Manufacturing method of titanium copper compound pot

A production method and technology of composite pots, which are applied in application, coating, kitchen utensils, etc., can solve the problems of poor thermal conductivity of titanium, and achieve the effects of strong titanium rigidity, concentrated heat source, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

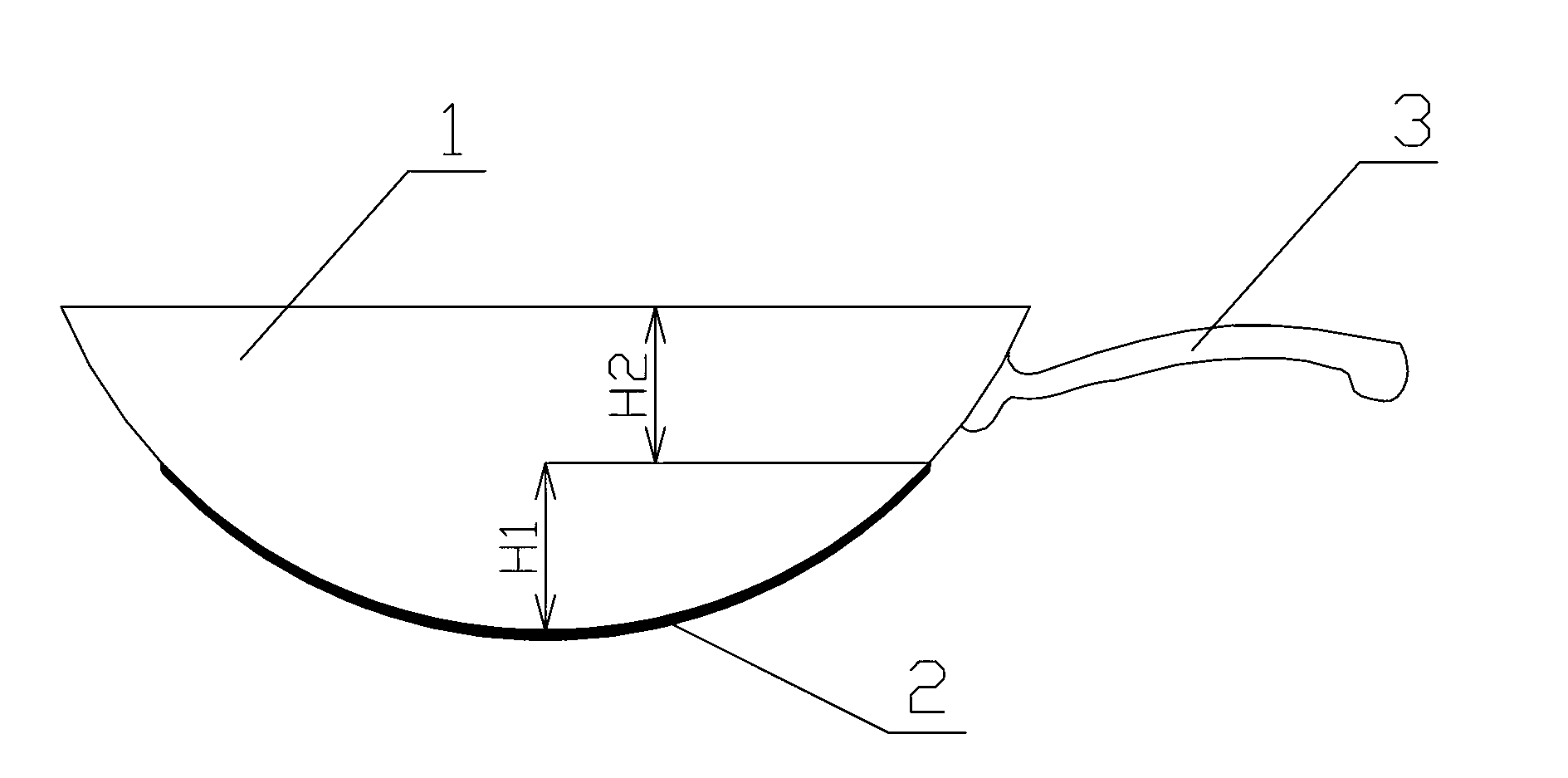

[0038] The structure of the titanium-copper composite pot that present embodiment makes is as follows figure 1 As shown, its production method is:

[0039] Step 1. Polish the surface of a pure titanium plate with a thickness of 3mm, and then punch the polished titanium plate to form a pot body 1, and use a conventional metal cleaning agent (purchased from Feitian, Longcheng Chemical Factory, Yantan District, Zigong City, Sichuan Province brand 702 metal cleaning agent) to clean and degrease the pot body 1;

[0040] Step 2. Sandblasting the lower part of the outer surface of the pot body 1 after cleaning and degreasing in step 1 to remove the surface scale, and then paint the outer surface of the pot body 1 and the inner surface of the pot body 1 Conventional insulating glue (purchased from Xi'an Guoyuze Chemical Technology Co., Ltd. S-1 electroplating special peelable protective coating) for insulation protection; The outer surface of the pot body 1, wherein the ratio of the...

