Cool wool knitted fabric and processing method thereof

A wool knitted fabric, cool wool knitting technology, applied in knitting, weft knitting, warp knitting and other directions, can solve the problem of unsatisfactory cooling effect of the fabric, improve the efficiency of evaporation speed and heat conduction, easy to absorb sweat, easy to the effect of diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Mercerized wool fibers produced by enzyme treatment (enzyme treatment partially or completely erodes the scale layer on the wool surface)

[0020] 2. Functional processing of wool fiber

[0021] 1. Hydrophilic processing of wool fiber

[0022] The mercerized wool fiber after peeling scale reduction by enzyme treatment was subjected to low-pressure plasma treatment (argon plasma gas pressure was 50Pa, glow discharge power was 45W, and the treatment time was 10min). After low-pressure plasma treatment, the wool fiber surface The appearance of nano-scale pits increases the number of hydrophilic groups on the surface of the wool fiber, making it super hydrophilic.

[0023] 2. Hydrophobic processing of wool fiber

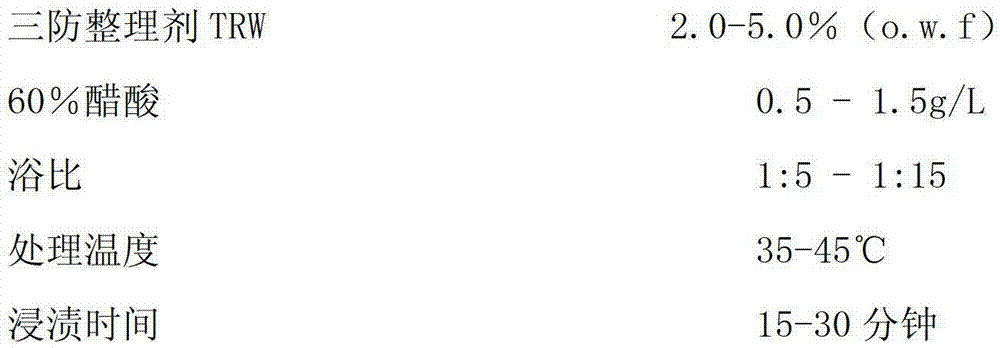

[0024] Treat the mercerized wool fiber after enzymatic treatment and scale reduction with the three-proof finishing agent TRW to make it hydrophobic:

[0025] Tri-proof finishing agent TRW (Shanghai Lansong Industry and Trade Co., Ltd.) ...

Embodiment 2

[0037] 1. Wool fiber

[0038] Mercerized Wool Fiber Produced by Enzyme Treatment

[0039] 2. Functional processing of wool fiber

[0040] 1. Hydrophilic processing of wool fiber

[0041] The mercerized wool fiber was subjected to low-pressure plasma treatment (argon plasma gas pressure was 60Pa, glow discharge power was 50W, and the treatment time was 10min). The number of hydrophilic groups on the surface of wool fiber makes it super hydrophilic.

[0042] 2. Hydrophobic processing of wool fiber

[0043] Treat the mercerized wool fiber after enzymatic treatment and scale reduction with the three-proof finishing agent TRW to make it hydrophobic:

[0044] Tri-proof finishing agent TRW (Shanghai Lansong Industry and Trade Co., Ltd.) 3.5% (o.w.f)

[0045]

[0046] The treated wool fibers were dehydrated and then dried at 150°C for 3 minutes.

[0047] 3. Blended yarn and fabric structure

[0048] The blending ratio of hydrophilic wool fiber and hydrophobic wool fiber is 2...

Embodiment 3

[0056] 1. Wool fiber

[0057] Mercerized Wool Fiber Produced by Enzyme Treatment

[0058] 2. Functional processing of wool fiber

[0059] 1. Hydrophilic processing of wool fiber

[0060] The mercerized wool fiber was treated with low-pressure plasma (argon plasma gas pressure was 70Pa, glow discharge power was 55W, and the treatment time was 5min). After low-pressure plasma treatment, the surface of the wool fiber showed nanoscale pits, increasing The number of hydrophilic groups on the surface of wool fiber makes it super hydrophilic.

[0061] 2. Hydrophobic processing of wool fiber

[0062] Treat the mercerized wool fiber after enzymatic treatment and scale reduction with the three-proof finishing agent TRW to make it hydrophobic:

[0063] Tri-proof finishing agent TRW (Shanghai Lansong Industry and Trade Co., Ltd.) 5.0% (o.w.f)

[0064]

[0065] The treated wool fibers were dehydrated and then dried at 160°C for 1 min.

[0066] 3. Blended yarn and fabric structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com