Hydrostatic extrusion device for micro planar spring

A planar spring and hydrostatic extrusion technology, which is applied in the field of miniature planar spring preparation, can solve problems such as easy cracking, extrusion rod damage, and part cracks, and achieve uniform force, improved utilization rate, and large extrusion force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

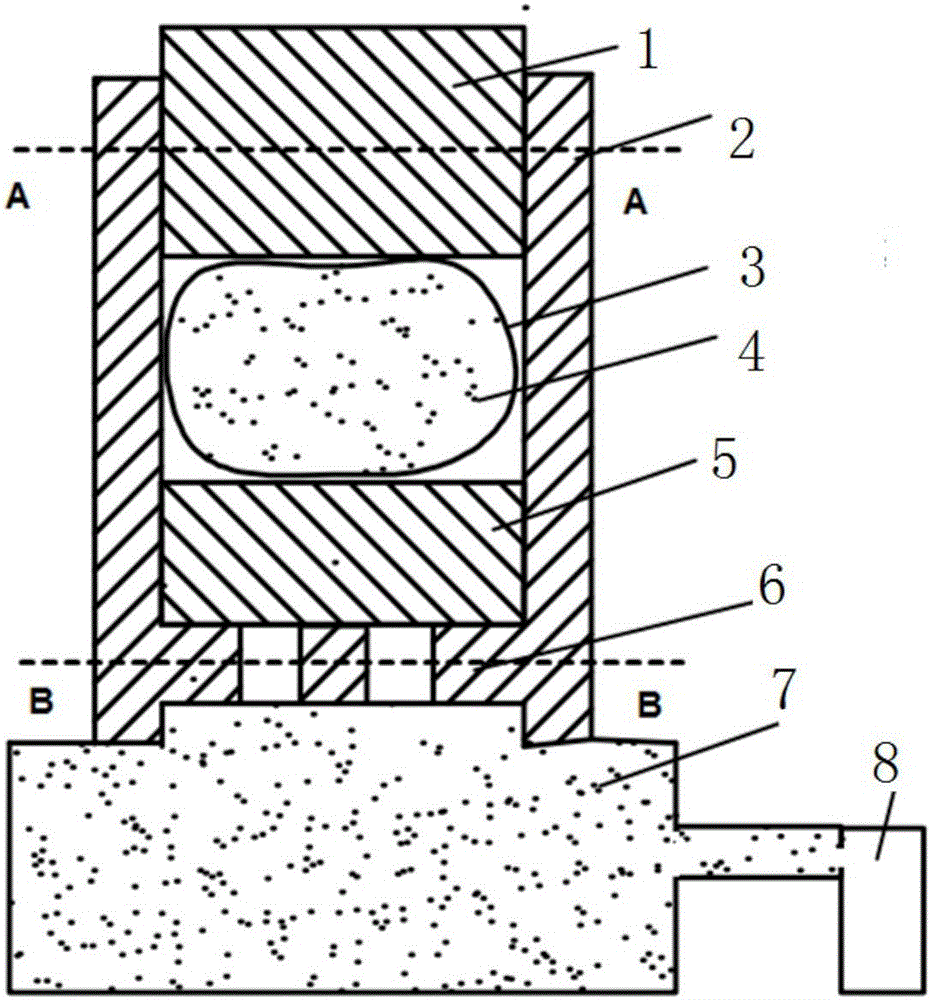

[0033] A QAl7 copper alloy spring column with a length of 4mm, a width of 2mm, and a thickness of 4mm was prepared by hydrostatic extrusion, with a line width of 0.5mm, and the spring column was subsequently cut into a planar microspring with a thickness of 0.5mm.

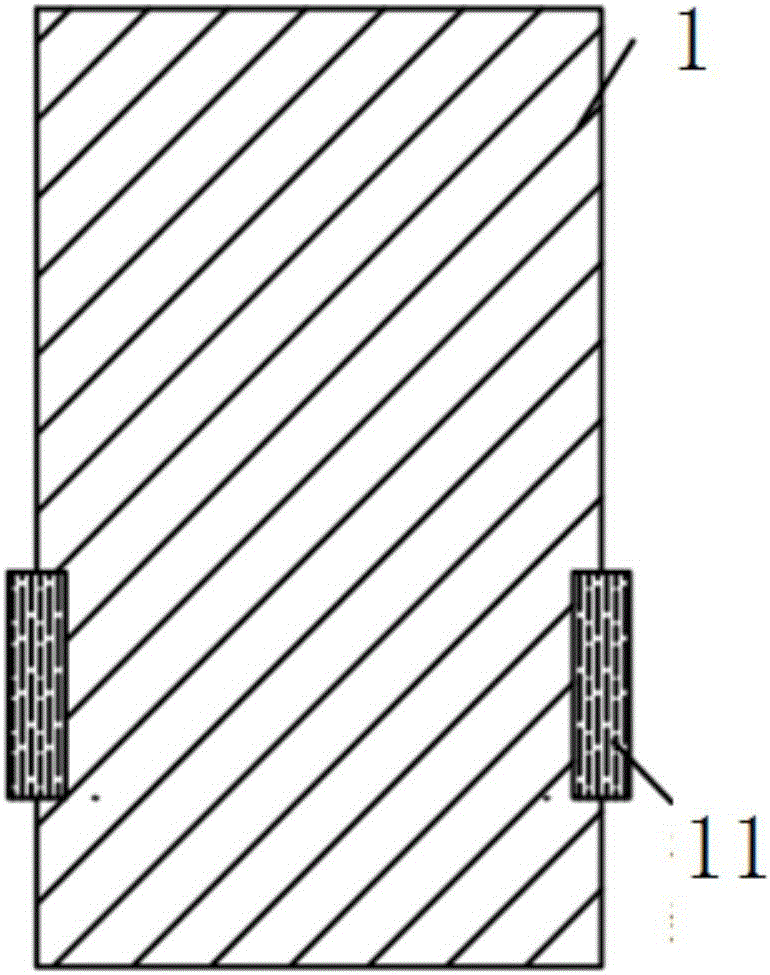

[0034] The extrusion rod 1 has a diameter of 23 mm, and the extrusion rod 1 has a groove with a depth of 1.5 mm and a width of 6 mm.

