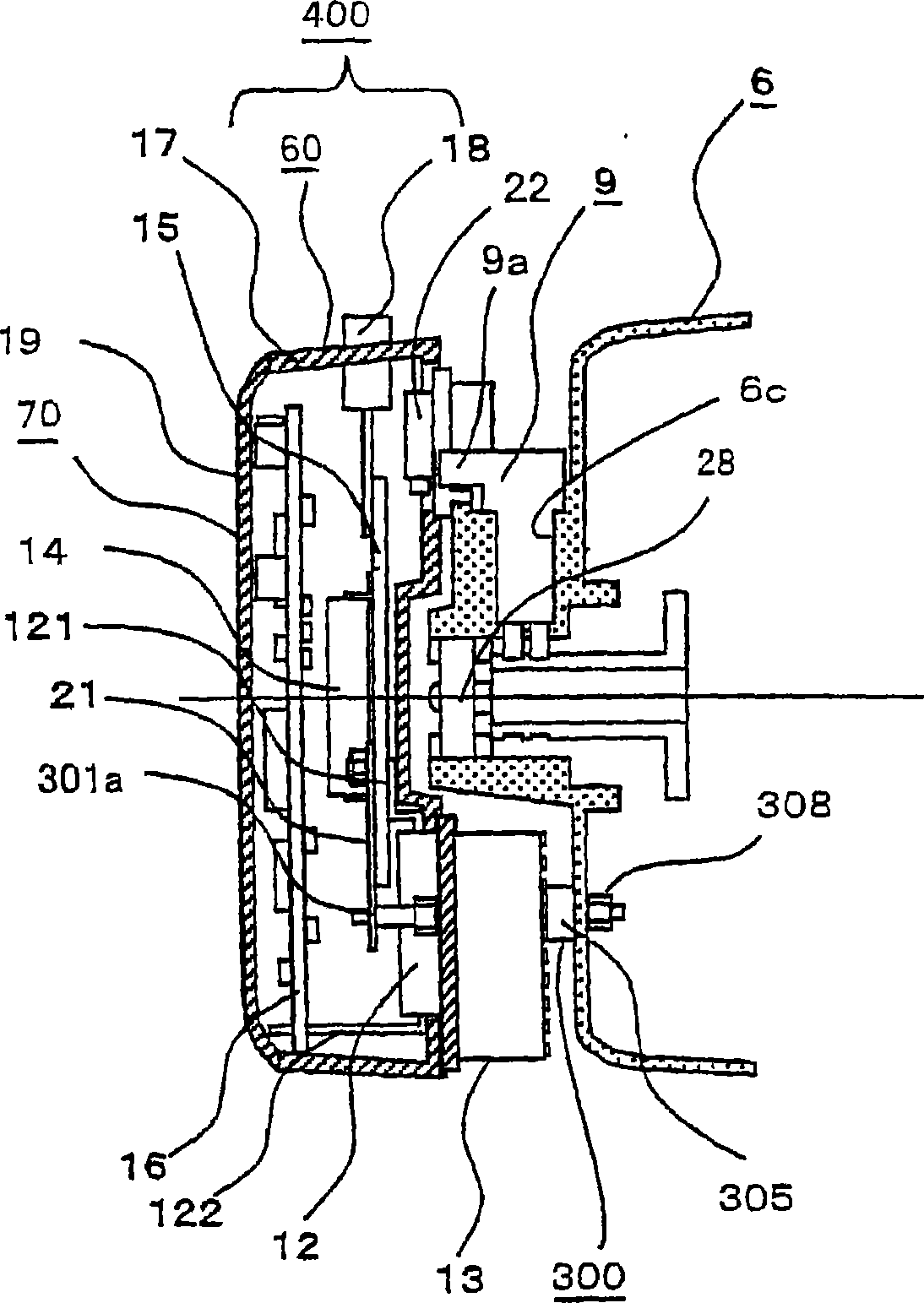

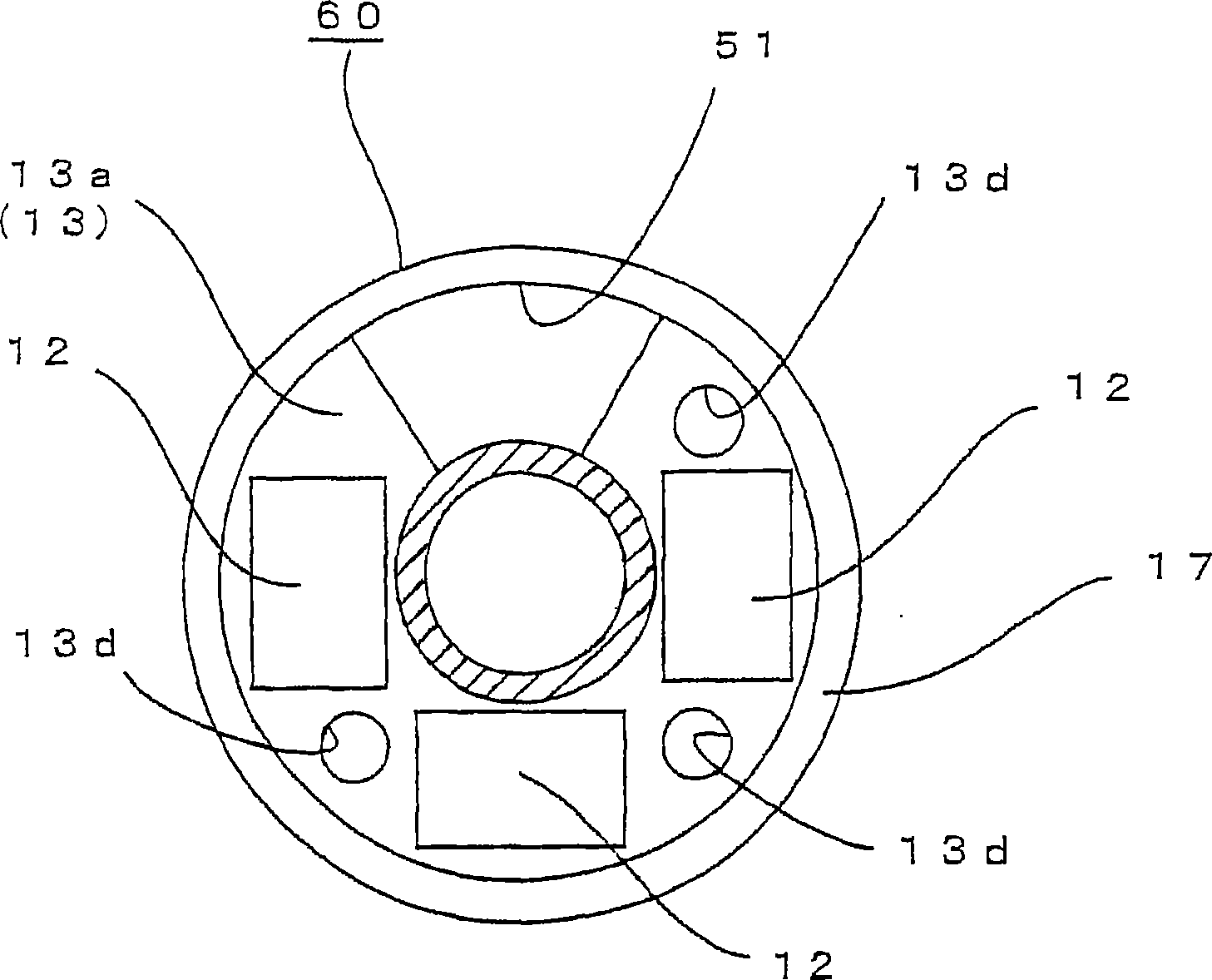

[0026] Figure 1 to Figure 10 Showing Embodiment 1 for carrying out the present invention, figure 1 is a partial cross-sectional view showing the configuration of a control-device-integrated rotating electrical machine, figure 2 is showing figure 1 A cross-sectional view of the detailed structure of the control device, image 3 It is a top view of the radiator periphery. Figure 4 is the top view of the radiator, Figure 5 It is a plan view showing the arrangement relationship between the switching element and the smoothing capacitor. Image 6 is the detailed structural diagram of the conductive stud bolt, Figure 7 It is an enlarged view of the mounting part where the radiator of the control unit is mounted on the rear bracket, Figure 8 It is an explanatory diagram for explaining the operation of fixing the conductive stud bolts to the heat sink. Figure 9 It is an explanatory diagram showing the flow of heat and cooling air of the rear bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com