Method for chemical silver-plating of aramid conductive fibers

A technology of chemical silver plating and conductive fiber, which is applied in the direction of liquid chemical plating, fiber type, fiber treatment, etc. It can solve the problems of affecting the conductivity and durability of fibers, the metal coating is easy to fall off, and the reactivity is low, so as to reduce the process and pollution, excellent plating fastness, high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

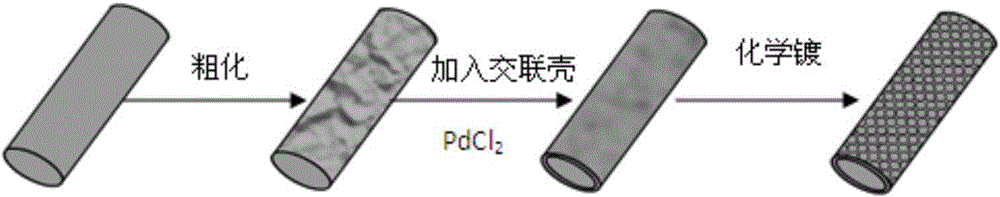

Method used

Image

Examples

Embodiment 1

[0028] (1) Prepare an acidic potassium permanganate solution, containing 3 g of potassium permanganate and 100 g of sulfuric acid per liter of the solution, immerse the aramid fiber, ultrasonically treat it for 40 minutes at 20° C., then take out the fiber, wash it, and dry it.

[0029] (2) dissolving chitosan with the acetic acid solution of 1% with mass fraction, chitosan solution concentration 5g / L, control temperature at 0 ℃, add dropwise 15ml formaldehyde solution with the speed of 10s / drop, stirring process 20 minutes, then Immerse the aramid fibers, raise them to room temperature, pad them with a liquid removal ratio of 60%, and then bake them at 120°C.

[0030] (3) Prepare a 50mg / L palladium chloride solution, immerse the fabric at 40°C for 60 minutes, and dry at 50°C.

[0031] (4) First prepare silver ammonia solution: 10g / L AgNO 3 , add ammonia water dropwise until clarified; then prepare reducing solution: glucose 20g / L, tartaric acid 0.05g / L, ethanol 100mL / L, eth...

Embodiment 2

[0036] (1) Prepare an acidic potassium permanganate solution, containing 8 g of potassium permanganate and 100 g of nitric acid per liter of the solution, immerse the aramid fiber, ultrasonically treat it for 30 minutes at 30° C., then take out the fiber, wash it, and dry it.

[0037] (2) dissolving chitosan with a mass fraction of 2% acetic acid solution, chitosan solution concentration 10g / L, control temperature at 5°C, add 10ml glutaraldehyde solution dropwise at a speed of 10s / drop, and stir for 20 minutes , and then immersed in the aramid fiber, raised to room temperature, padding, the rate of liquid extrusion is 80%, and then baked at 140°C.

[0038] (3) Prepare 80mg / L palladium chloride solution, soak the fabric for 60 minutes at 40°C, and dry at 50°C.

[0039] (4) First prepare silver ammonia solution: 20g / L AgNO 3 , add ammonia water dropwise until clarified; then prepare a reducing solution: glucose 60g / L, tartaric acid 3g / L, ethanol 150mL / L, ethylenediamine 20mL / L....

Embodiment 3

[0044] (1) Prepare an acidic potassium permanganate solution, containing 10 g of potassium permanganate and 150 g of phosphoric acid per liter of the solution, immerse the aramid fibers, ultrasonically treat them for 20 minutes at 50° C., then take out the fibers, wash them, and dry them.

[0045] (2) dissolving chitosan with a mass concentration of 3% acetic acid solution, chitosan solution concentration 15g / L, control temperature at 10°C, add 5ml of adipaldehyde solution dropwise at a speed of 10s / drop, and stir for 20 minutes , and then immersed in the aramid fiber, raised to room temperature, padding, the liquid rolling rate is 100%, and then baked at 160 ° C.

[0046] (3) Prepare a 100mg / L palladium chloride solution, immerse in the fabric at 40°C for 60 minutes, and dry at 50°C.

[0047] (4) First prepare silver ammonia solution: 30g / L AgNO 3 , add ammonia water dropwise until clarified; then prepare reducing solution: glucose 80g / L, tartaric acid 5g / L, ethanol 200mL / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com