Method and apparatus for stimulating a subterranean formation using liquefied natural gas

a technology of liquefied natural gas and subterranean formation, which is applied in the direction of fluid removal, borehole/well accessories, survey, etc., can solve the problems of difficult and expensive acquisition of water required for these fluids, environmental protection, and difficulty in obtaining water, so as to reduce the time to production, the effect of reasonable cost and desirable and lasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

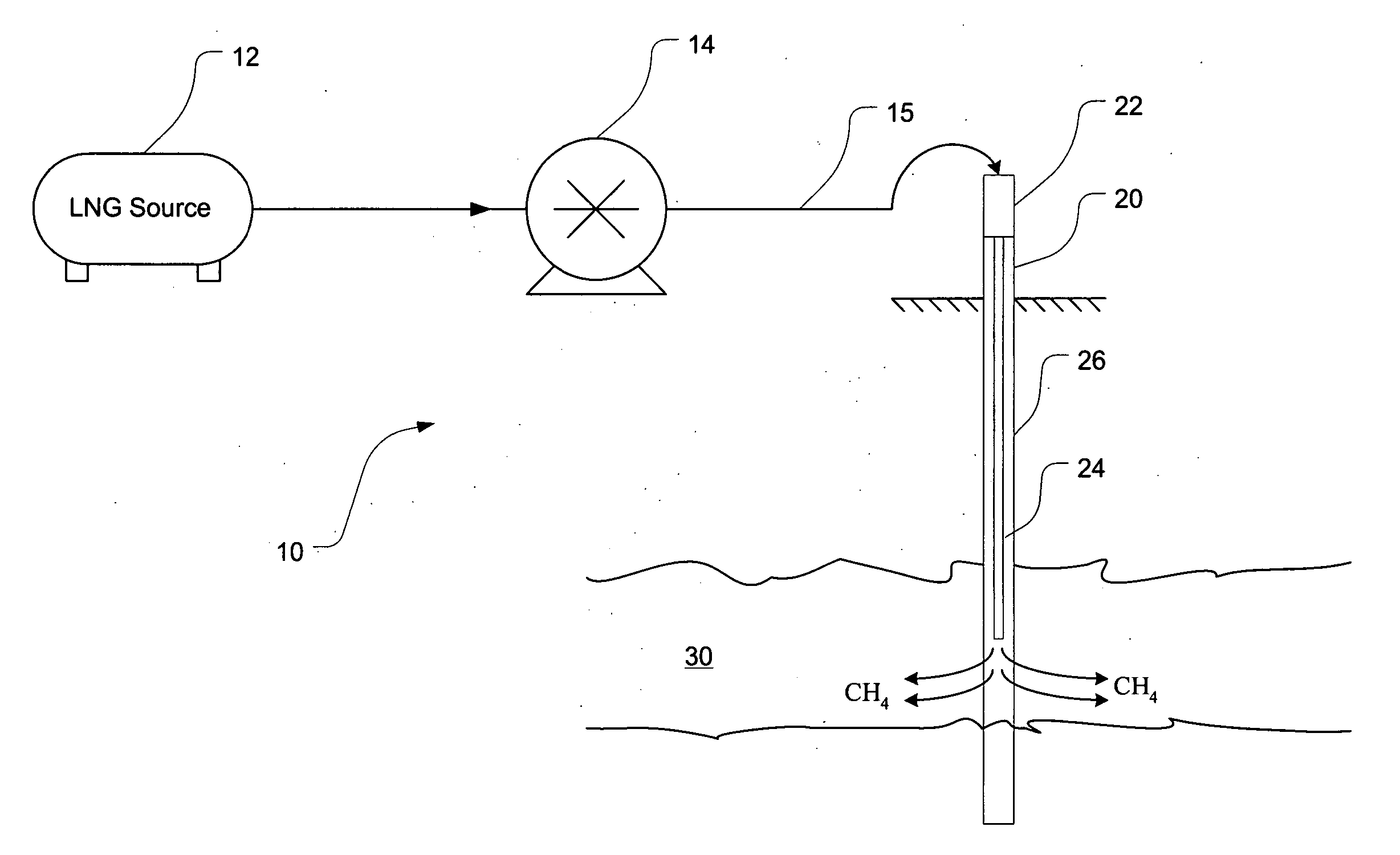

