Method for HVOF or LPPS restoration coating repair of a nickel-base superalloy article

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

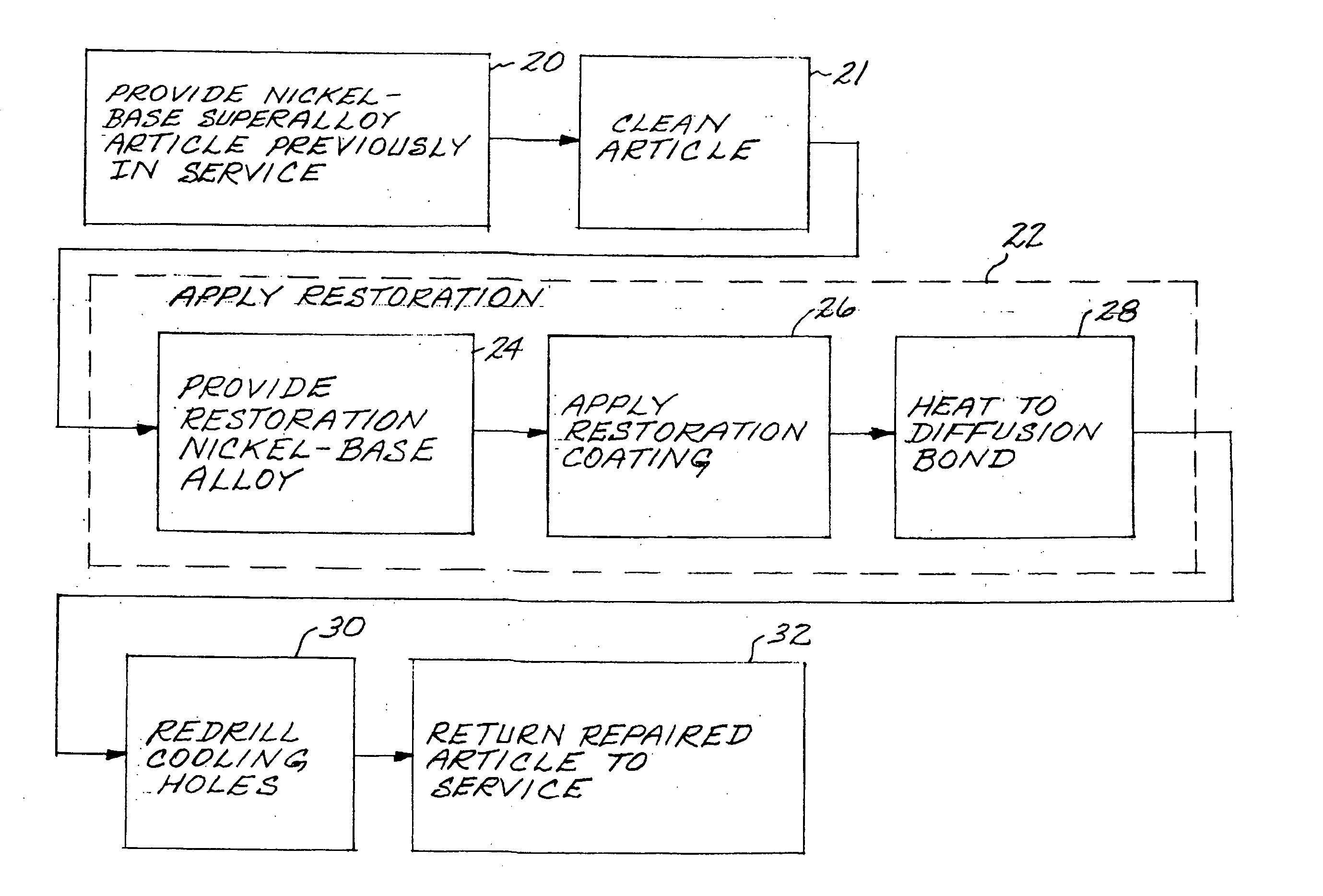

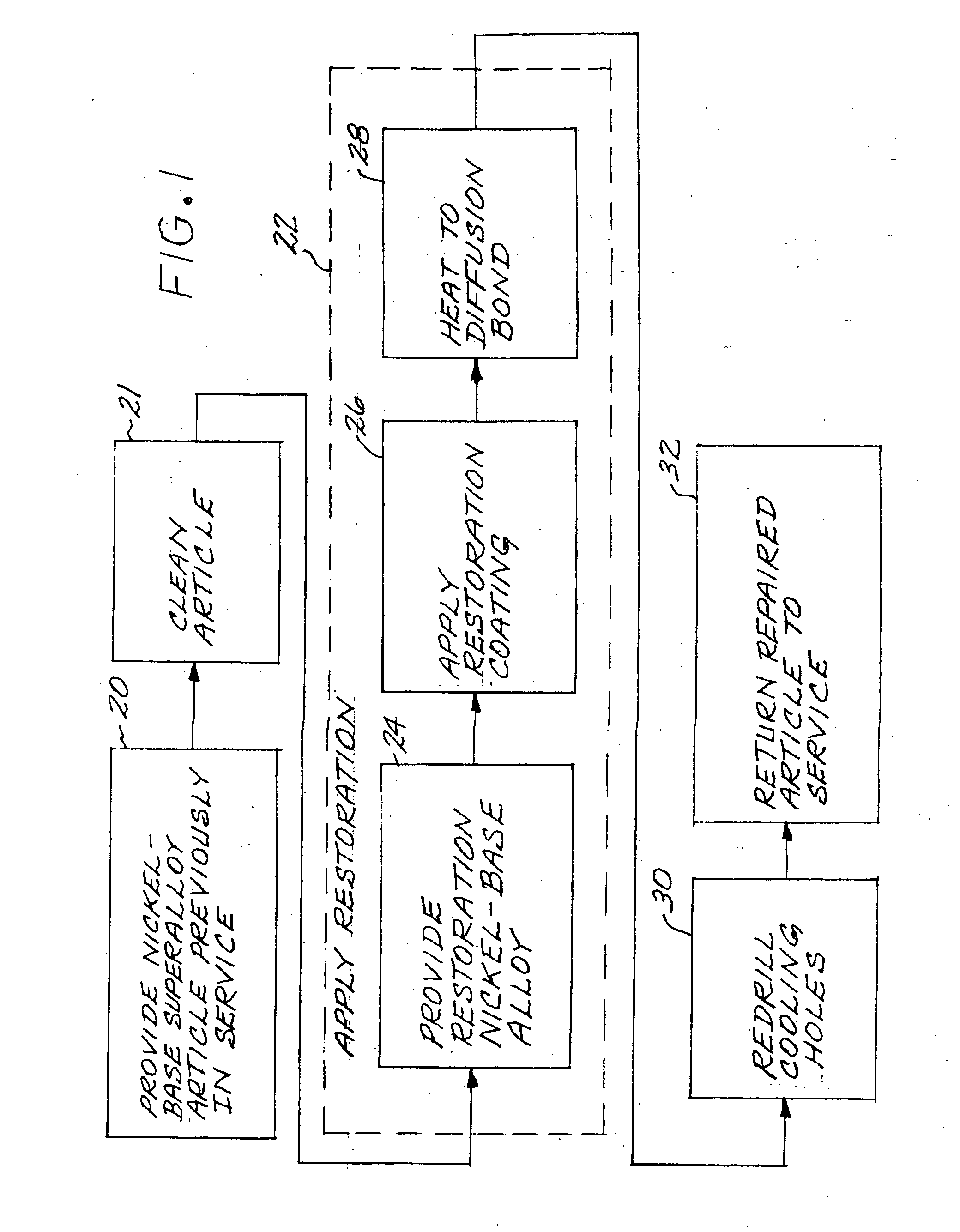

[0022]FIG. 1 depicts in block diagram form a preferred embodiment of a method for repairing a nickel-base superalloy article. In practicing the method, the nickel-base superalloy article that has previously been in service is provided, step 20. The present approach is applicable to any operable article. FIGS. 2-7 depict the use of the method in relation to a presently preferred article, a gas turbine stationary flowpath shroud.