Embodiment 2

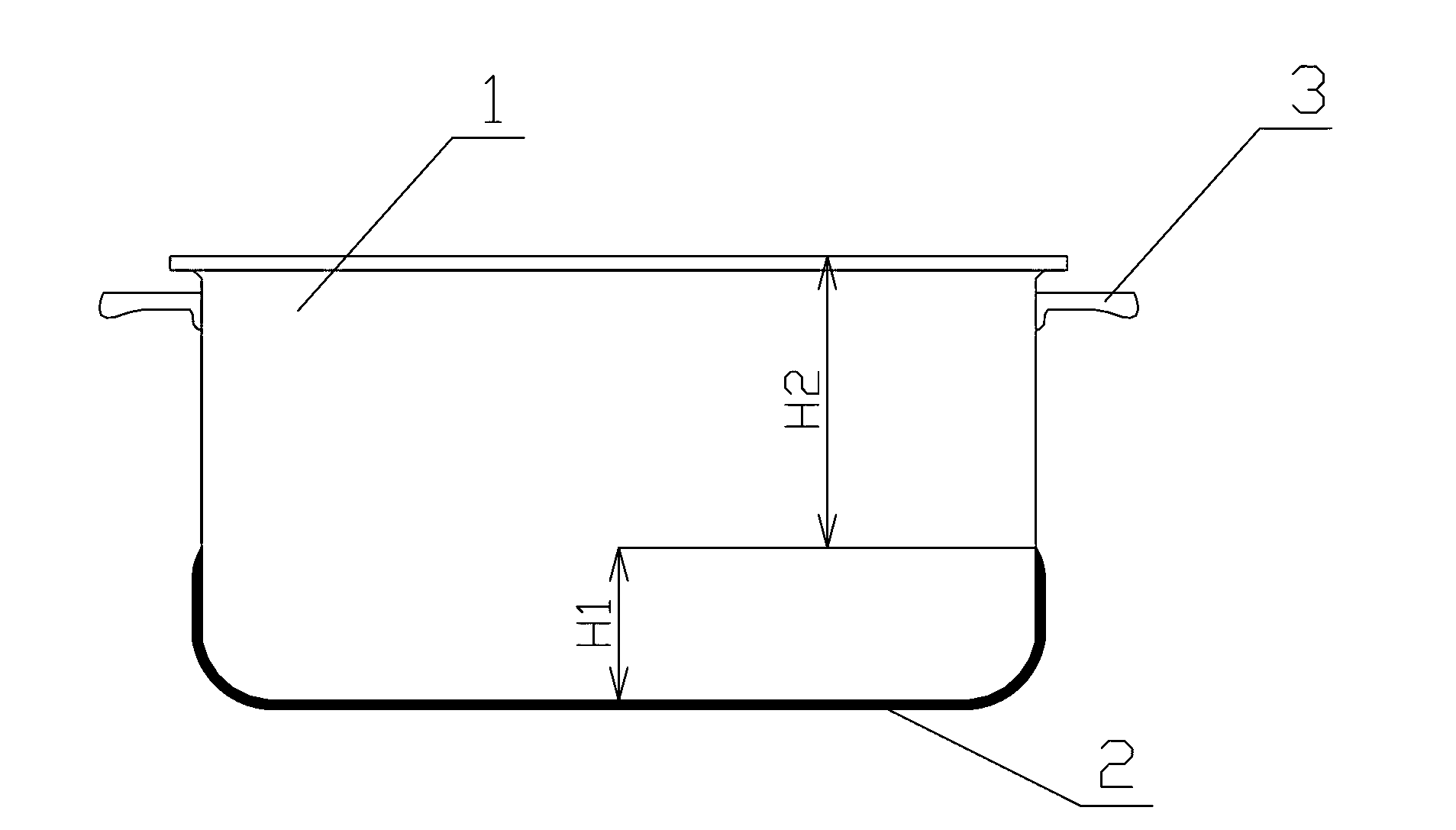

[0048] The structure of the titanium-copper composite pot that present embodiment makes is as follows figure 2 As shown, its production method is:

[0049] Step 1. Polish the surface of a pure titanium plate with a thickness of 2 mm, and then stamp the polished pure titanium plate to form a pot body 1. Use a conventional metal cleaning agent (purchased from Shanghai Arrow Chemical Co., Ltd. 664 metal cleaning agent) to clean the pot body. Body 1 is cleaned and degreased;

[0050] Step 2. Sandblasting the lower part of the outer surface of the pot body 1 after cleaning and degreasing in step 1 to remove the surface scale, and then paint the outer surface of the pot body 1 and the inner surface of the pot body 1 Conventional insulating glue (plastic electroplating insulating oil 9901) for insulation protection; the lower part of the outer surface of the pot body 1 and the upper part of the outer surface of the pot body 1 constitute the outer surface of the entire pot body 1, w...

