Method for preparing aluminum-nitrogen co-doped diamond-like-like composite film

A composite film and diamond technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve problems such as rare research, achieve the effect of reducing roughness, reducing internal stress, and improving surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

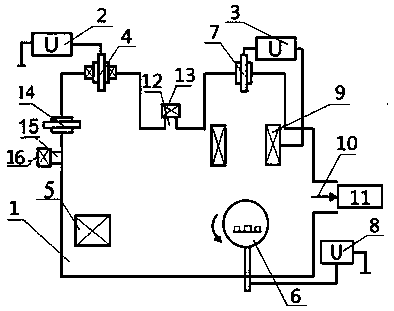

[0033]At first provide a kind of coating device that adopts in the substrate surface modification process, promptly described direct current and pulse dual excitation source cathodic arc coating device, such as figure 1 As shown, the device includes a vacuum chamber 1, a DC aluminum cathode target 4, and a pulsed graphite cathode target 7; a DC aluminum cathode arc power supply 2 and a pulsed graphite cathode arc power supply 3 are installed on the rear wall of the vacuum chamber 1, and the DC aluminum cathode target 4 is equipped with The upper and lower sets of combined deflection magnetic filter devices 5, the bottom of the vacuum chamber 1 is equipped with a circular rotating sample stage 6, and the lower end of the sample stage is connected to a bias power supply 8 outside the vacuum chamber; a pulsed graphite anode target is arranged below the pulsed graphite cathode target 7 9. There is a sputtering ion source 14 under the DC aluminum cathode target; an exhaust channel 1...

Embodiment 2

[0040] This embodiment provides a method for preparing a high-hardness, high-toughness aluminum-nitrogen co-doped diamond-like composite film using the device described in Embodiment 1, comprising the following steps:

[0041] (1) Workpiece surface treatment: put the workpiece into acetone solution, ethanol solution and deionized water for 10 minutes to ultrasonically clean each to remove surface grease and other pollutants, and then place the substrate in an oven to dry for use;

[0042] (2) Fix the pretreated workpiece in such as figure 1 On the rotary sample stage 6 in the vacuum chamber 1 of the cathodic arc device shown, the DC aluminum cathode target 4 and the pulse graphite cathode target 7 are installed on the evaporators of the DC aluminum cathode arc power supply 2 and the pulse cathode arc power supply 3 respectively;

[0043] (3) Vacuumize the vacuum chamber 1 with a vacuum device 11 to make the vacuum degree reach 6×10 −4 Pa; Pass argon gas into the vacuum chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Residual stress | aaaaa | aaaaa |

| Nanohardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com