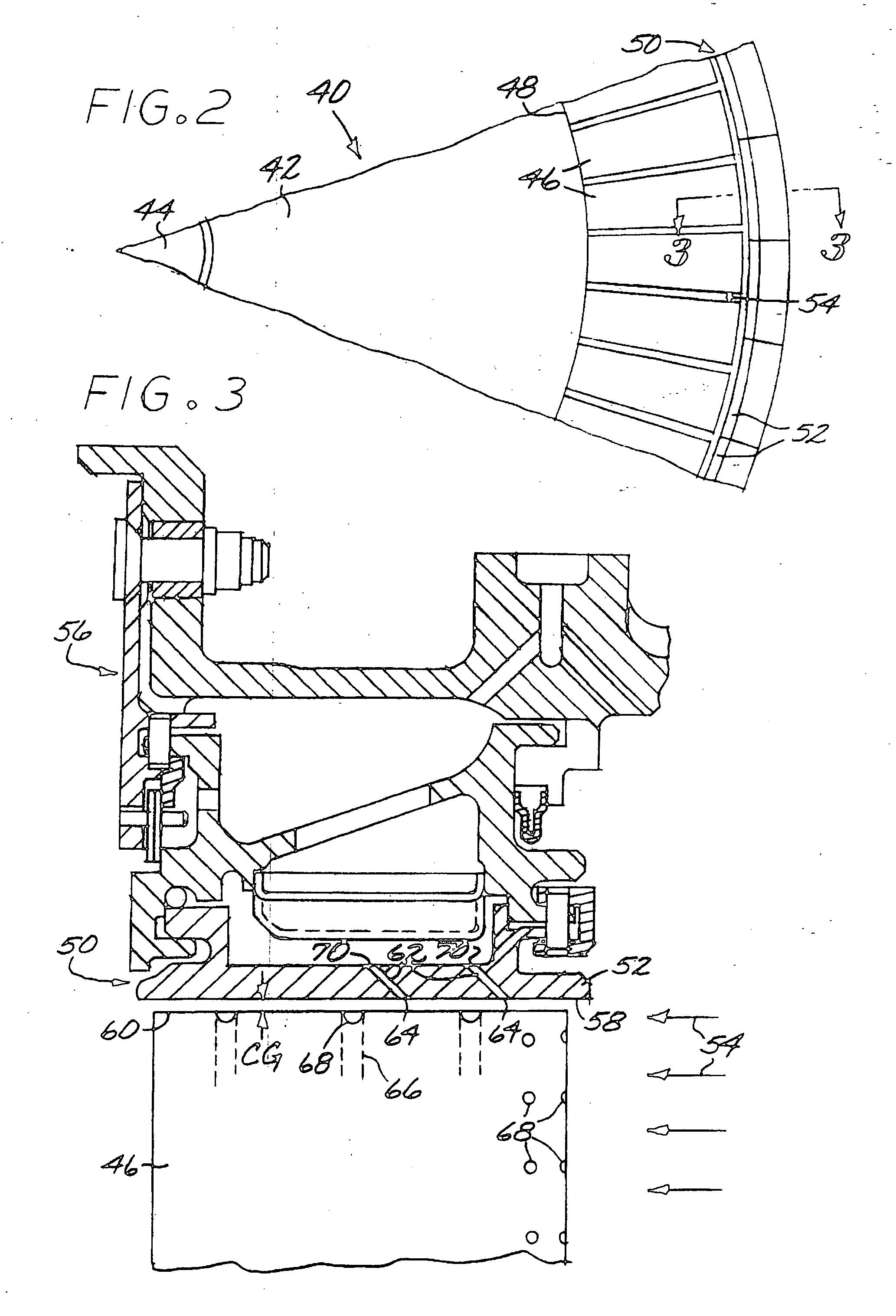

[0023]FIG. 2 presents a simplified depiction of the relevant portions of a gas turbine 40 illustrating only the components of interest. The gas turbine 40 includes a turbine disk 42 that is fixed to and rotates with a center shaft 44. A plurality of turbine blades 46 extend radially outwardly from a periphery 48 of the turbine disk 42. A gas turbine stationary flowpath shroud 50 forms a tunnel-like structure in which the turbine disk 42, the shaft 44, and the turbine blades 46 turn. (The gas turbine stationary flowpath shroud 50 is termed “stationary” and doe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com