Dyeing method of wool textile with low energy consumption and low damage and wool fabric

A dyeing method and low energy consumption technology, applied in the field of dyeing and finishing, can solve problems such as unstable effects, and achieve the effects of saving process time, energy and less damage to wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

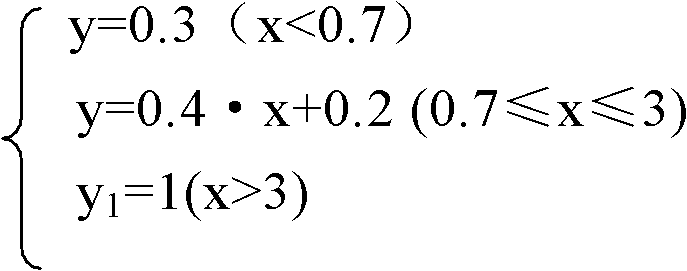

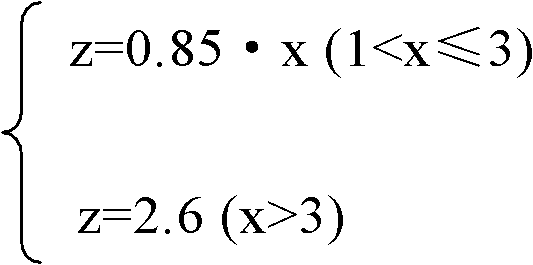

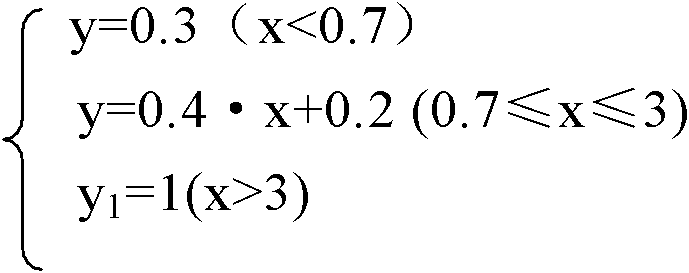

Image

Examples

Embodiment 1

[0043] In this embodiment, the wool of the woolen fabric is dyed into a light color with a reactive dye, and the consumption of the dye is 0.5% (o.w.f). The woolen fabric in this embodiment is a wool jersey with spandex, specifically the 72N / 1 Yangtze shrink-resistant wool (compact spinning 18.9 fineness)+20D low-temperature type LYCRA (Lycra) produced by Shanghai Jialinjie Textile Co., Ltd. ) fully lined with spandex single jersey, the weight is 140g / m 2 , the width is 150cm, the weight is 20 kilograms, and the wool content is 95.6wt%.

[0044] In a jet dyeing machine, the method of dyeing the woolen fabric includes the following steps:

[0045] a 2 ) pretreatment process: inject industrial soft water into the jet dyeing machine at a bath ratio of 1:15, put the woolen fabric into the jet dyeing machine, record the water level at this time, add degreaser and sodium sulfate, and the amount of degreaser is Every 1 liter of water 2g, the consumption of sodium sulfate is 3% (o....

Embodiment 2

[0051] In this embodiment, the wool of the woolen fabric is dyed into a neutral color with a reactive dye, and the consumption of the dye is 2% (o.w.f). The wool fabric is wool single jersey with spandex, specifically 72N / 1 Yangtze shrink-resistant wool (compact spinning 18.9 fineness) + 20D low temperature type LYCRA (Lycra) full lined spandex jersey produced by Shanghai Jialinjie Textile Co., Ltd. , the weight is 140g / m 2 , the width is 150cm, the weight is 20 kilograms, and the wool content is 95.6wt%.

[0052] In the jet dyeing machine, the method for dyeing the woolen fabric comprises the following steps:

[0053] a 1 ) pretreatment process: inject industrial soft water into the jet dyeing machine at a bath ratio of 1:15, put the woolen fabric into the jet dyeing machine, record the water level at this time, add degreaser and sodium sulfate, and the amount of degreaser is Every 1 liter of water 1.5g, the consumption of sodium sulfate is 5% (o.w.f), then add sodium carb...

Embodiment 3

[0060] In this embodiment, the wool of the woolen fabric is dyed into a dark color with a reactive dye, and the consumption of the dye is 4% (o.w.f). The wool fabric is wool single jersey with spandex, specifically 72N / 1 Yangtze shrink-resistant wool (compact spinning 18.9 fineness) + 20D low temperature type LYCRA (Lycra) full lined spandex jersey produced by Shanghai Jialinjie Textile Co., Ltd. , the weight is 140g / m 2 , the width is 150cm, the weight is 20 kilograms, and the wool content is 95.6wt%.

[0061] In a jet dyeing machine, the method of dyeing the woolen fabric includes the following steps:

[0062] a 1 ) pretreatment process: inject industrial soft water into the jet dyeing machine at a bath ratio of 1:15, put the woolen fabric into the jet dyeing machine, record the water level at this time, add degreaser and sodium sulfate, and the amount of degreaser is Every 1 liter of water 1g, the consumption of sodium sulfate is 2% (o.w.f), then add sodium carbonate 0.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com