Embodiment 3

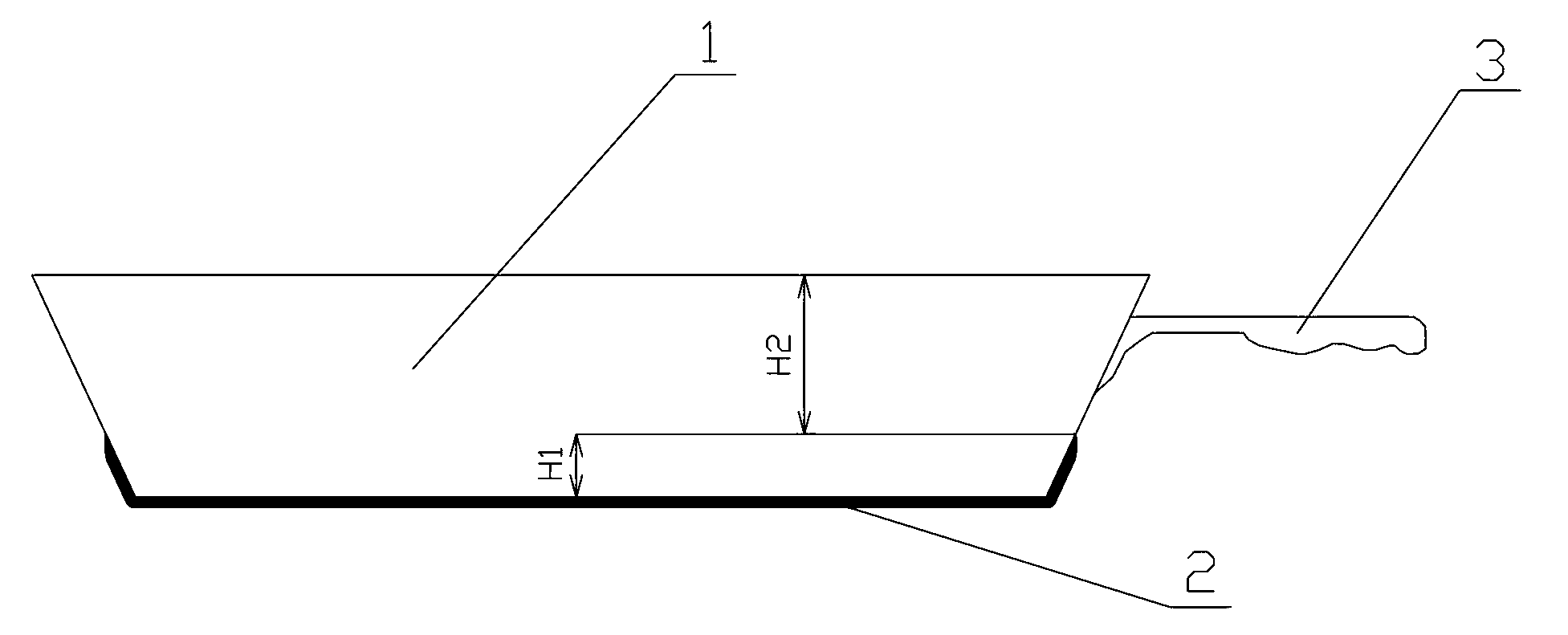

[0058] The structure of the titanium-copper composite pot that present embodiment makes is as follows image 3 As shown, its production method is:

[0059] Step 1. Polish the surface of a pure titanium plate with a thickness of 1mm, and then punch the polished titanium plate to form a pot body 1, and use a conventional metal cleaning agent (purchased from Feitian, Longcheng Chemical Factory, Yantan District, Zigong City, Sichuan Province brand 702 metal cleaning agent) to clean and degrease the pot body 1;

[0060] Step 2. Sandblasting the lower part of the outer surface of the pot body 1 after cleaning and degreasing in step 1 to remove the surface scale, and then paint the outer surface of the pot body 1 and the inner surface of the pot body 1 Conventional insulating glue (purchased from Xi'an Guoyuze Chemical Technology Co., Ltd. S-1 electroplating special peelable protective coating) for insulation protection; The outer surface of the pot body 1, wherein the ratio of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com