Construction process of environment-friendly organic aluminized chromium slurry

A construction technology and environment-friendly technology, applied in the field of aluminized chromium, can solve the problems of difficult seepage prevention, dust hazards, etc., and achieve the effects of protecting health, ensuring quality, and reducing foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

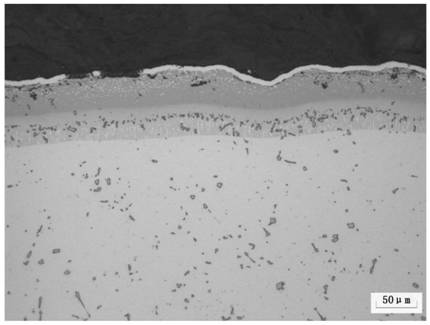

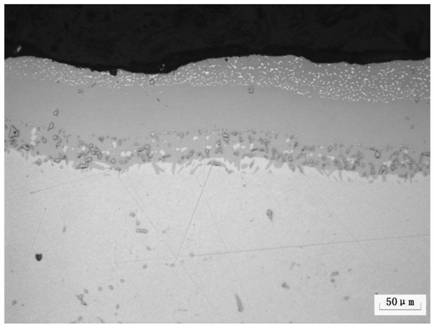

Image

Examples

Embodiment 1

[0054] The construction technology of environment-friendly organic aluminized chromium slurry is used to form an aluminized chromium coating on turbine working blades, including the following steps:

[0055] S1. Mix aluminum powder, chromium powder, ethanol, polyvinyl alcohol and water in a mass fraction ratio of 40%: 20%: 10%: 4%: 26%, and grind them in a ball mill for ≥ 20 hours to obtain an organic aluminized chromium material pulp, spare;

[0056] S2. Use aviation washing gasoline to clean the workpiece, dry in an oven at 80°C for 30 minutes, heat up to 400°C, dry for 30 minutes, and protect the non-permeable layer with adhesive tape after cooling;

[0057] S3. Perform corundum sand blowing treatment on the surface to be infiltrated. The particle size of the corundum sand is 240 mesh and the pressure is 0.2 MPa. Sand blowing until the surface to be infiltrated is uniform gray-white, and the interval between sand blowing and spraying shall not exceed 4 hours;

[0058] S4. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com