Preparation method of modified nano titanium dioxide finishing agent with uvioresistant and self-cleaning double effects

A nano-titanium dioxide, self-cleaning technology, applied in the field of material science, can solve the problems of accelerating skin aging, harming the human body, etc., and achieves the effects of industrial production, strong practicability, and simple operation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

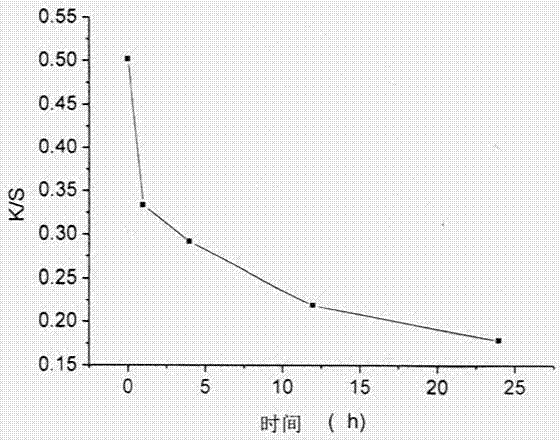

[0017] The finishing method that rutile type nano-titanium dioxide has ultraviolet absorption and self-cleaning performance to polyester-cotton fabric is characterized in that it is prepared through the following steps:

[0018] (1) Add the rutile nano-titanium dioxide powder into the ethanol solution to form an ethanol solution with a mass concentration of 5%, and ultrasonically treat it for a period of time so that the nano-titanium dioxide powder is evenly dispersed in the ethanol solution.

[0019] (3) Add 1% silane coupling agent according to the mass of titanium dioxide to the ethanol solution in (1), adjust the pH to neutral, stir evenly, and react at a constant temperature of 80° C. for 2 hours to obtain a modified nano-titanium dioxide finishing solution.

[0020] (3) Polyester cotton is arranged in the modified nano-titanium dioxide finishing liquid, and two dipping and two rolling are adopted, and the rolling ratio reaches 80%, so that the titanium dioxide is uniform...

Embodiment 2

[0023] The finishing method that rutile type nano-titanium dioxide has ultraviolet absorption and self-cleaning performance to polyester-cotton fabric is characterized in that it is prepared through the following steps:

[0024] (1) Add the rutile nano-titanium dioxide powder into the ethanol solution to form an ethanol solution with a mass concentration of 4%, and ultrasonically treat it for a period of time to make the nano-titanium dioxide powder uniformly disperse in the ethanol solution.

[0025] (3) Add 2% silane coupling agent according to the mass of titanium dioxide to the ethanol solution in (1), adjust the pH to neutral, stir evenly, react at a constant temperature of 80° C. for 3 hours, and obtain the modified nano-titanium dioxide finishing solution.

[0026] (3) Polyester cotton is arranged in the modified nano-titanium dioxide finishing liquid, and two dipping and two rolling are adopted, and the rolling ratio reaches 70%, so that the titanium dioxide is uniforml...

Embodiment 3

[0029] The finishing method that rutile type nano-titanium dioxide has ultraviolet absorption and self-cleaning performance to polyester-cotton fabric is characterized in that it is prepared through the following steps:

[0030] (1) Add the rutile nano titanium dioxide powder into the ethanol solution to form an ethanol solution with a mass concentration of 3%, and ultrasonically treat it for a period of time to make the nano titanium dioxide powder uniformly disperse in the ethanol solution.

[0031] (3) Add 3% silane coupling agent according to the mass of titanium dioxide to the ethanol solution in (1), adjust the pH to neutral, stir evenly, and react at a constant temperature of 80° C. for 1 hour to obtain a modified nano-titanium dioxide finishing solution.

[0032] (3) Polyester cotton is arranged in the modified nano-titanium dioxide finishing liquid, and two dipping and two rolling are adopted, and the excess rolling rate reaches 60%, so that the titanium dioxide is eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com