[0035] Blank 5 size: 4mm×2mm×4mm rectangular block.

[0036] A single wide sealing ring 11 is adopted, the cross section of the sealing ring is rectangular, the inner diameter is 22 mm, the outer diameter is 25 mm, the width is 6 mm, and the thickness is 4 mm.

[0037] Squeeze liquid adopts castor oil, the volume of castor oil is 1600mm 3 , castor oil is wrapped with rubber film 3, castor oil is wrapped with rubber film 3, seals with rope.

[0038] The outlet of the extrusion cylinder is connected to the hydraulic device 8 through a pipeline, and a reverse force is applied to the ...

Embodiment 2

[0046] A QAl7 copper alloy spring column with a length of 40 mm, a width of 1 mm, and a thickness of 6 mm was prepared by hydrostatic extrusion, with a line width of 0.2 mm. The spring column was subsequently cut into a planar microspring with a thickness of 1 mm.

[0047] The inner diameter of the extrusion cylinder 2 is 24mm.

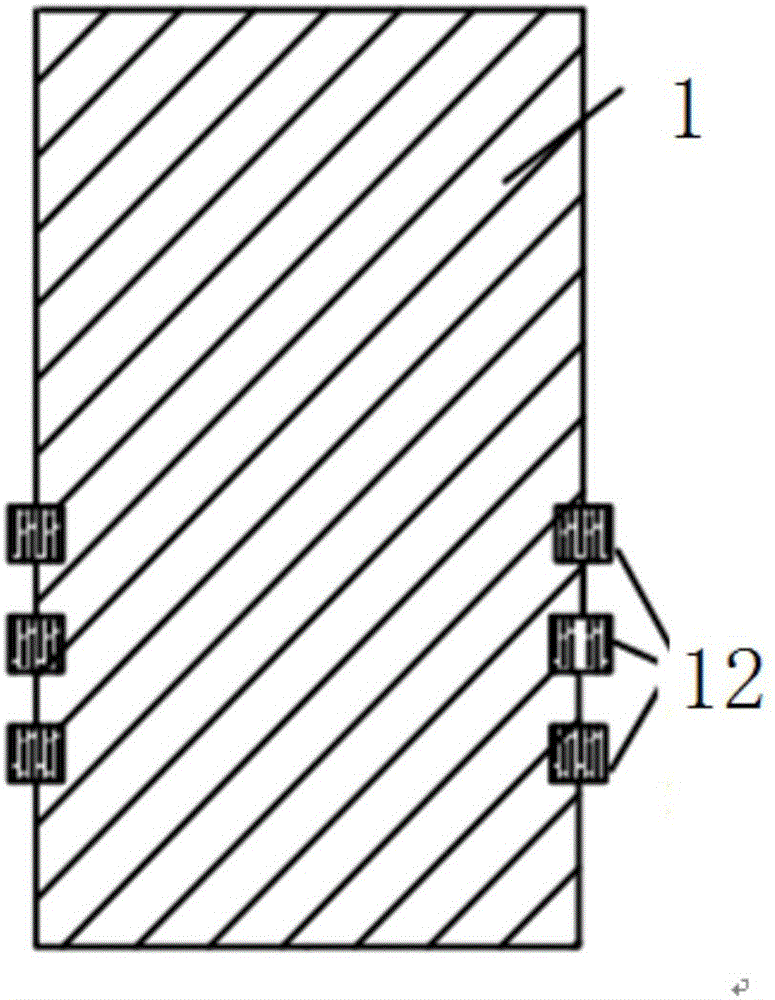

[0048] The extrusion rod 1 has a diameter of 23mm, and there are three grooves on the extrusion rod 1 with a depth of 1.5mm and a width of 2mm, and the distance between the grooves is 2mm.

[0049] Blank 5 size: 40mm×1mm×6mm rectangular block.

[0050] A plurality of narrow sealing rings 12 are adopted, the cross section of the sealing ring is rectangular, the inner diameter is 22 mm, the outer diameter is 25 mm, the width is 2 mm, and the thickness is 3 mm.

[0051]Squeeze liquid adopts castor oil, the volume of castor oil is 1000mm 3 , the castor oil is wrapped with a rubber film 3 and connected with the extrusion rod 1. The specific connection m...

Embodiment 3

[0055] A QAl7 copper alloy spring column with a length of 8 mm, a width of 6 mm, and a thickness of 2 mm was prepared by hydrostatic extrusion, with a line width of 1 mm. The spring column was subsequently cut into a planar microspring with a thickness of 0.5 mm.

[0056] The inner diameter of extrusion barrel 2 transitions from 24mm to 16mm at an angle of 45°, see Figure 5 .

[0057] The extrusion rod 1 has a diameter of 23mm, and there are three grooves on the extrusion rod 1 with a depth of 1.5mm and a width of 2mm, and the distance between the grooves is 2mm.

[0058] Blank 5 size: 8mm×6mm×2mm rectangular block.

[0059] A plurality of narrow sealing rings 12 are adopted, the cross section of the sealing ring is rectangular, the inner diameter is 22 mm, the outer diameter is 25 mm, the width is 2 mm, and the thickness is 3 mm.

[0060] The extrusion liquid adopts castor oil, and the volume of castor oil is 2000mm 3 , the castor oil is wrapped with a rubber film 3 and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com