A barrel-shaped laminated pressure-resistant device for deep-sea diving and its forming process

A pressure-resistant device and barrel-shaped technology, which is applied to underwater ships, transportation and packaging, special-purpose ships, etc., can solve the problems that the mechanical properties of materials are not fully utilized, the stress cannot be effectively released, and the welding residual stress is large. The effect of reducing initial geometric defects, reducing design difficulty, and releasing welding residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

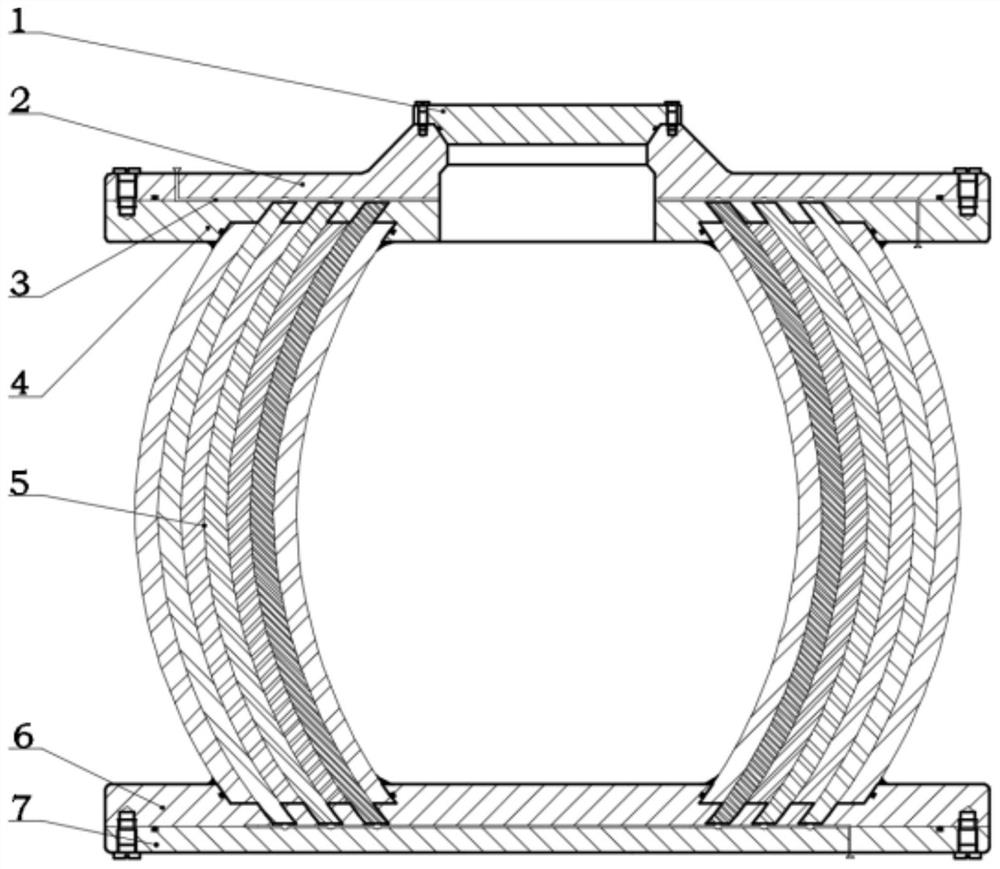

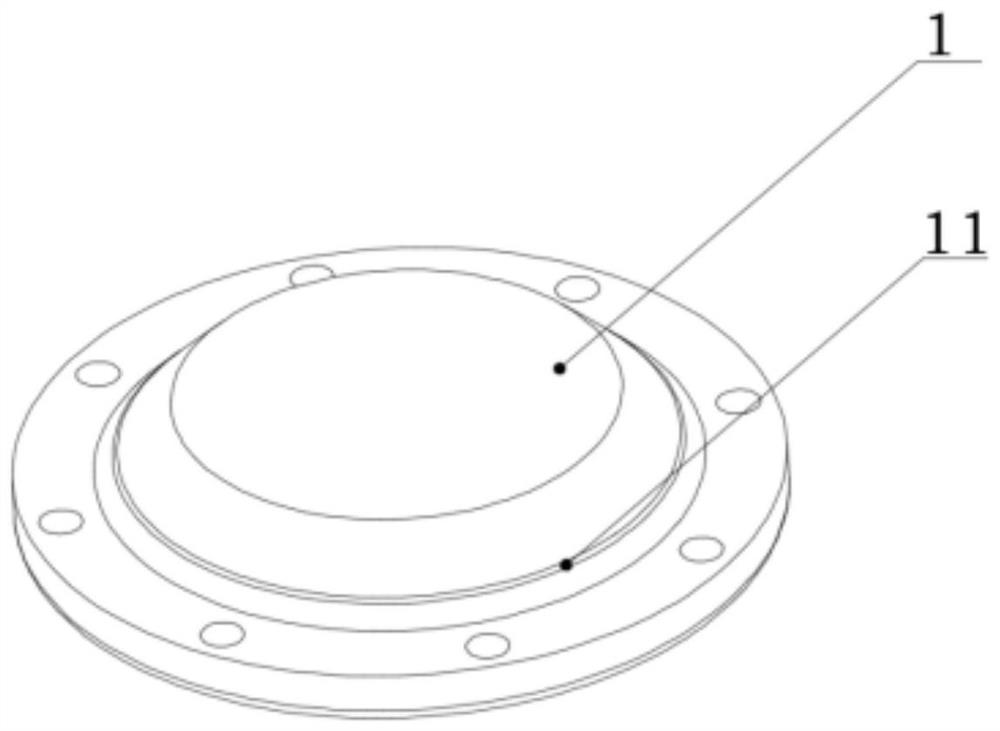

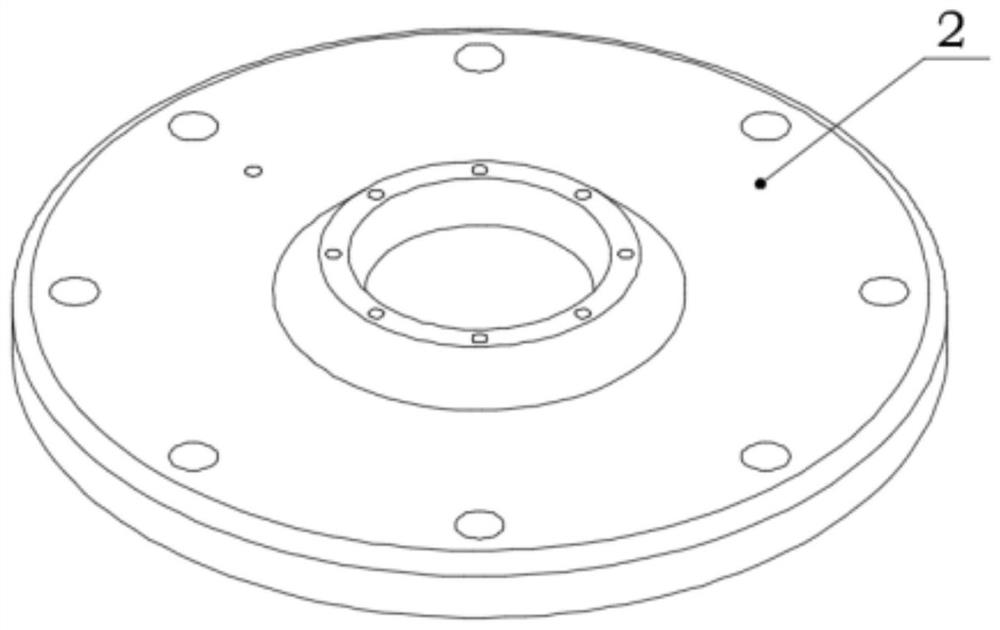

[0047] Such as figure 1 A barrel-shaped pressure-resistant shell device is shown, from top to bottom, the upper end cover cap 1, the upper end connection cover 2, the upper end connection cover oil circuit 3, the upper end slot cover 4, and the barrel-shaped laminated pressure shell 5 , the lower card slot cover 6 and the lower card plate cover 7 are connected to form. Wherein the upper end cover block cap 1 and the upper end connection cover 2 are matched with the connection cover groove by the block boss and connected by screws. The upper slot cover 4 is connected under the upper connection cover 2 by screws, and the barrel-shaped laminated pressure-resistant shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com