Low temperature plasma terylene dyeing method

A technology of low-temperature plasma and dyeing method, which is applied in dyeing method, textile and papermaking, ultrasonic/sonic fiber treatment, etc., can solve problems such as polyester system research, achieve the effect of widening the limit and obvious dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Pulsed air atmospheric pressure plasma treatment of polyester fabric, treatment conditions: pulsed air atmospheric pressure plasma treatment power 300W, treatment time 2min, treatment distance 2mm conditions.

[0021] 2) Use cationic Omi Red X-GRL (C.I.Basic Red 46) 2% (to the weight of the fabric), leveling agent TAN 0.5%, adjust the pH of the dye solution to 3.5-4.5 with a mixture of HAc and NaAc, and the bath ratio is 1:50 , temperature 98 ℃, dyeing time 60min. After washing, tumble dry.

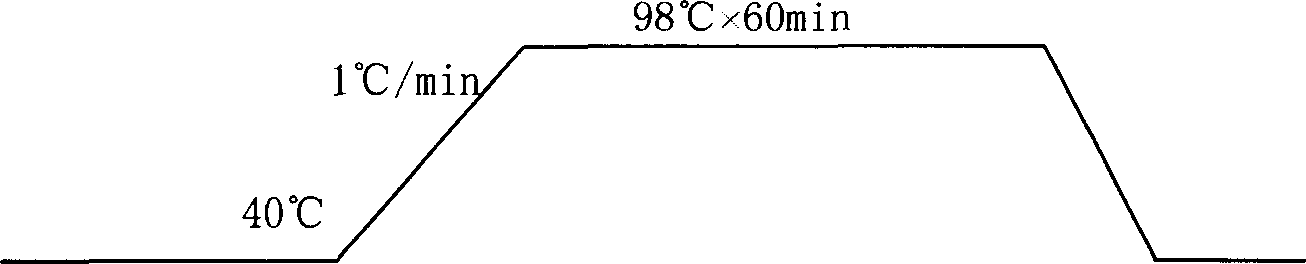

[0022] 3) Dyeing process curve:

[0023]

[0024] 4) The staining results are shown in Table 1

[0025] dye

Embodiment 2

[0027] 1) Pulsed air atmospheric pressure plasma treatment of polyester fabric, processing conditions: pulsed air atmospheric pressure plasma treatment power 150W, treatment time 3min, treatment distance 2mm, polyester fabric was treated.

[0028] 2) Use cationic Omi Blue X-BL (C.I.Basic Blue 66) 2% (to fabric weight), leveling agent TAN 0.5%, adjust the pH of the dye solution to 3.5-4.5 with a mixture of HAc and NaAc, and a bath ratio of 1:50 , temperature 98 ℃, dyeing time 60min. After washing, tumble dry.

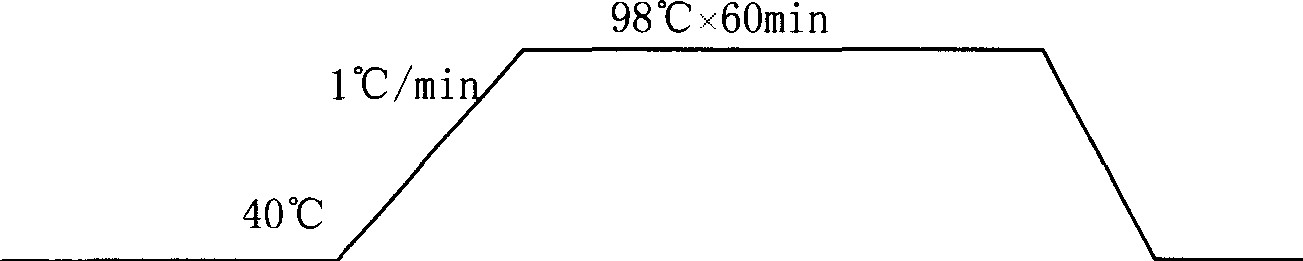

[0029] 3) Dyeing process curve:

[0030]

[0031] 4) The staining results are shown in Table 2

[0032] dye

Embodiment 3

[0034] 1) Pulse low-pressure plasma treatment of polyester fabric. Treatment conditions: power 60W, treatment time 5min, vacuum degree 40Pa.

[0035] 2) Use cationic Omi Yellow X-GL (C.I.Basic Yellow 28) 2% (to fabric weight), leveling agent TAN 0.5%, adjust the dyeing solution to pH 3.5-4.5 with HAc and NaAc mixture, bath ratio 1: 50. The temperature is 98°C, and the dyeing time is 60 minutes. After washing, tumble dry.

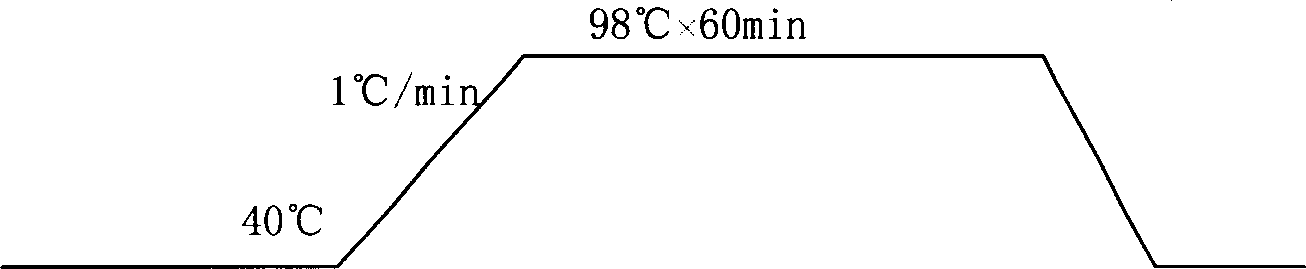

[0036] 3) Dyeing process curve:

[0037]

[0038] 4) The staining results are shown in Table 3

[0039] dye

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com