Automotive pattern nut and forming method thereof

A pattern and nut technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of low yield and short service life of molds, and achieve the effect of improving service life, increasing mold life, and reducing folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

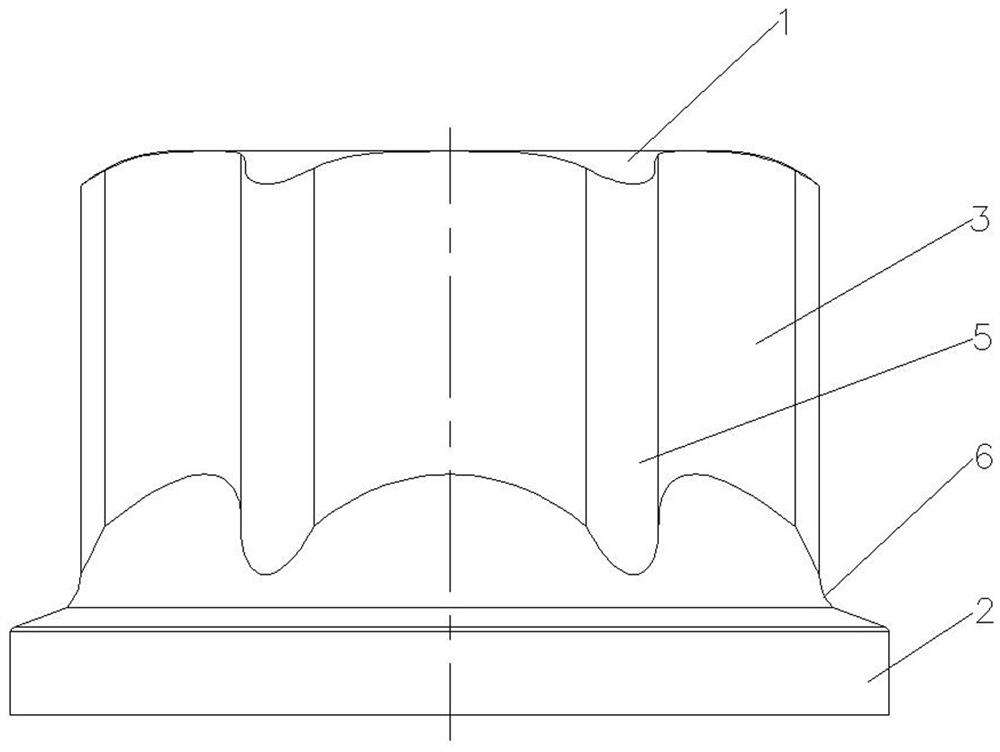

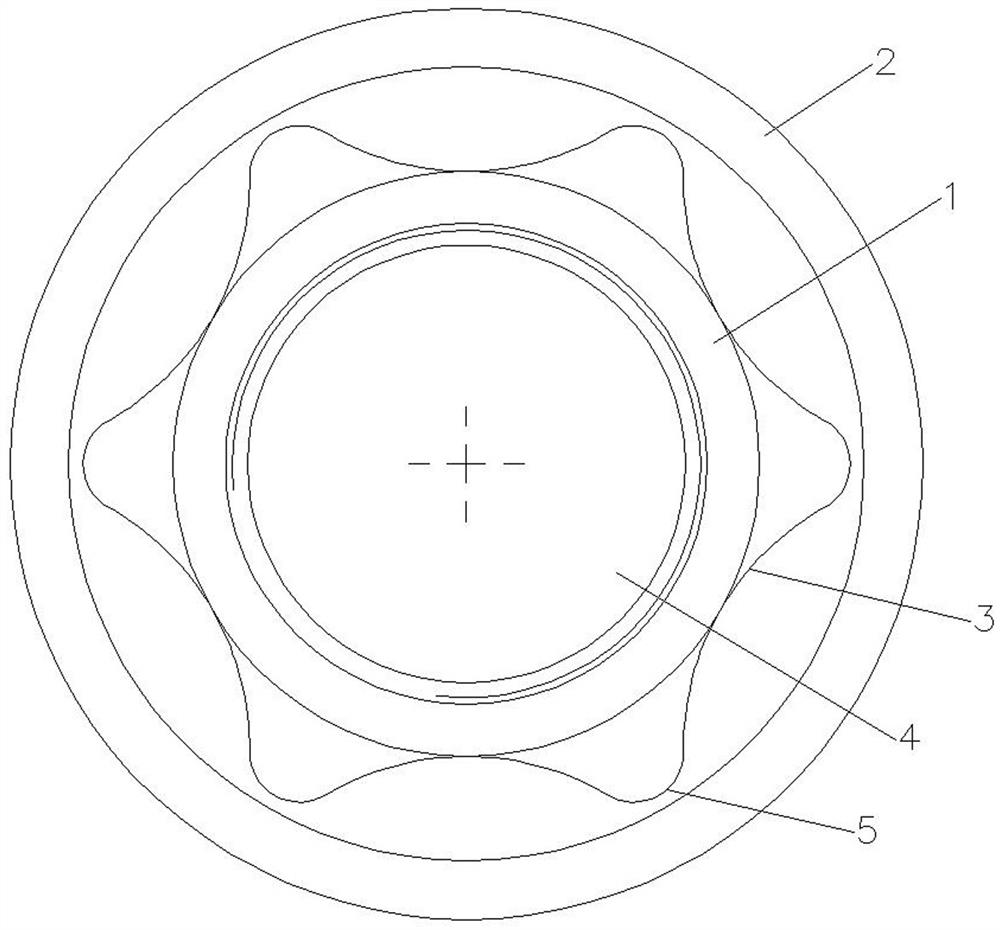

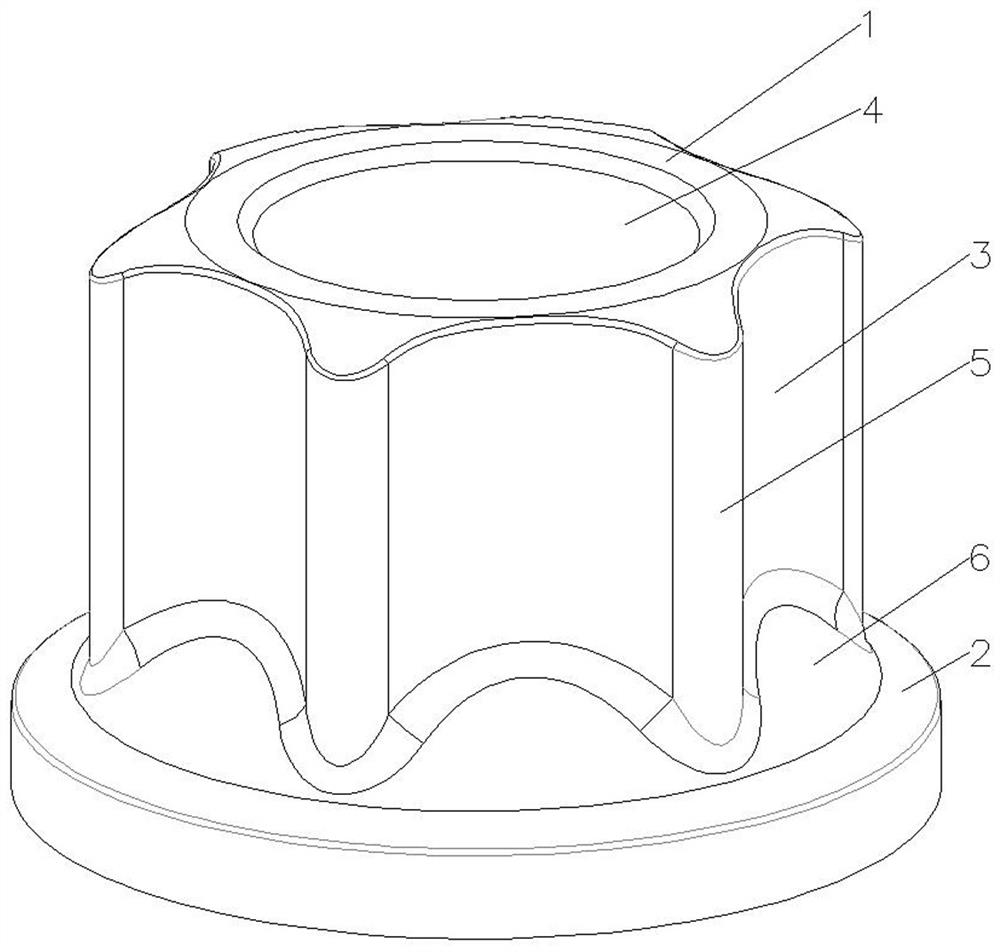

[0021] Such as figure 1 , figure 2 with image 3 As shown, a flower nut for vehicles includes an integral structure composed of a main body 1 and a flange part 2. The main body has six sides 3 in total. The sides on the main body are all concave arc-shaped surfaces. The threaded hole 4; the diagonal part 5 of the main body and the transition part 6 between the main body and the flange part are all arc structures, which can increase the structural strength of the nut.

[0022] A method for forming a flower nut for a vehicle, the specific steps are as follows:

[0023] The first step: blanking is a cylindrical blank;

[0024] The second step: Pre-upsetting cylindrical process parts with rounded corners;

[0025] Step 3: Upsetting the flower-shaped main body. The flower-shaped main body has six sides, and the six sides are all concave arc-shaped surfaces. The arc length of each side is 10% smaller than the arc length of the final flower-shaped nut. The arc radius is 48% lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com