Aluminium-oxide-supported iron oxides catalyst, preparation method and application thereof to organic wastewater processing

An alumina-loaded, iron-oxide technology, applied in the oxidation water/sewage treatment and other directions, can solve the problems of weak catalyst loading, weak pre-concentration ability of pollutants, serious catalyst agglomeration, etc. The effect of high ozone utilization rate and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

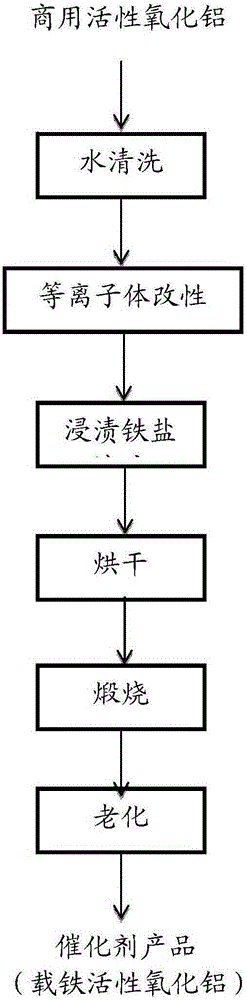

[0043] The first step, carrier modification: take commercial γ-Al with a particle size of 1-3mm 2 o 3 (Pingxiang Xintao Alumina Plant, γ-Al 2 o 3 Porosity: 0.75) particles 100g, washed with tap water, dried at 120°C. Under the working pressure of 25Pa and the RF power of 200W, Ar+O 2 Plasma treatment of activated alumina particles for 3 min.

[0044] The second step, impregnation: impregnate the above-mentioned modified alumina particles in 112.5mL ferric nitrate solution with a mass fraction of 1%, shake in a shaker at 100r / min for 12h, and then put the container into Suspension steaming in a suspension steamer at 60° C. for 12 hours to obtain particles loaded with ferric nitrate.

[0045] The third step, roasting: put the dry alumina particles loaded with ferric nitrate in a box furnace, and roast at 585°C for 2h to obtain the catalyst-iron-loaded activated alumina (FeO x / Al 2 o 3 , x=0-1.5).

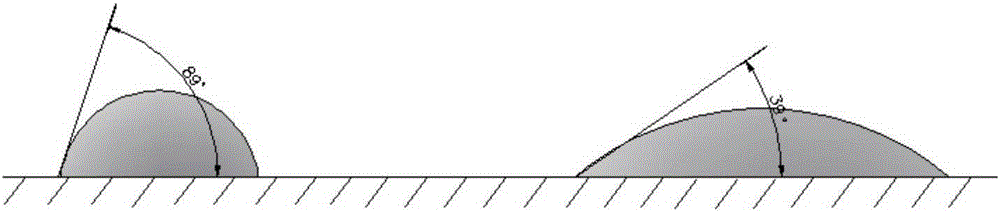

[0046] The pore size, specific surface area, dispersion, and contact an...

Embodiment 2

[0052] The first step, carrier modification: take commercial γ-Al with a particle size of 3-5mm 2 o 3 (Pingxiang Xintao Alumina Plant, γ-Al 2 o 3 Porosity: 0.78) Granules 3kg, washed with tap water, dried at 120°C. Under the working pressure of 25Pa and the RF power of 200W, use N 2 Plasma treatment of activated alumina particles for 3 min.

[0053] The second step, impregnation: impregnate the above-mentioned modified alumina particles in 2.808L of a 2% mass fraction of ferric nitrate and ferric chloride mixed in a solution of 1:3, in a stirring tank at 500r / min The mixture was stirred for 12 hours, and then the alumina particles were dried in an oven at 100° C. for 4 hours to obtain particles loaded with ferric nitrate and ferric chloride.

[0054] The third step, roasting: put the dry particles loaded with ferric nitrate and ferric chloride in a well-type furnace, and roast at 526 ° C for 1.3 h to obtain the catalyst-iron-loaded activated alumina (FeO x / Al 2 o 3 x=...

Embodiment 3

[0061] The first step, carrier modification: take commercial γ-Al with a particle size of 1-3mm 2 o 3 (Pingxiang Xintao Alumina Plant, γ-Al 2 o 3 Porosity: 0.75) Granules 500kg, washed with tap water, dried at 120°C. Under the working pressure of 25Pa and the RF power of 50W, Ar 2 +O 2 Plasma treatment of activated alumina particles for 4min.

[0062] The second step, impregnation: impregnate the above-mentioned modified alumina particles in 562.5L ferric nitrate, ferric chloride, ferrous nitrate, and ferrous chloride with a mass concentration of 6% according to the ratio of 1:2:3:1 In the mixed solution mixed in proportion, stir and mix in a stirring tank for 12 hours, and then put the iron-loaded alumina particles in an oven at 95° C. for 6 hours.

[0063] The third step, roasting: put the dried alumina particles loaded with a mixture of ferric nitrate, ferric sulfate, ferrous nitrate and ferrous sulfate in a converter, and roast at 465°C for 2.5h to obtain the catalys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com