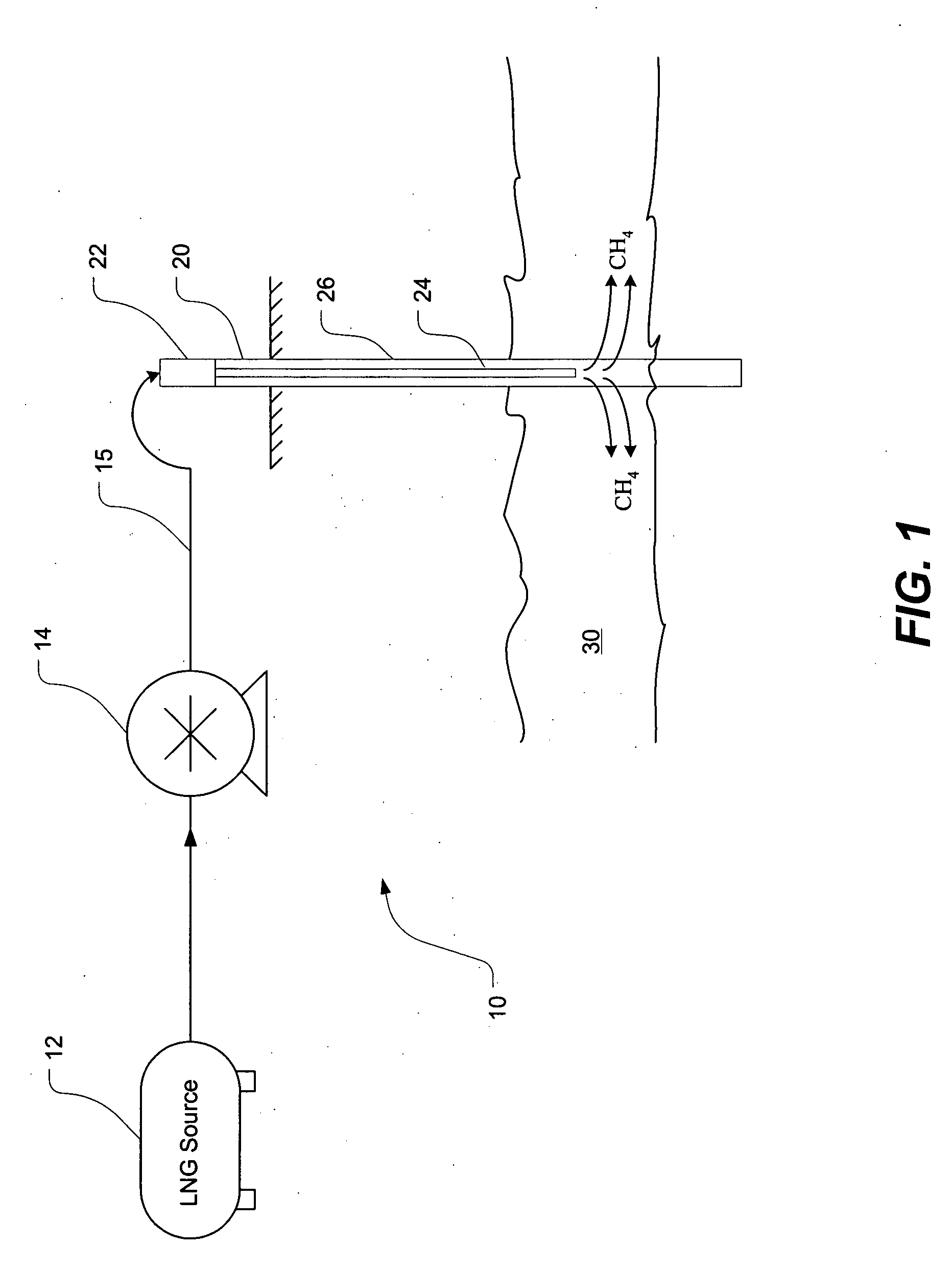

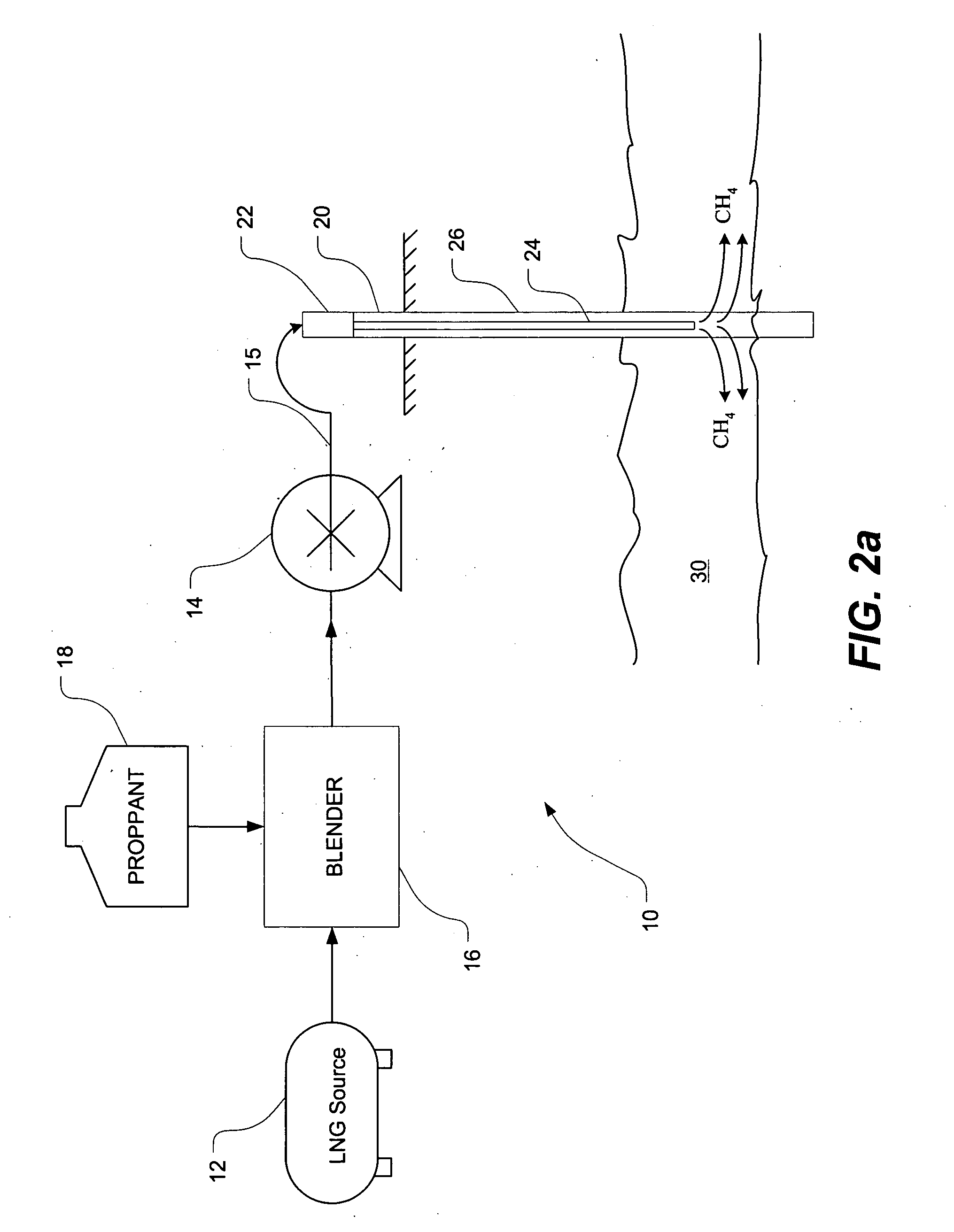

[0030] In general, and as will be explained below in detail, the invention provides a method and system for fracturing a subterranean formation using liquefied natural gas (LNG) or liquefied methane, hereinafter referred to collectively as liquefied natural gas. The liquefied natural gas is pumped as a cryogenic fluid at pressures and flow rates that are high enough, to fracture the subterranean formation requiring stimulation. After fracturing operations are complete, the natural gas used as fracturing fluid can be recovered and commercialized without loss or damage to the environment, rendering this method of fracturing highly economical and environmentally sound. The LNG can be blended with proppants before or after pumping and is optionally heated either before it enters the well or during descent through the well bore.

[0031] As used in this disclosure, “liquefied natural gas” means liquefied methane and blends of liquefied methane (CH4) with any other normally gaseous hydrocar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com