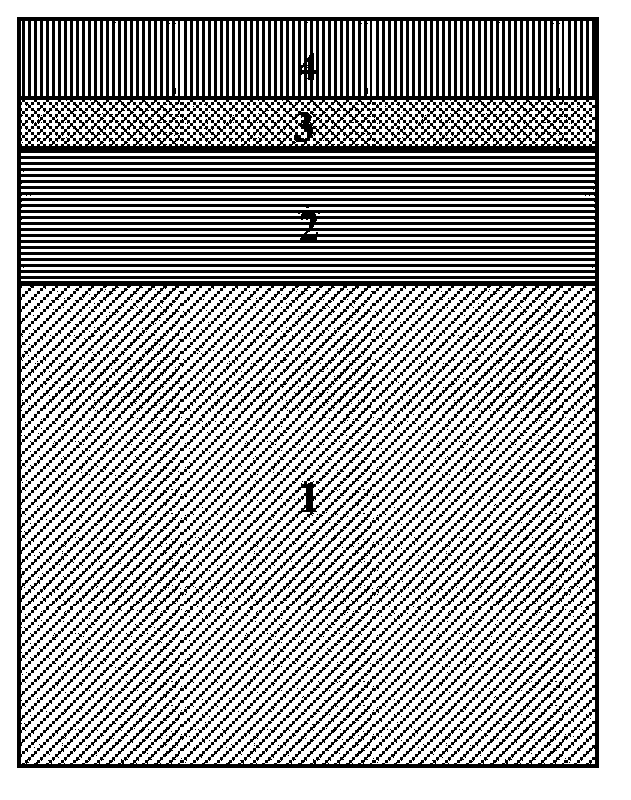

Composite gradient hydrogen-resistant coating for high-temperature evacuated collector tube and preparation method thereof

A vacuum heat collector tube and coating technology, applied in coating, chemical instruments and methods, metal material coating process, etc., can solve the problem of high requirements for coating preparation process and equipment, reduced hydrogen resistance effect of coating, and unfavorable large-scale production. Production and other problems, to achieve the effect of improving the ability of preventing hydrogen penetration and corrosion resistance, high density and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. The surface of the austenitic 316L stainless steel sample was polished with 300#, 600# and 1200# SiC water abrasive paper, sandblasted, put into acetone solution for ultrasonic cleaning for 15 minutes, and dried;

[0031] 2. Prepare Ni-Cr-Al intermediate transition coating (Cr content is 25wt%, Al content is 5wt%, and the rest is Ni) on the surface of stainless steel by low-pressure plasma spraying technology; the specific process parameters are: current 500A, voltage 65V, H 2 The flow rate is 10L / min, the Ar flow rate is 50L / min, the chamber pressure is 4000Pa, the spraying speed is 4mm / s, and the spraying distance is 100mm.

[0032] 3. Put the sample prepared by low-pressure plasma spraying into a vacuum furnace after ultrasonic cleaning, seal it, vacuumize it, the pressure is <10Pa, feed argon gas, the pressure is 100000Pa, then vacuumize, and cycle twice;

[0033] 4. Turn off the argon gas, pass the hydrogen gas, the pressure is 100000Pa, start heating, and set t...

Embodiment 2

[0038] 1. The surface of the austenitic 316L stainless steel sample was polished with 300#, 600# and 1200# SiC water abrasive paper, sandblasted, put into acetone solution for ultrasonic cleaning for 15 minutes, and dried;

[0039] 2. Prepare Ni-Cr-Al intermediate transition coating (Cr content is 25wt%, Al content is 5wt%, and the rest is Ni) on the surface of stainless steel by low-pressure plasma spraying technology; the specific process parameters are: current 550A, voltage 65V, H 2 The flow rate is 20L / min, the Ar flow rate is 60L / min, the chamber pressure is 4000Pa, the spraying speed is 4mm / s, and the spraying distance is 100mm.

[0040] 3. Put the sample prepared by low-pressure plasma spraying into a vacuum furnace after ultrasonic cleaning, seal it, vacuumize it, the pressure is <10Pa, feed argon gas, the pressure is 100000Pa, then vacuumize, and cycle twice;

[0041] 4. Turn off the argon gas, pass the hydrogen gas, the pressure is 100000Pa, start heating, and set t...

Embodiment 3

[0046] 1. The surface of the austenitic 316L stainless steel sample was polished with 300#, 600# and 1200# SiC water abrasive paper, sandblasted, put into acetone solution for ultrasonic cleaning for 15 minutes, and dried;

[0047] 2. Prepare Ni-Cr-Al intermediate transition coating (Cr content is 25wt%, Al content is 5wt%, and the rest is Ni) on the surface of stainless steel by low-pressure plasma spraying technology; the specific process parameters are: current 700A, voltage 60V, H 2 The flow rate is 15L / min, the Ar flow rate is 80L / min, the chamber pressure is 4000Pa, the spraying speed is 4mm / s, and the spraying distance is 100mm.

[0048] 3. Put the sample prepared by low-pressure plasma spraying technology into a vacuum furnace after ultrasonic cleaning, seal it, vacuumize it, the pressure is <10Pa, feed argon gas, the pressure is 100000Pa, then vacuumize, and cycle twice;

[0049] 4. Turn off the argon gas, pass the hydrogen gas, the pressure is 100000Pa, start heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com